Oil sludge treatment method and system

A treatment method and technology of a treatment system, which are applied in the field of sludge treatment methods and systems, can solve the problems of high oil content of residues and incomplete sludge separation, and achieve the effects of reducing water content, facilitating sludge separation and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

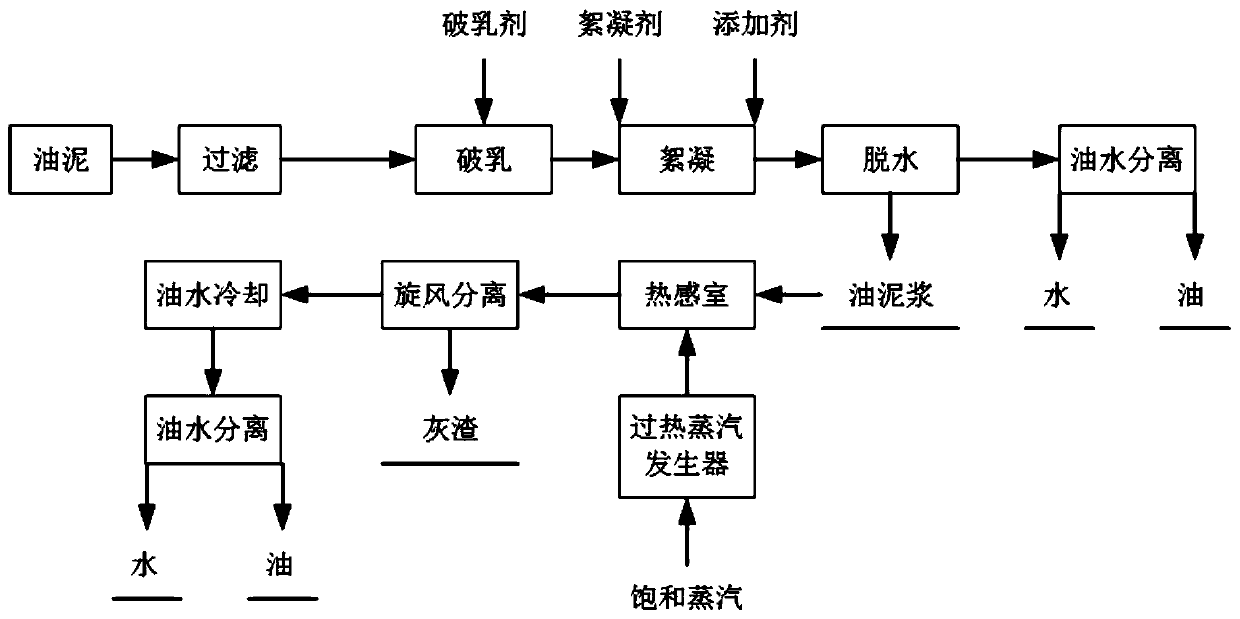

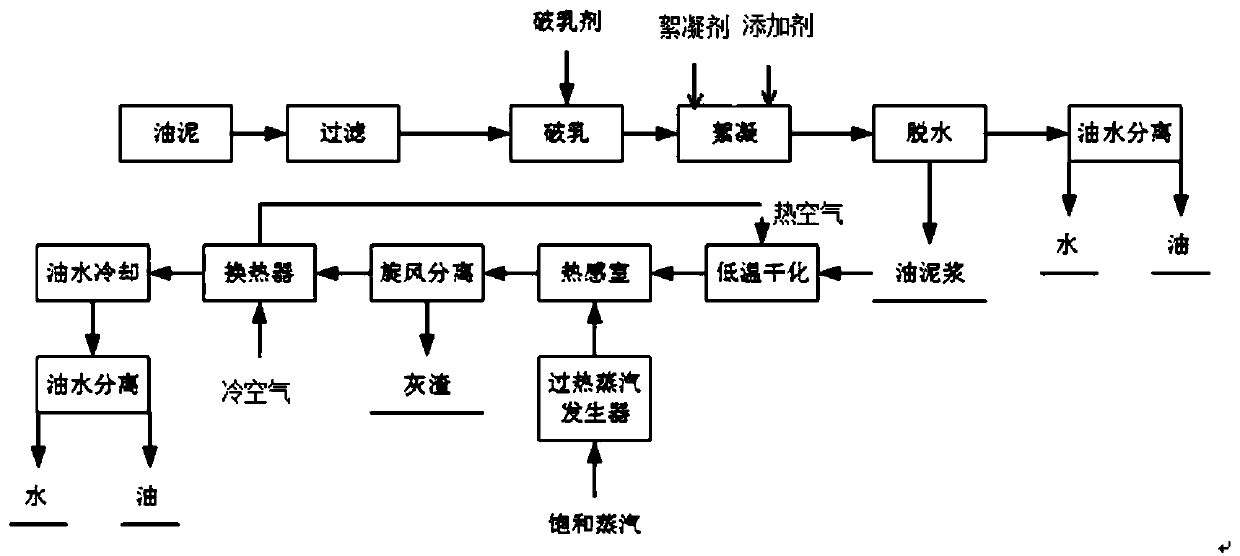

[0072] Such as image 3 As shown, this embodiment provides a sludge treatment system, including a screening device 1, a demulsification device 2, a flocculation device 3, a dehydration device 4, a thermal device 5, and a cyclone separation device connected in sequence through a sludge conveying pipeline 6. Cooling oil-water separation device 7; wherein, the demulsification device 2 is also provided with a demulsifier feed port, the flocculation device 3 is also provided with an additive feed port, and the dehydration device 4 is also provided with a waste water discharge port, The thermal sensing device 5 is also provided with a superheated steam inlet.

[0073] In the present invention, the sludge is processed sequentially through the screening device 1, the demulsification device 2, the flocculation device 3, the dehydration device 4, the thermal device 5, the cyclone separation device 6, and the cooling oil-water separation device 7, which can effectively solve the problem ...

Embodiment 2

[0094] This embodiment provides a method for treating oily sludge, wherein the oily sludge is oily sludge after sewage treatment in an oil refinery, with a water content of 95%, an oil content of 3%, and a solid content of 2%.

[0095] Including the following steps:

[0096] 1) Add demulsifier dodecyl sulfonic acid at 0.05% by weight of sludge to the sludge, heat to 50°C and stir to make it react fully and let it stand for 20 minutes, then add flocculant PAM at 0.02% by weight of sludge and 5% by weight of sludge The coke powder, continue to stir, make it stand still 2h again after fully reacting, obtain the oil sludge after the pretreatment;

[0097] 2) Transporting the pretreated oil sludge obtained in step 1) to a screw stacker for dehydration treatment to obtain an oil-water mixture and dehydrated oil sludge, wherein the dehydrated oil sludge has a water content of 80%;

[0098] 3) Pass the saturated steam through the superheated steam generator (superheated steam generat...

Embodiment 3

[0102] This embodiment provides a method for treating oil sludge, wherein the oil sludge is tank bottom sludge of an oil refinery, with a water content of 90%, an oil content of 8%, and a solid content of 2%.

[0103] Including the following steps:

[0104] 1) Add demulsifier triethanolamine oleate at 0.01% by weight of sludge to the sludge, heat to 40°C and stir to allow it to fully react and then let it stand for 20 minutes, then add flocculant polyaluminum chloride at 0.02% by weight of sludge and the weight of sludge 1% sawdust, continue to stir, let it fully react and let it stand for 1.5h again to get the pretreated oil sludge;

[0105] 2) transporting the pretreated oil sludge obtained in step 1) to a screw stacker for dehydration treatment to obtain an oil-water mixture and dehydrated oil sludge, wherein the moisture content of the dehydrated oil sludge is 60%;

[0106] 3) Pass the saturated steam through the superheated steam generator (superheated steam generator 9)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com