Intelligent heating control method

A control method and intelligent heating technology, applied in the field of control, can solve the problems of unqualified sheet quality, low reliability and stability of extruder, and inability to judge the health status of screw in time, so as to ensure quality and improve stability and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

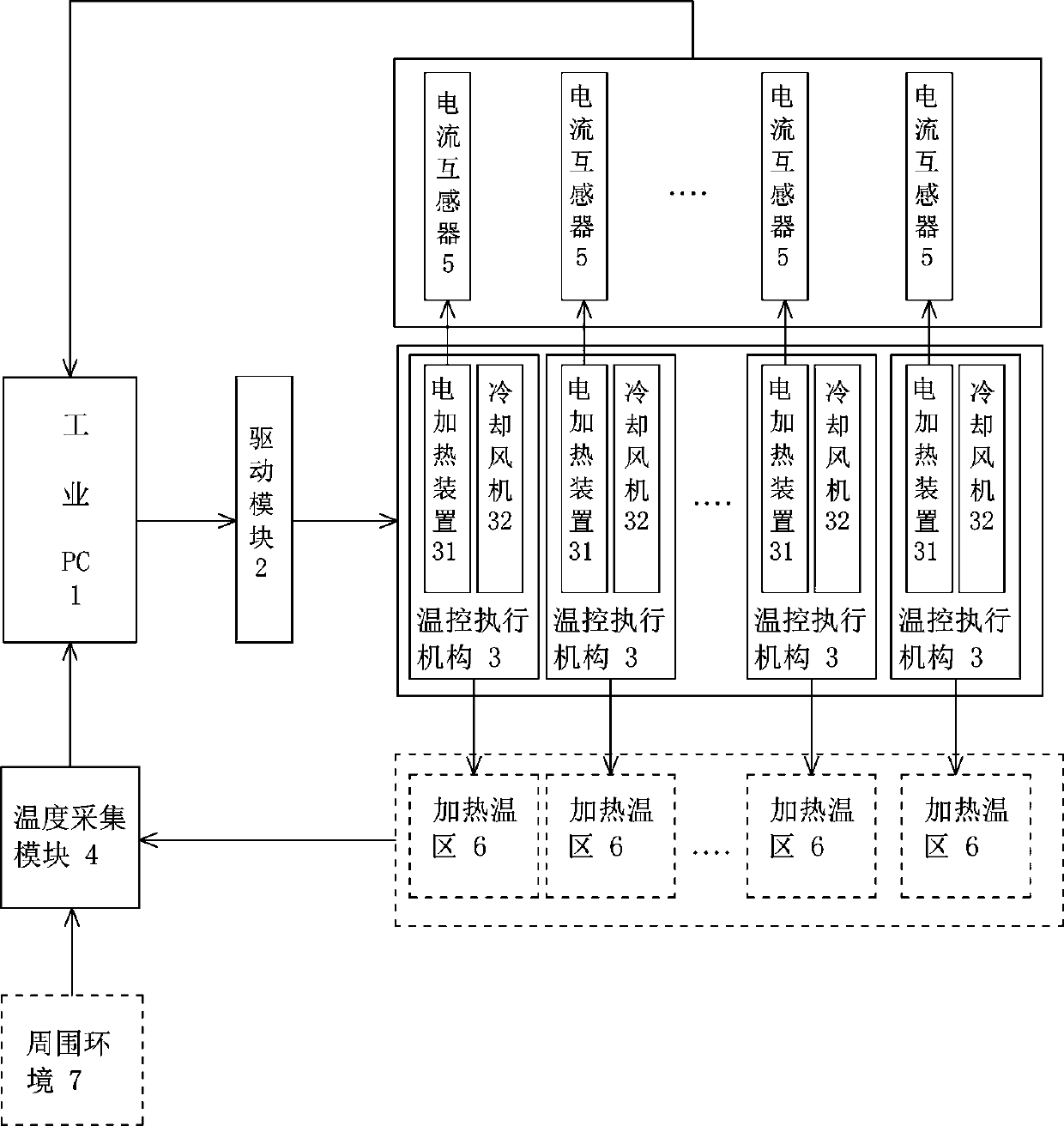

[0025] Such as figure 1 As shown, this intelligent heating control method includes collecting the ambient temperature value of the surrounding environment 7 through the temperature acquisition module 4, the heating temperature value of each heating temperature zone 6, and the first melt temperature value when the melt enters each heating temperature zone 6 and the second melt temperature value when leaving the heating temperature zone 6 and fed back to the industrial PC1, the industrial PC1 collects the ambient temperature value of the surrounding environment 7, the heating temperature value of each heating temperature zone 6, and each first melt temperature value and each second melt temperature value for statistics and analysis, the industrial PC1 controls each temperature control actuator 3 to heat or dissipate heat to the corresponding heating temperature zone 6 through the drive module 2; the intelligent heating control method also uses each current mutual inductance The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com