Treatment method and treatment system for zero discharge and fractional crystallization of concentrated brine

A technology of crystallization treatment and concentrated brine, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of difficult treatment of salty sewage, large consumption of fresh water, and suspended solids High concentration and other problems, to achieve the effect of reducing scale and operating costs, low investment and operating costs, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

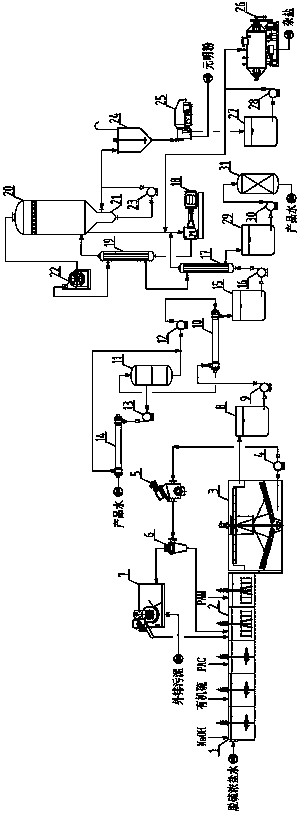

[0041] Such as figure 1 As shown, the treatment system of the present invention includes a reaction tank 1, a flocculation tank 2, a sedimentation tank 3, a high shear machine 5, a cyclone separator 6, a magnetic separator 7, a concentrated brine tank 8, a forward osmosis device 10, and recovery of a draw solution Device 11, reverse osmosis device 14, high concentrated brine tank 15, preheater 17, crystallization circulation pump 18, crystallization heater 19, crystallization reactor 20, elutriation column 21, steam compressor 22, salt pump 23, booster Thickener 24, centrifuge 25, dryer 26, condensed water tank 29 and resin ion exchange device 31.

[0042] Reaction tank 1 is divided into three grids connected in sequence, respectively provided with sodium hydroxide, organic sulfur and PAC (polyaluminum chloride) feeding ports, and equipped with agitator, flocculation tank 2 is divided into two grids connected in sequence, respectively There are magnetic seeds and PAM (polyacr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com