Quantitative determination method for medium-chain triglycerides in tobacco breakable bead solvent

A technology for quantitative determination of caprylic acid glyceride, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of not achieving quantitative determination, and is not suitable for quantitative detection of caprylic acid glyceride in explosive beads for cigarettes, etc. The effect of small signal error, high sensitivity and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

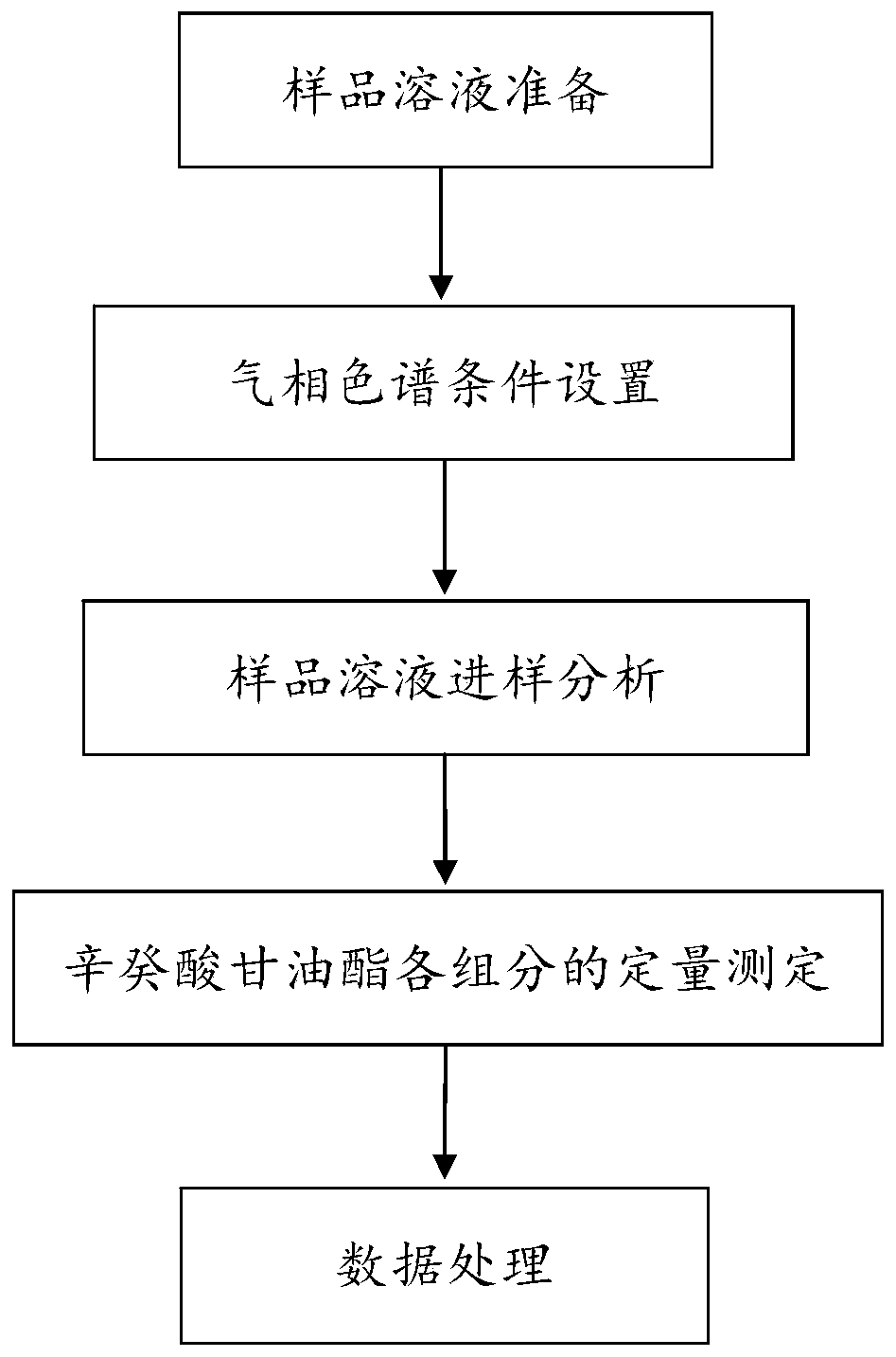

[0042] The assay method of caprylic acid glyceride in the quick-fried pearl for cigarette of the present embodiment, such as figure 1 described, including the following steps:

[0043] 1) Preparation of the solution to be tested: Take 3 regular cigarette popping beads of brand 1 in a centrifuge tube, add 15mL of extractant ethanol and 0.0813mL ethanol solution of tricaproin with a concentration of 40mg / mL, squeeze the popping beads After breaking, place the centrifuge tube in a vortex shaker to extract for 15 minutes, take 1mL supernatant and filter to obtain the test solution;

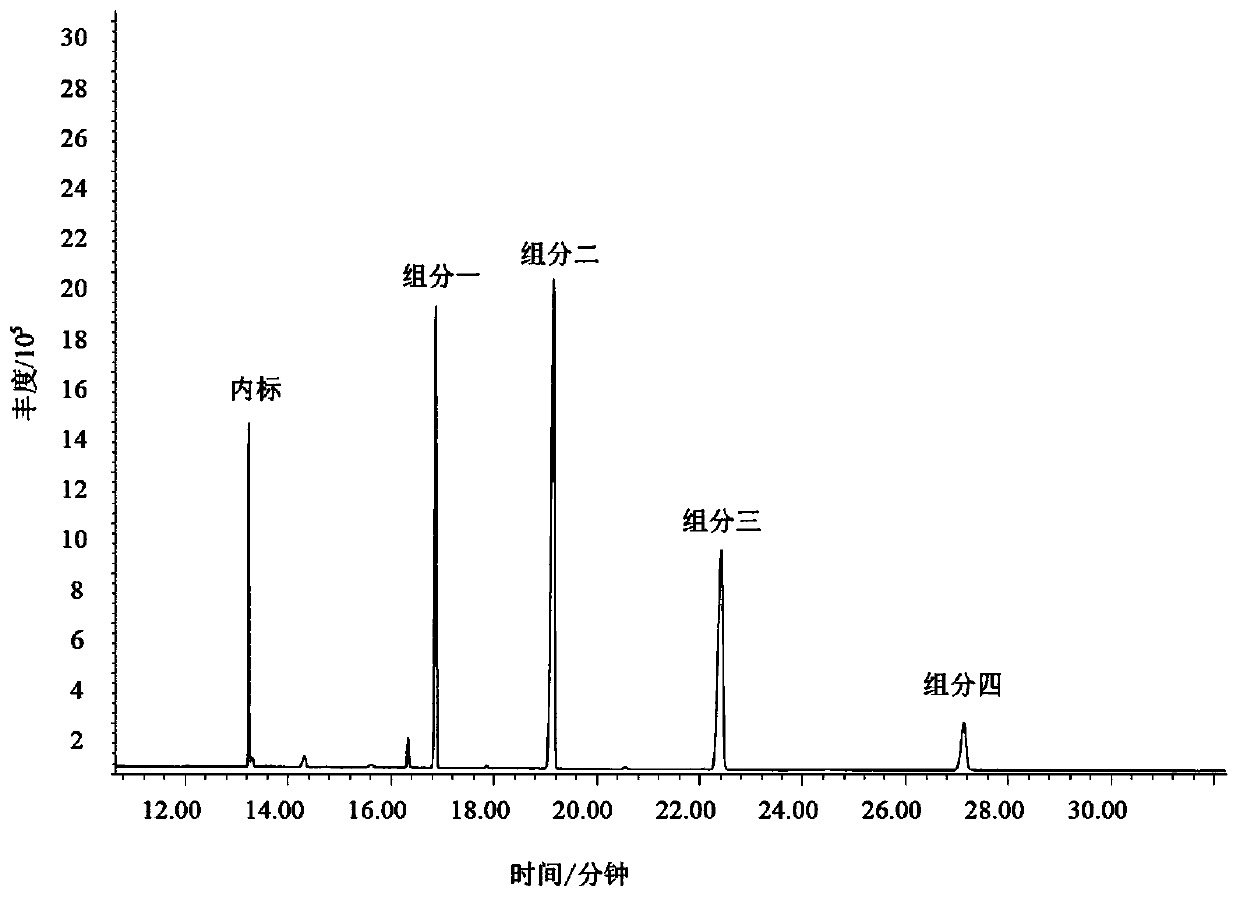

[0044] 2) Preparation of standard working solution: glyceryl tricaprylate, glyceryl dicaprylate monocaprate, glyceryl monocaprylate dicaprate, glyceryl tricaprate as standard substances, glyceryl tricaproate as internal standard, ethanol As a solvent, a series of standard working solutions were prepared, and the specific concentrations are shown in Table 1. Among them, three caprylic acid glycerides...

Embodiment 2

[0050] The quantitative determination method of glyceryl caprylate in the quick-fried pearl solvent for cigarettes of the present embodiment comprises the following steps:

[0051] 1) Preparation of the solution to be tested: Take 3 conventional cigarette popping beads of brand 2 in a centrifuge tube, add 15mL extractant acetone and 0.0813mL acetone solution of tricaproin with a concentration of 40mg / mL, squeeze the popping beads After breaking, the centrifuge tube was placed in a vortex shaker for 15 minutes of shaking and extraction, and 1 mL of the supernatant was filtered to obtain the test solution;

[0052] 2) prepare standard working solution: method is the same as embodiment 1;

[0053] 3) making of standard working curve: method is the same as embodiment 1;

[0054] 4) Determination of the liquid to be tested: the determination method is the same as in Example 1, and the determination results are shown in Table 3.

Embodiment 3

[0056] The assay method of glyceryl caprylate in the quick-fried pearls for cigarettes of the present embodiment comprises the following steps:

[0057] 1) Preparation of the solution to be tested: Take 4 brand 3 slim cigarette beads and put them in a centrifuge tube, add 15mL extractant dichloromethane and 0.0813mL tricaproin dichloromethane solution with a concentration of 40mg / mL , squeeze the blasting beads, then place the centrifuge tube in a vortex shaker for 20 minutes of shaking and extraction, take 1mL of the supernatant and filter to obtain the test solution;

[0058] 2) prepare standard working solution: method is the same as embodiment 1;

[0059] 3) making of standard working curve: method is the same as embodiment 1;

[0060] 4) Determination of the liquid to be tested: the determination method is the same as in Example 1, and the determination results are shown in Table 3.

[0061] The detection result of caprylic capric acid glyceride component in the testing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com