Ultra low density aerogel material, and preparation method and applications thereof

An ultra-low density, aerogel technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as high cost, difficulty in size control, and no reports on the application of large-scale materials, and achieve high Effects of Strength and Flexibility, Significant Application Prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

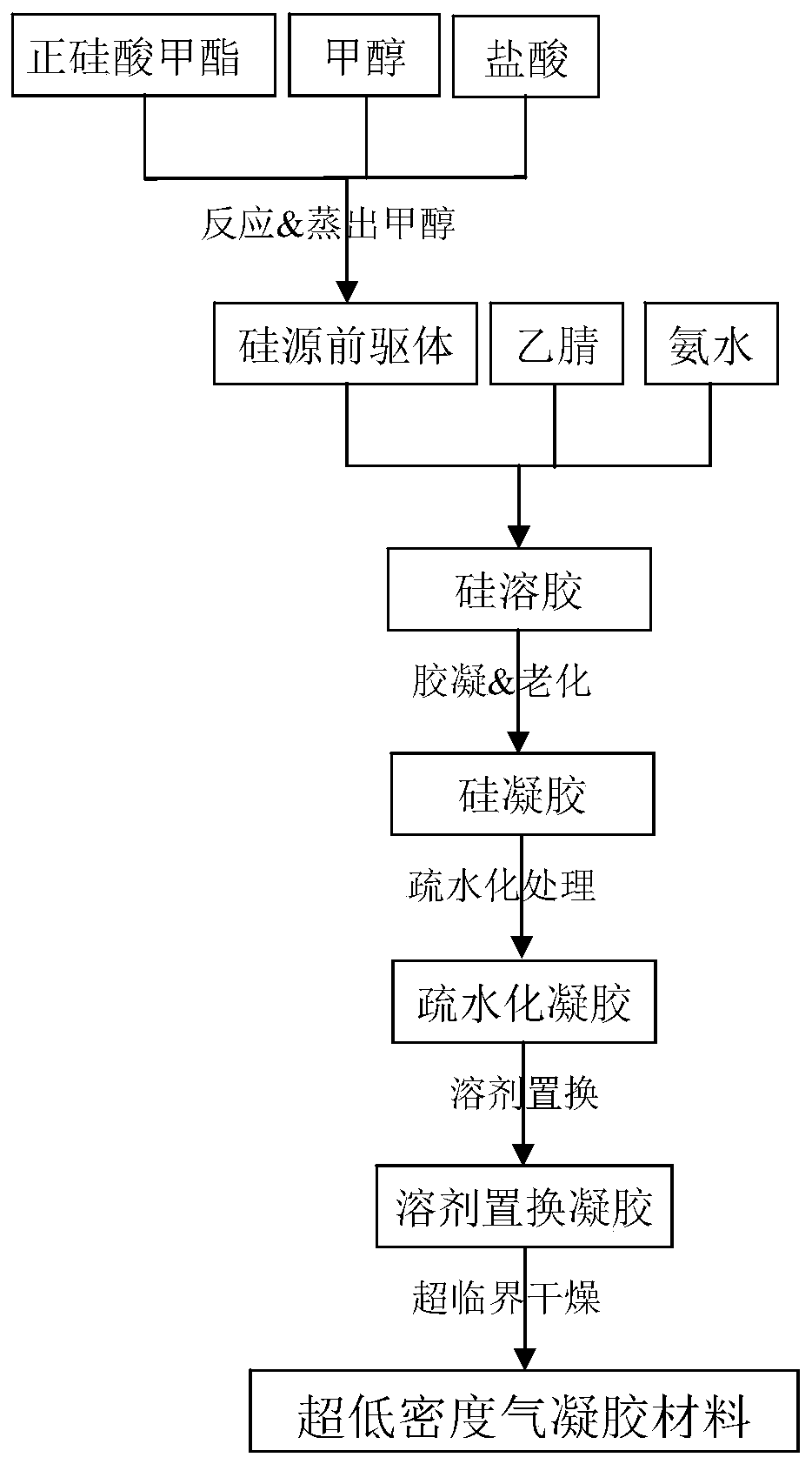

[0020] The present invention provides a kind of preparation method of ultra-low density airgel material in the first aspect, described method comprises the steps:

[0021] (1) Preparation of the sol precursor: add methyl orthosilicate, methanol and hydrochloric acid and mix together for reaction, then distill off the methanol, then add acetonitrile to obtain the sol precursor;

[0022] (2) Preparation of silica sol: mix the sol precursor with ammonia water, then add acetonitrile to prepare silica sol;

[0023] (3) Gelling and aging: gelling and aging the silica sol in turn to obtain a wet gel material;

[0024] (4) Moisture-proof treatment: using a hydrophobic agent to perform hydrophobic treatment on the wet gel material to obtain a hydrophobized gel material;

[0025] (5) Solvent replacement: performing solvent replacement on the hydrophobized gel material to obtain a solvent replacement gel;

[0026] (6) Supercritical drying: the solvent-displaced gel is put into a drying...

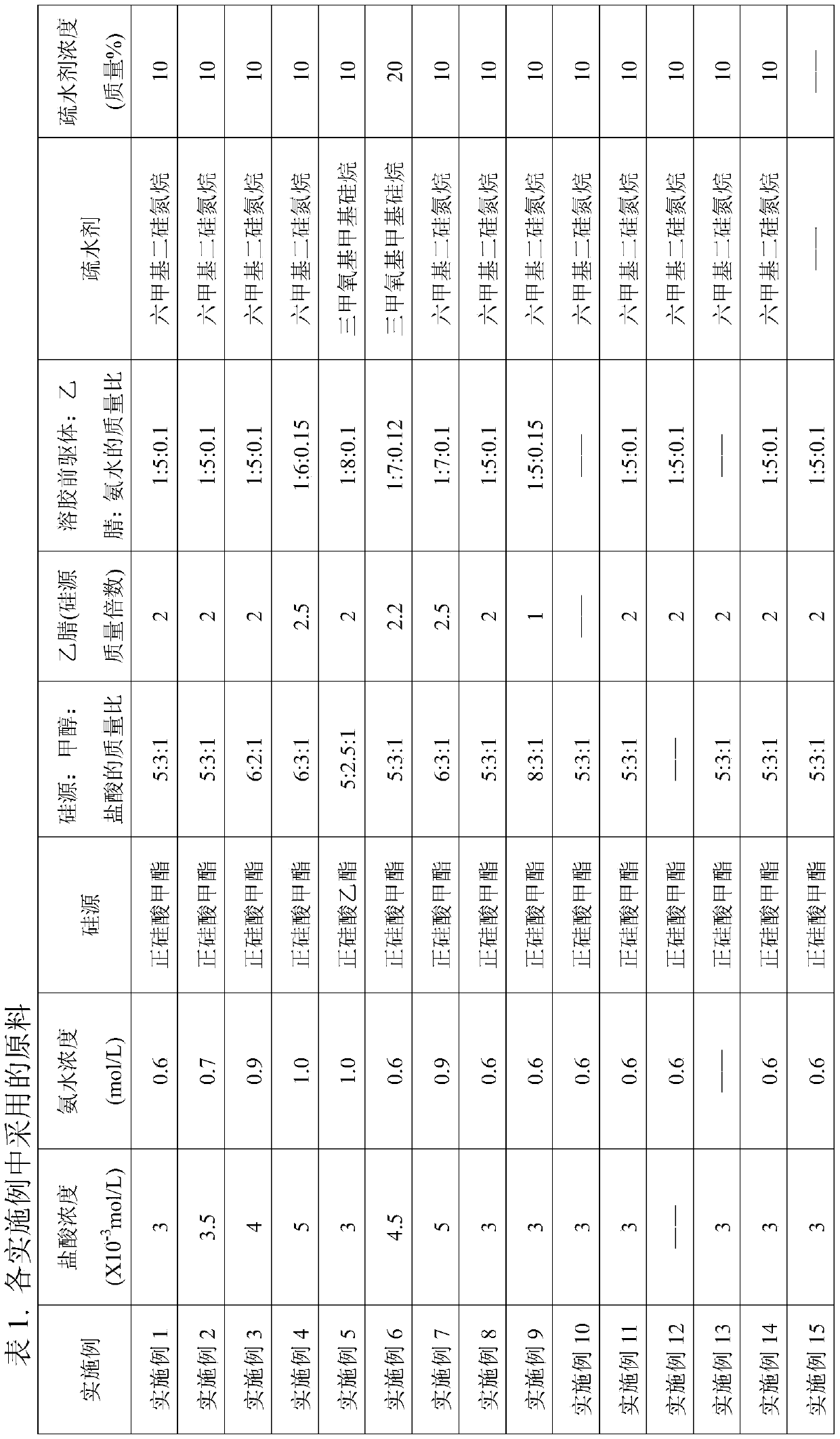

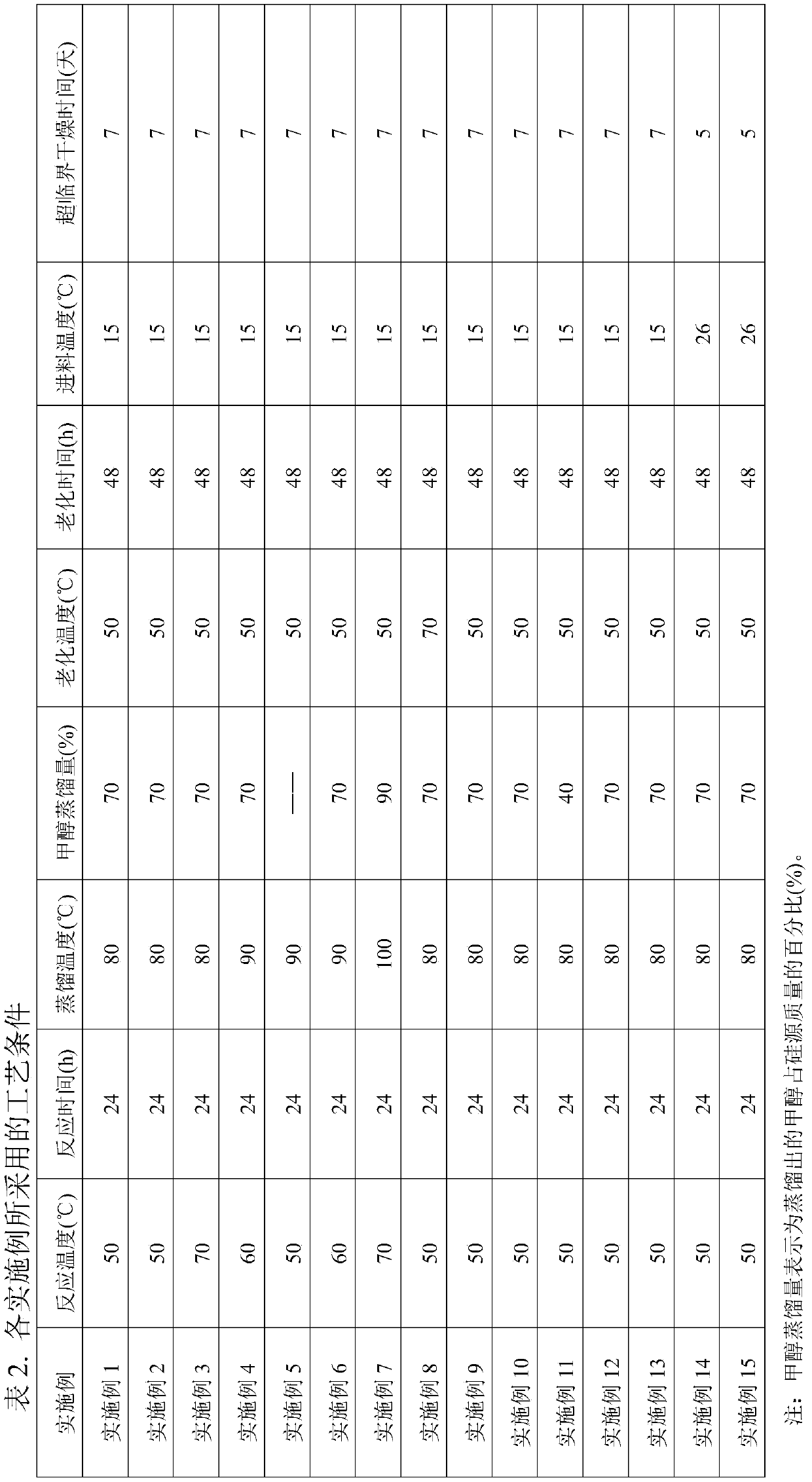

Embodiment 1

[0057] First prepare a concentration of 3*10 -3 mol / L hydrochloric acid, 0.6mol / L ammonia solution. The mass ratio of methyl orthosilicate:methanol:hydrochloric acid is 5:3:1, and the reaction temperature is 50°C in an oil bath for 24 hours; afterward, distillation is carried out at a distillation temperature of 80°C, and 70% of the silicon source is distilled. After mass % of methanol solvent, add acetonitrile solvent whose mass is twice as much as methyl orthosilicate, and stir for 10 minutes to obtain the sol precursor; then mix the glue according to the mass ratio of sol precursor: acetonitrile: ammonia water is 1:5:0.1 , and stirred for 20 minutes to obtain a silica sol; pour the silica sol into a mold and place it at room temperature for 48 hours, then continue to age it at 50°C for 48 hours, remove the mold after aging, and add 10% by mass of hexamethyldisilazol Azane was put into ethanol solvent for hydrophobization treatment; supercritical CO was carried out after tw...

Embodiment 2

[0059] First prepare a concentration of 3.5*10 -3 mol / L hydrochloric acid, 0.7mol / L ammonia solution. The mass ratio of methyl orthosilicate:methanol:hydrochloric acid is 5:3:1, and the reaction temperature is 50°C in an oil bath for 24 hours; afterward, distillation is carried out at a distillation temperature of 80°C, and 70% of the silicon source is distilled. After mass % of methanol solvent, add acetonitrile solvent whose mass is twice as much as methyl orthosilicate, and stir for 10 minutes to obtain the sol precursor; then mix the glue according to the mass ratio of sol precursor: acetonitrile: ammonia water is 1:5:0.1 , stirred for 20 minutes to obtain silica sol; pour the silica sol into the mold; after standing at room temperature for 48 hours, continue to age at 50°C for 48 hours, remove the mold after aging, and add 10% by mass of hexamethyl di Silazane was placed in ethanol solvent for hydrophobization treatment; supercritical CO 2 Drying, feeding at a low tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com