Preparation method of 2,5-dihydroxybenzaldehyde

A technology of dihydroxybenzaldehyde and dimethoxybenzaldehyde, which is applied in the field of preparation of important intermediate 2,5-dihydroxybenzaldehyde, can solve the problem of low cost, achieve mild preparation conditions, strong industrial application value, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

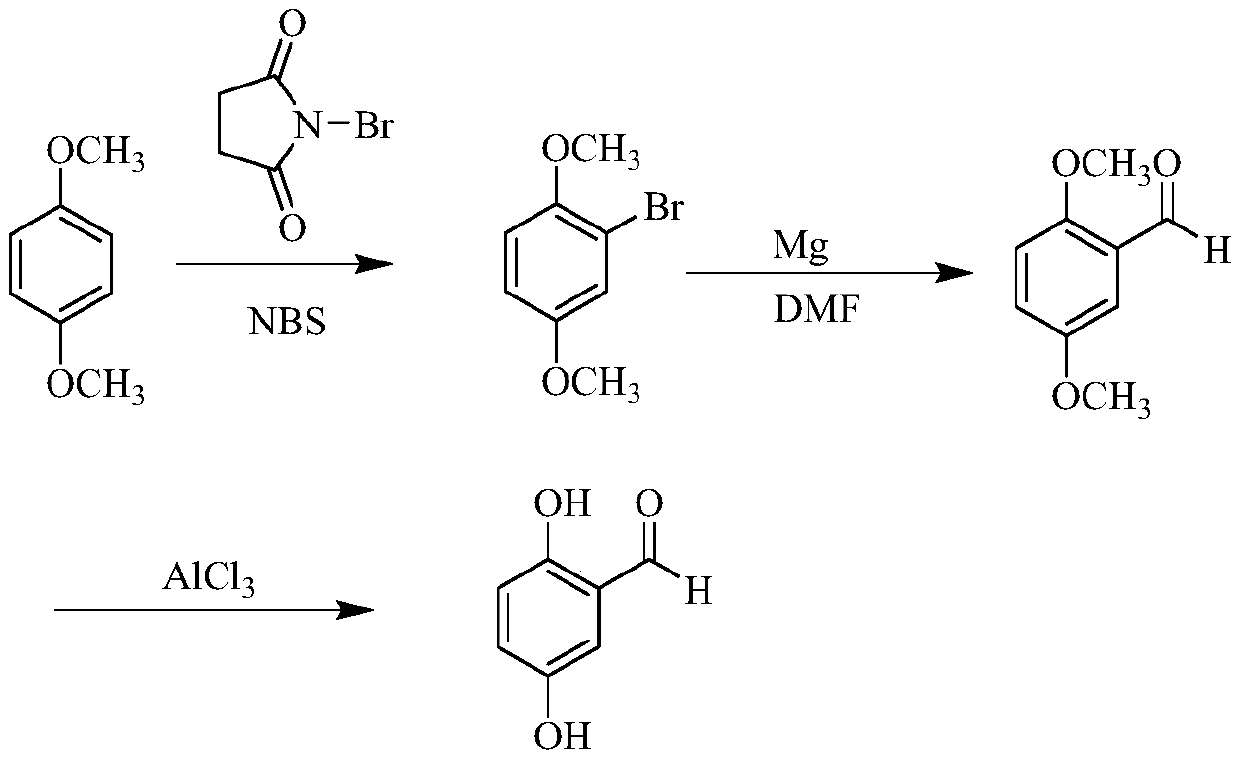

[0014] 1) Synthesis of 2,5-dimethoxybromobenzene

[0015] Add 38.5g (278.6mmol) of terephthalic ether and 120g of N,N-dimethylformamide (DMF) to a 500ml four-necked flask. Stir mechanically at room temperature until it is completely dissolved. Cool down to 10℃ and add 45g slowly. (252.8mmol) The solution prepared by N-bromosuccinimide and N,N-dimethylformamide, drip in about 1 hour, react for 1 hour, slowly add 200ml of water to the reaction solution at room temperature, add Dichloroethane (100mL) was extracted twice, the organic layer was extracted with saturated brine (100mL), the organic layer was dried over anhydrous sodium sulfate overnight, filtered with suction, and the filtrate was evaporated to remove the solvent to obtain a brownish yellow liquid 2,5-dimethoxy Bromobenzene 49.3g.

[0016] 2) Synthesis of 2,5-Dimethoxybenzaldehyde

[0017] Add 7.5g (312.5mmol) of magnesium powder, 35g of tetrahydrofuran (THF) to a 500mL four-necked flask, under nitrogen protection, add 50g...

Embodiment 2

[0021] 1) Synthesis of 2,5-dimethoxybromobenzene

[0022] Add 38.5g (278.6mmol) terephthalic ether and 150g N,N-dimethylformamide to a 500ml four-necked flask, stir mechanically at room temperature until it is completely dissolved, and slowly add 49.6g (278.6mmol) dropwise to 10℃. ) The solution prepared by N-bromosuccinimide and N,N-dimethylformamide, drip in about 1 hour, react for 1 hour, slowly add 200ml of water to the reaction solution at room temperature, add dichloroethane Extraction with alkane (100 mL), extract the organic layer with saturated brine (100 mL), dry the organic layer with anhydrous sodium sulfate overnight, filter with suction, and rotate the filtrate to obtain 51 g of brown liquid.

[0023] 2) Synthesis of 2,5-Dimethoxybenzaldehyde

[0024] Add 11g (460mmol) of magnesium powder, 50g of tetrahydrofuran and nitrogen protection to a 500mL four-necked flask. Add 10 drops of a solution of 50g (230.3mmol) of 2,5-dimethoxybromobenzene and tetrahydrofuran under mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com