Antioxidant coating as well as preparation method and application thereof

The technology of anti-oxidation coating and diboron trioxide is applied in alkali metal silicate coatings, coatings, devices for coating liquid on the surface, etc. To achieve the effect of reducing the preparation process, wide source of raw materials, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

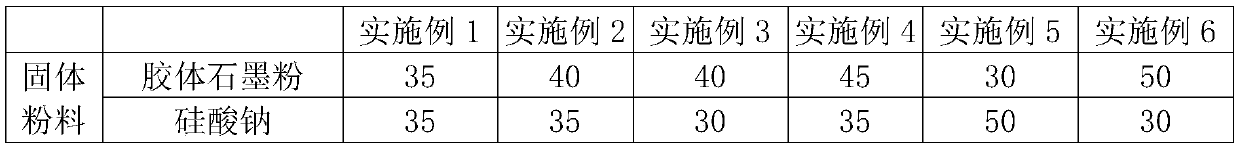

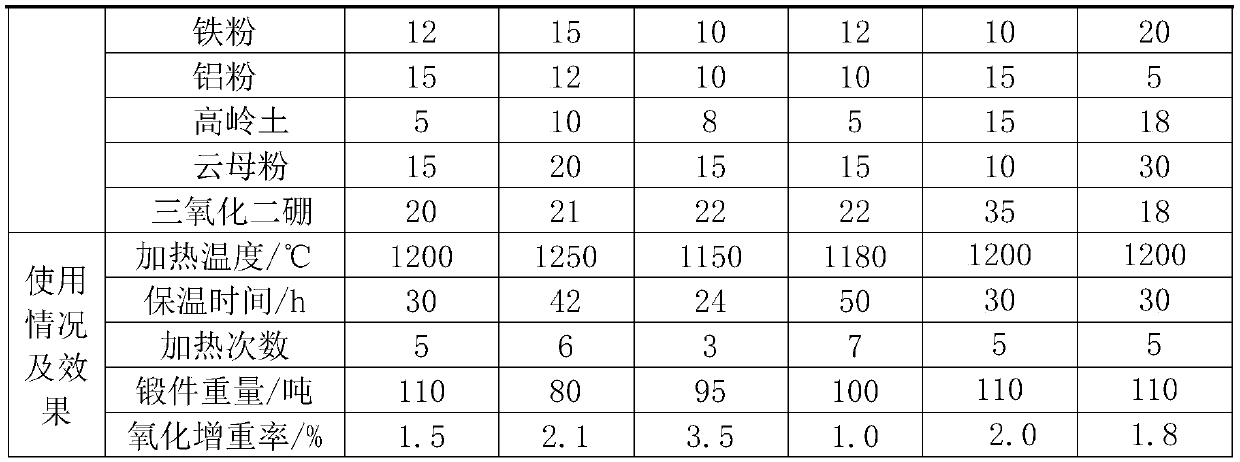

Embodiment 1

[0044] Weigh 35 parts of colloidal graphite powder, 35 parts of sodium silicate, 12 parts of metal iron powder, 15 parts of metal aluminum powder, 5 parts of kaolin, 15 parts of mica powder, and 20 parts of diboron trioxide. All the above are parts by weight. Put it in a V-shaped mixer and mix it at high speed for 120 minutes to obtain the heat-treated anti-oxidation coating for carbon steel or alloy steel of the present invention.

[0045] Among them, the fineness of colloidal graphite powder is 320 mesh, the fineness of sodium silicate is 120 mesh, the fineness of diboron trioxide is 120 mesh, the fineness of kaolin and mica powder is 320 mesh, the fineness of metal iron powder is 400 mesh, The fineness of the metal aluminum powder is 320 mesh.

[0046] Coating process: The paint is coated on a 110-ton SA508 steel forging with a compressed air spraying device, the coating thickness is not less than 0.20mm, and the surface temperature of the forging is 80°C.

[0047] Heating...

Embodiment 2

[0049] Weigh 40 parts of colloidal graphite powder, 35 parts of sodium silicate, 15 parts of metal iron powder, 12 parts of metal aluminum powder, 10 parts of kaolin; 20 parts of mica powder and 21 parts of diboron trioxide. All the above are parts by weight; put it in a ball mill and mix it at high speed for 100 minutes to obtain the heat-treated anti-oxidation coating for carbon steel or alloy steel of the present invention.

[0050] Among them, the fineness of colloidal graphite powder is 320 mesh, the fineness of sodium silicate is 120 mesh, the fineness of diboron trioxide is 120 mesh, the fineness of kaolin and mica powder is 320 mesh, the fineness of metal iron powder is 400 mesh, The fineness of the metal aluminum powder is 320 mesh.

[0051] Coating process: The paint is coated on 80 tons of 18MND5 steel forgings with a high-pressure airless spraying device, the coating thickness is not less than 0.20mm, and the surface temperature of the forgings is 950°C.

[0052] ...

Embodiment 3

[0054] Weigh 40 parts of colloidal graphite powder, 30 parts of sodium silicate, 10 parts of metal iron powder, 10 parts of metal aluminum powder, 8 parts of kaolin; 15 parts of mica powder and 22 parts of diboron trioxide. All the above are parts by weight; place it in a VH high-efficiency mixer and mix it at high speed for 80 minutes to obtain the heat-treated anti-oxidation coating for carbon steel or alloy steel of the present invention.

[0055] Among them, the fineness of colloidal graphite powder is 320 mesh, the fineness of sodium silicate is 120 mesh, the fineness of diboron trioxide is 120 mesh, the fineness of kaolin and mica powder is 320 mesh, the fineness of metal iron powder is 400 mesh, The fineness of the metal aluminum powder is 320 mesh.

[0056] Coating process: The paint is coated on 95 tons of 18MND5 steel forgings with a high-voltage electrostatic spraying device, the coating thickness is not less than 0.20mm, and the surface temperature of the forgings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com