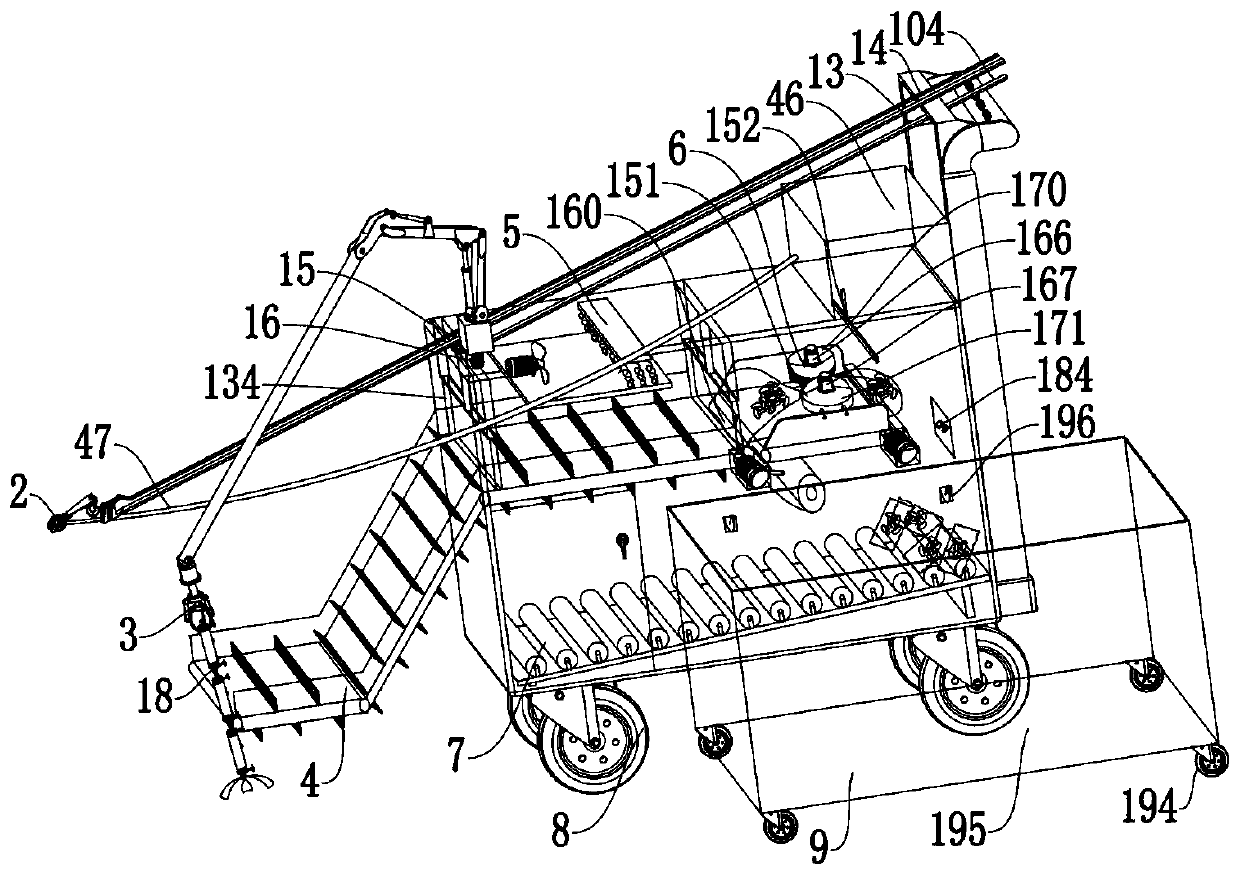

[0008] Further, the picking device for supporting the atomized flow wrapped by the liquid bag includes a picking fixing

assembly, a picking

assembly of the liquid bag wrapped atomizing flow supporting type, and a picking drive

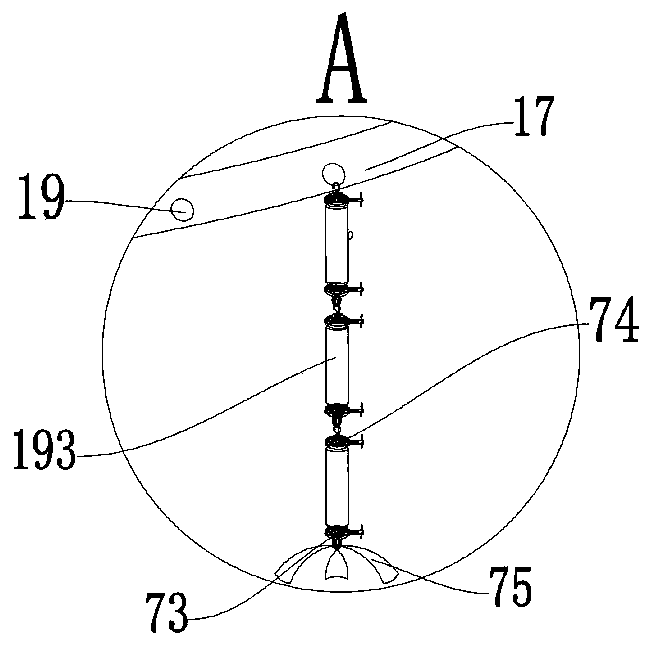

assembly. On the picking device, the picking driving assembly is arranged on one end of the picking fixing assembly close to the picking fixing connecting rod, and the liquid bag-wrapped atomized flow supporting type picking assembly is arranged on the end of the picking fixing assembly away from the picking fixing connecting rod, The picking and fixing component plays a fixed and supporting role for the liquid bag-wrapped atomized flow supporting type picking component and the picking driving component; the picking and fixing component includes the atomized flow supporting picking bracket, picking fixing part 1, picking fixing part 2, picking protection Shell one and picking protective shell two, the atomized flow supporting picking bracket is provided with left and right shaking picking connectors, and the atomized flow supporting picking bracket is fixed to the horizontal shaking picking device through the left and right shaking picking connecting parts On the top, the left and right swaying picking connector plays a role of fixed connection to the liquid bag wrapped atomized flow supporting picking device and the human-like horizontal shaking type picking device. One end of the picking fixing part 1 and picking fixing part 2 is arranged On one end of the supporting picking bracket far away from the picking device that imitates the horizontal shaking of human hands, a certain gap is provided between the picking fixing piece 1 and the picking fixing piece 2, and the picking protective shell 1 is arranged on the picking fixing piece 1 perpendicular to the horizontal plane. On the other end, the picking protective shell 2 is vertically arranged on the other end of the picking fixture 2, the picking protective shell 1 and the picking protective shell 2 are arranged in a hollow cavity with an opening at one end, and the picking protective shell 1 The cross-section of the picking protective shell 2 is in a concave shape, the picking protective shell 1 and the concave-shaped gap of the picking protective shell 2 are oppositely arranged, and the concave-shaped gap of the picking protective shell 1 is provided with an atomization flow assembly. Cavity 1, the concave-shaped gap of the picking protection shell 2 is provided with the atomization flow

component placement cavity 2, and the liquid bag wraps the atomization flow supporting type picking component in the atomization flow component to place cavity 1 and the atomization flow component There are two sets of two groups symmetrically arranged in the second placement cavity, which are the liquid bag-wrapped atomized flow supporting type picking component 1 and the liquid bag wrapped atomized flow supporting type picking component 2, and the liquid bag wrapped atomized flow supporting type The first type picking component is set in the atomization flow

component placement cavity one, and the liquid bag wrapping atomization flow support type picking component two is set in the atomization flow

component placement cavity two; the liquid bag wraps the atomization flow support The type picking assembly one includes liquid bag one and air bag one, and the liquid bag one and air bag one are arranged in the atomizing flow assembly placement cavity one in order from the inside to the outside of the opening of the picking protection shell one, and the liquid bag one It is fixedly connected to the inner wall of the picking protection shell 1, the liquid bag 1 is arranged in a hollow sac shape, and the side of the liquid bag 1 far away from the picking protection shell 1 is evenly arranged with atomizing sheets, and the air bag 1 is arranged through the liquid One side of the

capsule one is provided with an atomizing sheet, and the opposite side of the

airbag one away from the atomization sheet is provided with an atomizing flow hole one. Preferably, both the liquid

capsule one and the

airbag one are made of rubber materials, and the rubber has good Sealing, elasticity, softness and tensile strength, the atomizing sheet is MYS-16 model, powered by 3-12V

voltage, the amount of atomization can reach To 15-680ml / h, the atomizing sheet uses the principle of

ultrasound to break up the

liquid water molecule structure in the liquid

capsule 1 into tiny water droplets through the high-frequency

resonance of the atomizing sheet to generate mist. The mist generated by the

liquid water high-frequency

resonance is inflated to the

airbag-1 and at the same time discharged through the atomization flow hole on the outside of the airbag-1. The two sides of the airbag-1 away from the atomization sheet and close to the picking protective shell are respectively equipped with

memory foam One and

memory foam two, said

memory foam one and memory foam two are relatively L-shaped settings, the length between memory foam one and memory foam two upper ends is greater than the

diameter of the mushroom

handle and less than the

diameter of the mushroom cap, memory foam one The length between the memory foam II and the lower end is less than the

diameter of the shiitake mushroom shank. The

structure and function of the liquid bag-wrapped atomized flow supporting type picking

component II is exactly the same as that of the liquid bag-wrapped atomized flow supporting type picking component I. The liquid bag wrapped The atomized flow supporting type picking component 2 includes a liquid bag 2 and an air bag 2, and the liquid bag 2 and the air bag 2 are arranged in the atomized flow component placement cavity 2 in order from the inside to the outside of the opening of the picking protection shell 2, The liquid bag two is fixedly connected to the inner wall of the picking protection shell two, and the liquid bag two is arranged in a hollow

capsule shape, and the side of the liquid bag two far away from the picking protective shell two is evenly arranged with atomizing sheets, and the air bag The second hole is set on the side of the liquid bag 2 where the atomizing sheet is provided, and the opposite side of the air bag 2 away from the atomizing sheet is provided with the atomizing flow hole 2, and the atomizing sheet uses the ultrasonic principle to pass through the high-frequency

resonance of the atomizing sheet Break up the

liquid water molecular structure in the liquid capsule 2 into tiny water droplets to produce mist spray. Preferably, both the liquid capsule 2 and the air capsule 2 are made of rubber materials, and the rubber has good sealing performance, elasticity, and softness. The mist produced by the high-frequency resonance of the atomizing sheet on the liquid water inflates the air bag two and at the same time discharges it through the atomization flow hole two outside the air bag two, abandoning the use of

solid picking in traditional picking that is easy to be damaged. The soft surface of

shiitake mushrooms creatively combines the principle of extraction with the principle of air pressure or

hydraulic structure (using gas or liquid parts to replace the

solid structure in the object), using the cooperation of liquid bag one, air bag one and liquid bag two, air bag two, through The supporting effect of the relative atomized

airflow solves the contradictory technical problem of not only touching the

shiitake mushrooms but not destroying the tender fresh shiitake mushrooms when picking, and also achieves the technical effect of not destroying the mushroom sticks and surrounding small mushrooms in the case of dense growth In a real sense, the technical effect of complete wrapping and zero-damage picking of shiitake mushrooms is realized. The two sides of the airbag two away from the atomization sheet and close to the picking protective shell are respectively provided with memory foam three and memory foam four. The memory foam Three and memory foam four are arranged in an L-shape relative to each other. The length between the upper ends of memory foam three and memory foam four is greater than the diameter of the mushroom

handle and less than the diameter of the mushroom cap. The length between the memory foam three and memory foam four lower ends is less than The diameter of the shiitake shank, when air bag 1 is inflated, memory foam 1 and memory foam 2 are driven to move toward the mushrooms to be picked, and when air bag 2 is inflated, memory foam 3 and memory foam 4 are driven to the direction of the mushrooms to be picked, which is the direction relative to air bag 1 When moving, when airbags 1 and 2 are inflated, memory foam 1,

Memory foam two, memory foam three and memory foam four upper ends surround the cavity diameter greater than the diameter of the mushroom

handle and less than the diameter of the mushroom cap, memory foam one, memory foam two, memory foam three and memory foam four lower ends surrounded The diameter of the cavity is smaller than the diameter of the shiitake mushroom handle.

Memory foam 1, memory foam 2, memory foam 3 and memory foam 4 play the role of assisting in picking shiitake mushrooms.

Memory foam two, memory foam three and the cavity surrounded by memory foam can assist the flexible support of mushrooms to prevent mushrooms from falling from the side or the lower end; The

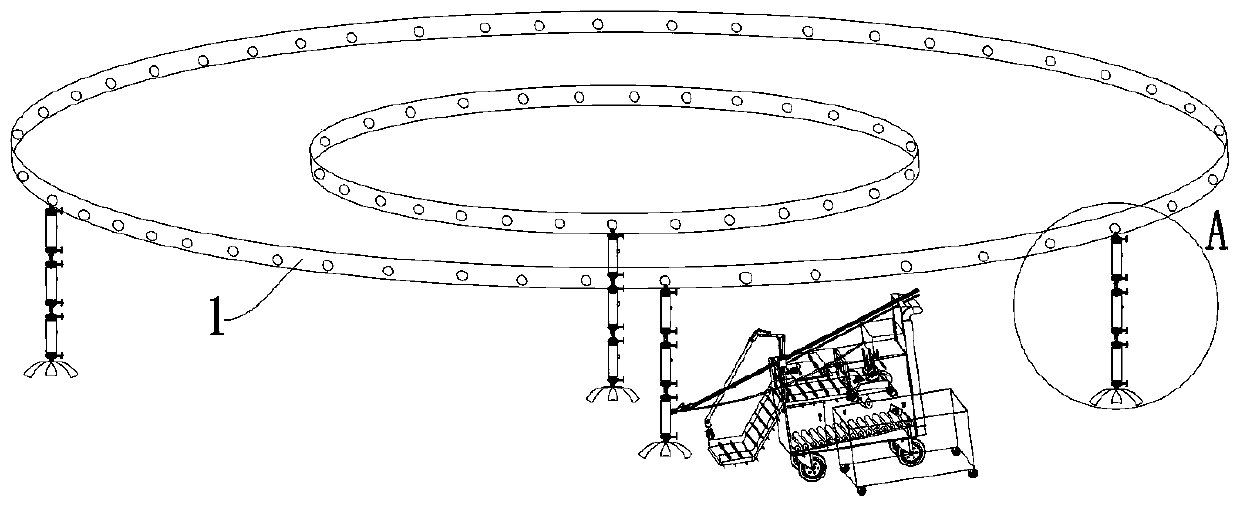

water storage tank is fixed on the portable

mobile device, and the portable

mobile device acts as a fixed support for the

water storage tank. The water pump and the micro

air pump are provided on the atomizing flow supporting picking bracket, and the atomizing The flow supporting picking bracket plays a fixed role for the water pump and the micro

air pump. The water pump uses the JT-160A model and is powered by 12V

voltage. The

water flow rate can reach up to 4L / min. The water inlet

pipe is located between the water pump and the

water storage tank. , one end of the

water supply pipe is arranged at the water outlet of the water pump, and the other end of the

water supply pipe passes through the picking protective shell one and the picking protective shell two respectively and is respectively arranged on the liquid bag one and the liquid bag two, and the micro

air pump is The charging and suction dual-purpose pump, the micro air pump is 4A12B25R37 model, powered by 12V

voltage, the no-load flow rate can reach 13L / min, the charging and discharging air pipe is located between the micro air pump and air bag 1, the micro air pump and air bag 2, and the micro air pump The air pump inflates and deflates the first airbag and the second airbag through the inflation and deflation pipe. When the atomization flow generated by the

vaporization of liquid water by the atomization sheet is small, the atomization flow is not enough to fill the first airbag and the second airbag. When the micro-air pump is in the inflated state, the micro-air pump assists the atomization gas to fill the first air bag and the second air bag. When the air is full, only the

airflow discharged through the atomization flow hole 1 and the atomization flow hole 2 is too small. At this time, the micro-air pump is in the pumping state, and the micro-air pump assists the atomization flow hole 1 and the atomization flow hole 2 to reduce the air bag 1 and The gas in the air bag 2, in order to better support the shiitake mushrooms without damaging them

Login to View More

Login to View More  Login to View More

Login to View More