High-temperature-resistant modified titanium dioxide crosslinking agent for cracking liquid and preparation method thereof

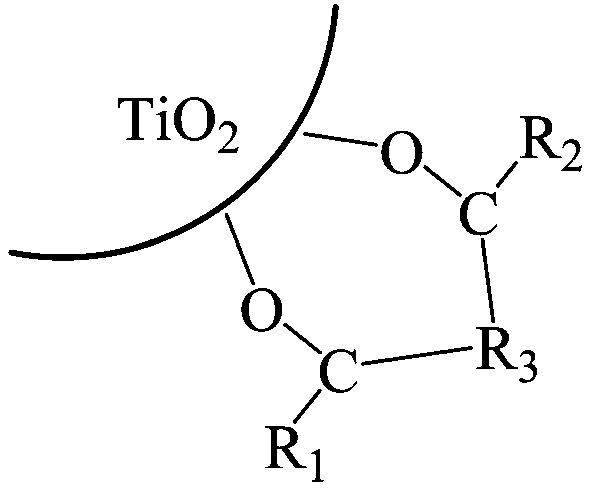

A technology of nano-titanium dioxide and cross-linking agent, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of being unable to adapt to fracturing construction, etc., and achieve simple and reliable experimental methods, good temperature resistance and shear resistance cutting performance, the effect of tight three-dimensional network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a high-temperature-resistant modified nano-titanium dioxide crosslinking agent for fracturing fluid, comprising the following steps:

[0029] (1) Preparation of nano-titanium dioxide: adjust the pH value of the alcohol to 2-4 with hydrochloric acid, then slowly add an inorganic titanium source to the alcohol solution, and stir for 15 minutes; react the mixed solution at 70°C for 60 minutes to obtain a white suspension; Wash the obtained white suspension with ether, centrifuge the solution, take the white solid and disperse it in a mixed solution of deionized water and ethanol to obtain a nano-titanium dioxide dispersion;

[0030] Wherein, the mass ratio of the alcohol to the inorganic titanium source is 85:15; the alcohol is ethanol; the inorganic titanium source is titanium tetrachloride;

[0031] (2) Preparation of modified nano-titanium dioxide cross-linking agent: adding an organic ligand with a mass fraction of 20% to the prepared nano-titani...

Embodiment 2

[0033] A method for preparing a high-temperature-resistant modified nano-titanium dioxide crosslinking agent for fracturing fluid, comprising the following steps:

[0034] (1) Preparation of nano-titanium dioxide: adjust the pH value of the alcohol to 2-4 with hydrochloric acid, then slowly add an inorganic titanium source to the alcohol solution, and stir for 15 minutes; react the mixed solution at 90°C for 50 minutes to obtain a white suspension; Wash the obtained white suspension with ether, centrifuge the solution, take the white solid and disperse it in a mixed solution of deionized water and ethanol to obtain a nano-titanium dioxide dispersion;

[0035] Wherein, the mass ratio of the alcohol to the inorganic titanium source is 90:10; the alcohol is benzyl alcohol; the inorganic titanium source is butyl titanate;

[0036] (2) Preparation of modified nano-titanium dioxide crosslinking agent: adding an organic ligand with a mass fraction of 25% to the prepared nano-titanium...

Embodiment 3

[0038] A method for preparing a high-temperature-resistant modified nano-titanium dioxide crosslinking agent for fracturing fluid, comprising the following steps:

[0039] (1) Preparation of nano-titanium dioxide: adjust the pH value of the alcohol to 2-4 with hydrochloric acid, then slowly add an inorganic titanium source to the alcohol solution, and stir for 15 minutes; react the mixed solution at 80°C for 80 minutes to obtain a white suspension; Wash the obtained white suspension with ether, centrifuge the solution, take the white solid and disperse it in a mixed solution of deionized water and ethanol to obtain a nano-titanium dioxide dispersion;

[0040] Wherein, the mass ratio of the alcohol to the inorganic titanium source is 88:12; the alcohol is glycerol; the inorganic titanium source is isopropyl titanate;

[0041] (2) Preparation of modified nano-titanium dioxide crosslinking agent: adding an organic ligand with a mass fraction of 22% to the prepared nano-titanium d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

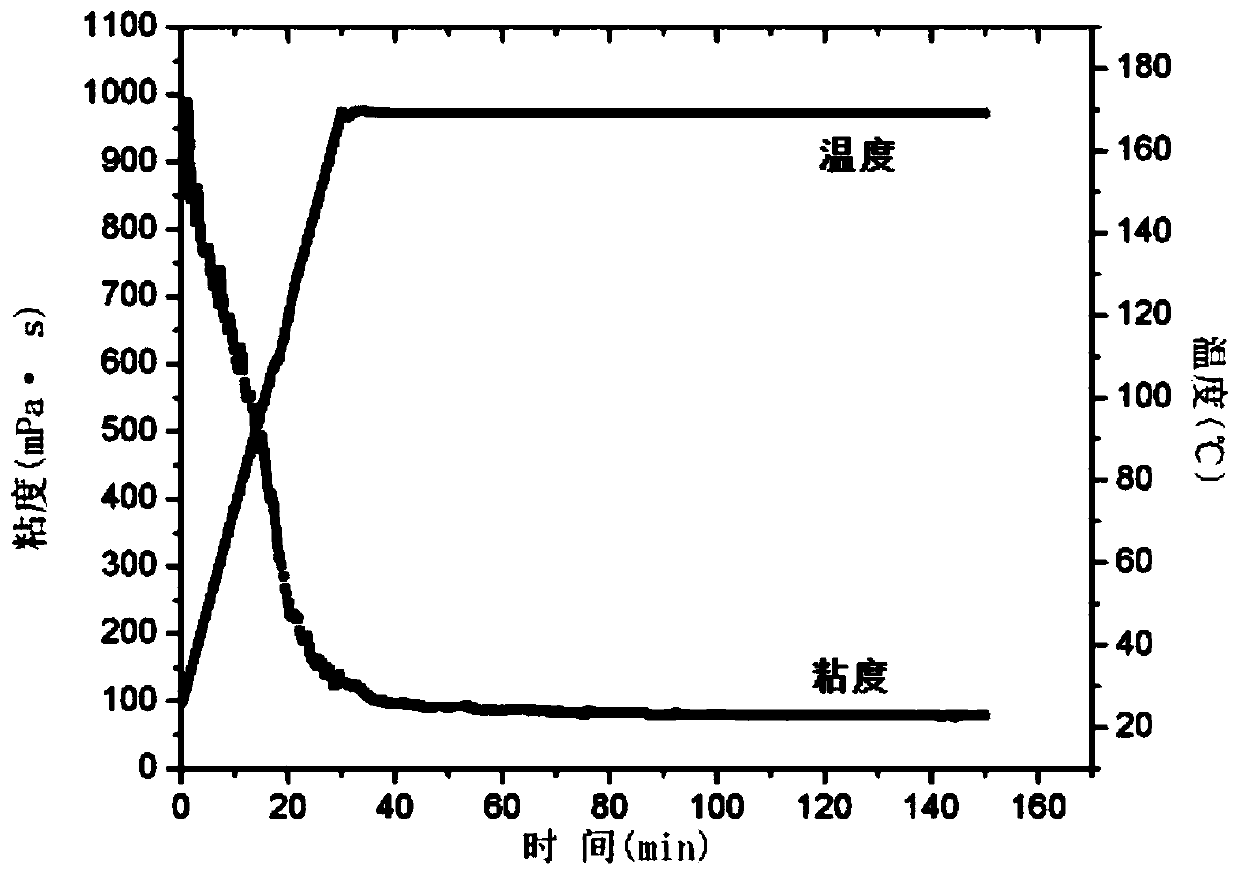

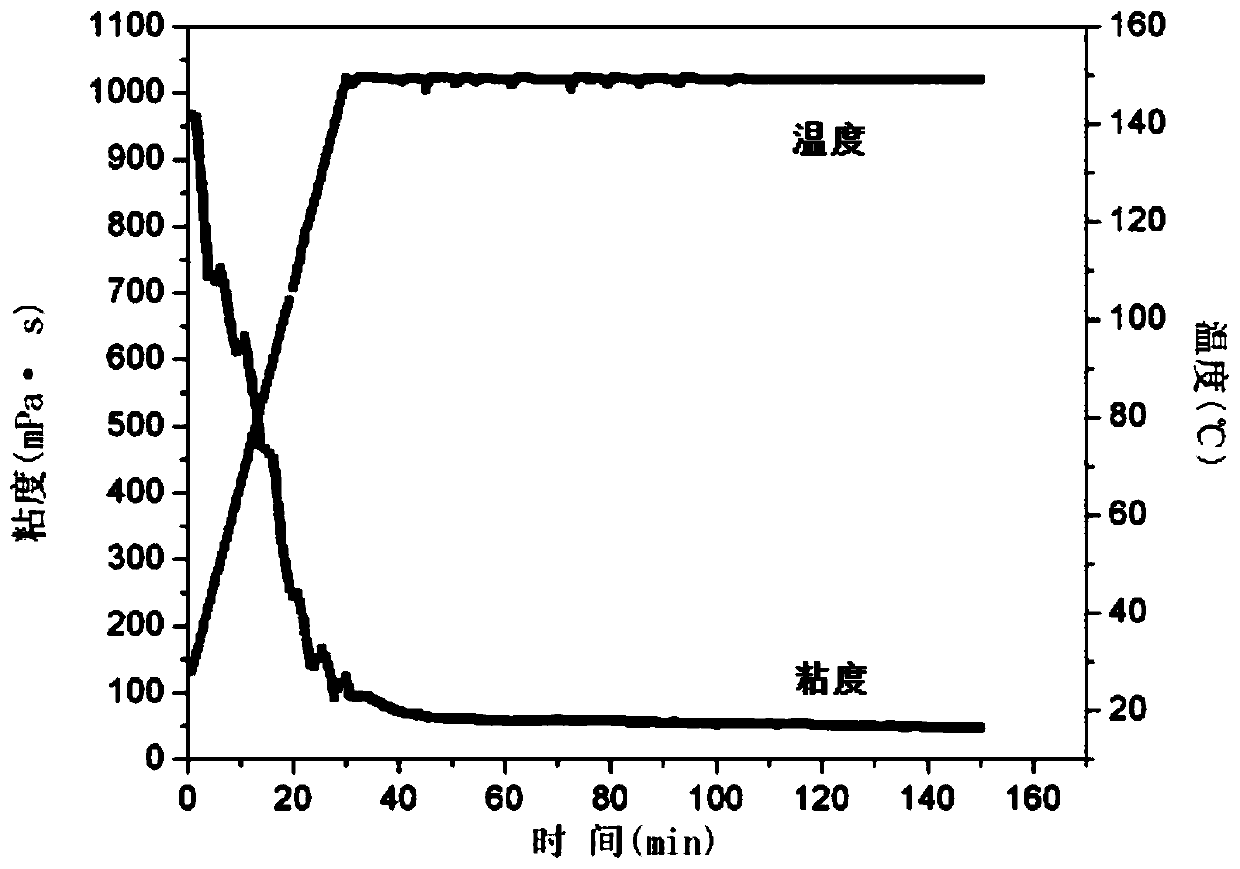

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com