Wall-type combustion boiler mixed coal blending combustion optimization method

An optimization method and boiler technology, applied in the direction of combustion methods, burners for burning powder fuel, burners, etc., can solve the problems of high-temperature corrosion emission concentration of slagging on the left and right side walls, difficulty in igniting and burning low-volatile coal, etc., to avoid Effects of slagging and high-temperature corrosion, improvement of ignition and combustion stability, and increase of oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

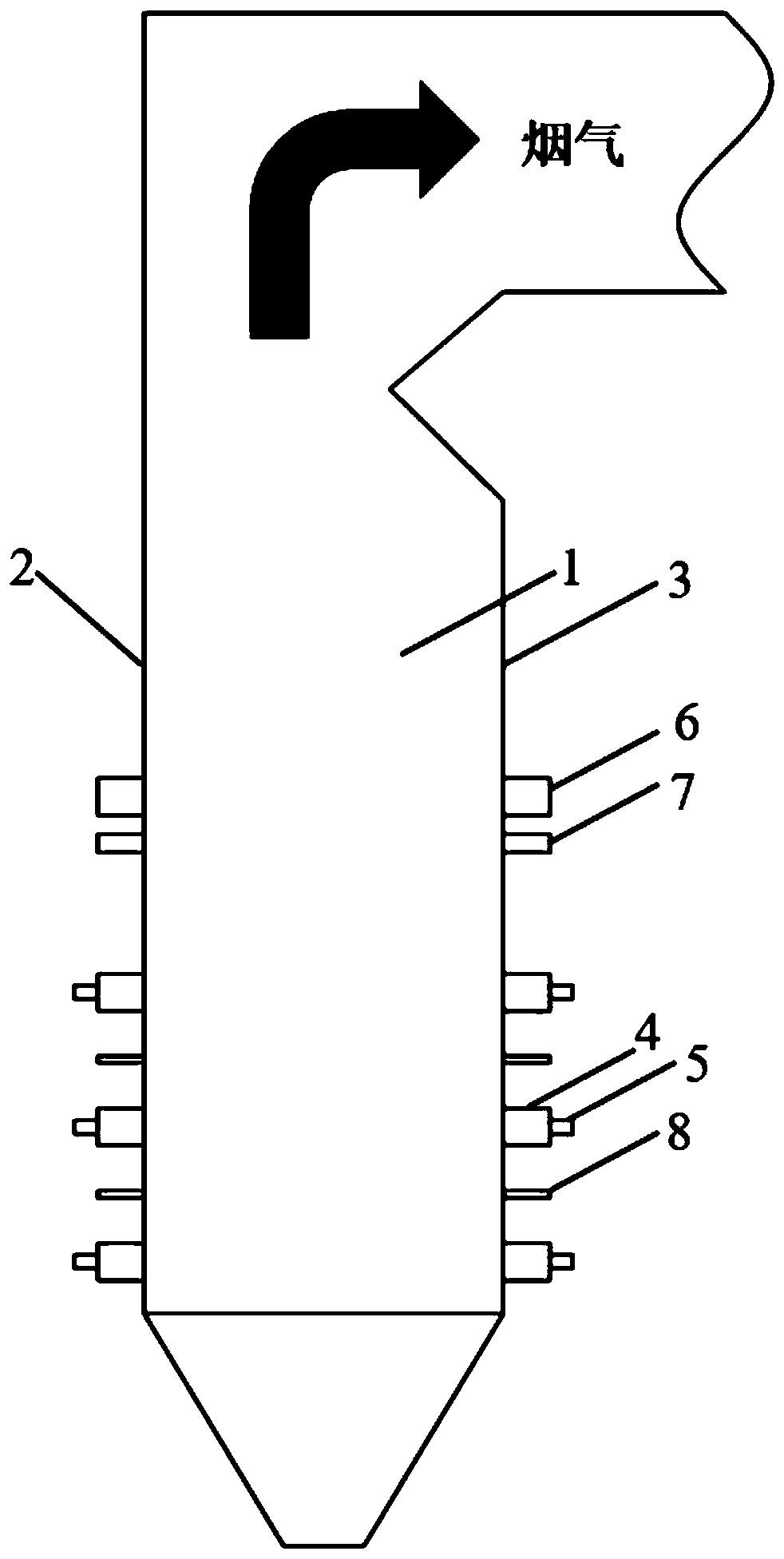

[0031] like figure 1 and figure 2 As shown, this embodiment provides a method for optimizing the coal-mixed combustion of a wall-fired boiler, which includes dividing the coal used for combustion in the wall-fired boiler into two types: A coal type and B coal type; the wall-fired boiler includes a boiler furnace 1. Boiler front wall 2. Boiler back wall 3. Several burners 4. Several primary air ducts 5. Several burnout air nozzles 6. Several side burnout air nozzles 7. Several wall-mounted air nozzles 8 , The burner 4 is arranged on the boiler front wall 2 and the boiler rear wall 3 .

[0032] The burner 4 includes a burner A and a burner B. The burner A burns pulverized coal of the A coal type, and the B burner burns the pulverized coal of the B coal type. Air duct and B primary air duct, A primary air duct only transports coal type A, B primary air duct only transports B coal type, A burner is connected with the output end of A primary air duct one by one, and B burner It...

Embodiment 2

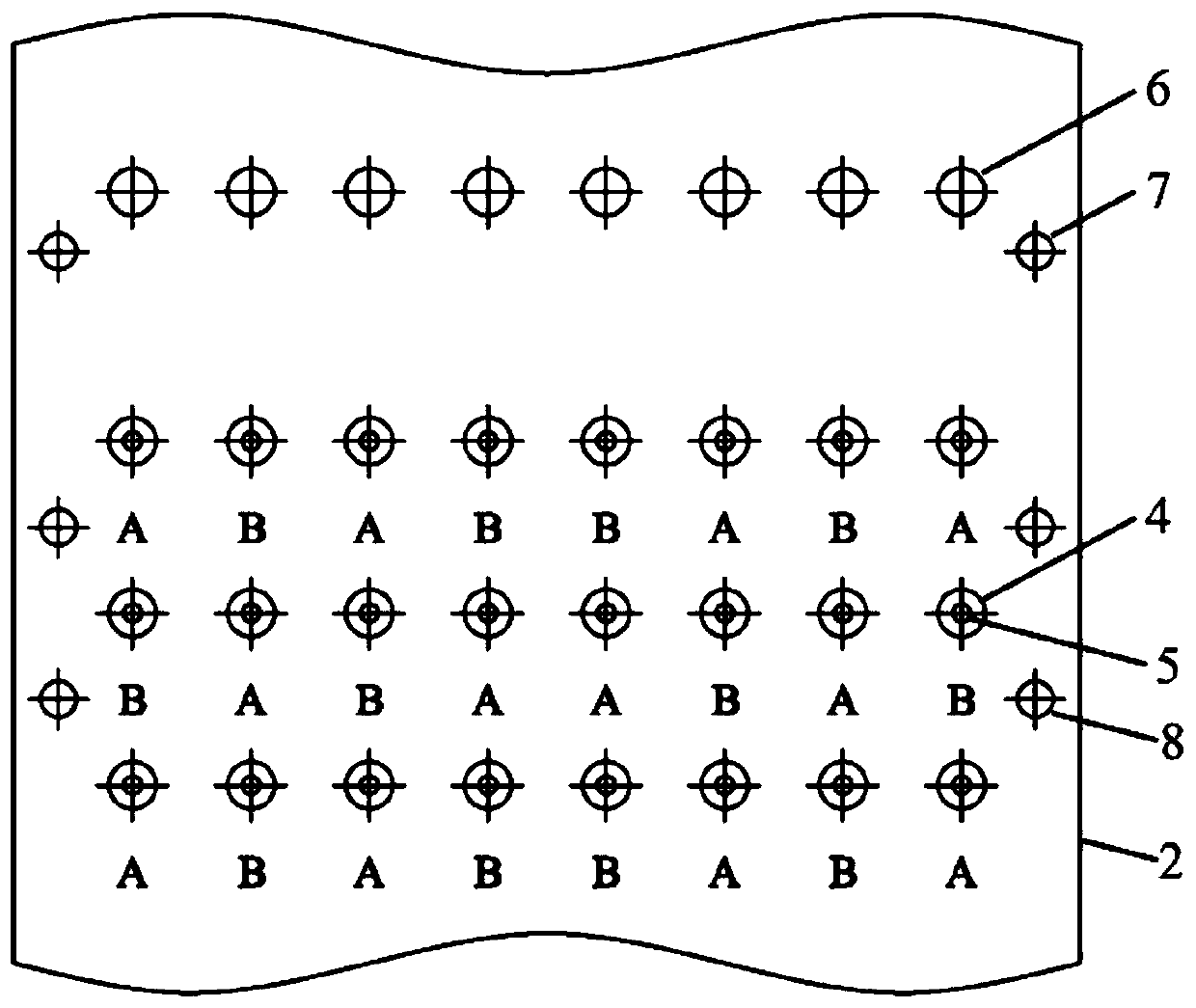

[0039] On the basis of Example 1, such as image 3 As shown, for a 1000MW wall-type hedging pulverized coal combustion boiler, three layers of burners 4 are arranged on the boiler front wall 2 and boiler rear wall 3 respectively, and eight burners 4 are arranged on each layer, and the total number of burners 4 is 48; The wall air nozzle 8 is arranged at the center of the adjacent two-layer burner 4 along the height direction of the boiler front wall 2 and the boiler rear wall 3, and is at the same position as the side burn-out air nozzle 7 in the width direction of the boiler front wall 2 and the boiler rear wall 3 , 8 wall-adhering air spouts 8 are arranged in total, and 4 wall-adhering air spouts 8 are respectively arranged on the boiler front wall 2 and the boiler rear wall 3.

[0040] The lowest layer burners 4 are arranged as shown in the figure, and the types of coal fed in order from left to right are A, B, A, B, B, A, B, A; the middle layer burners 4 are arranged as sh...

Embodiment 3

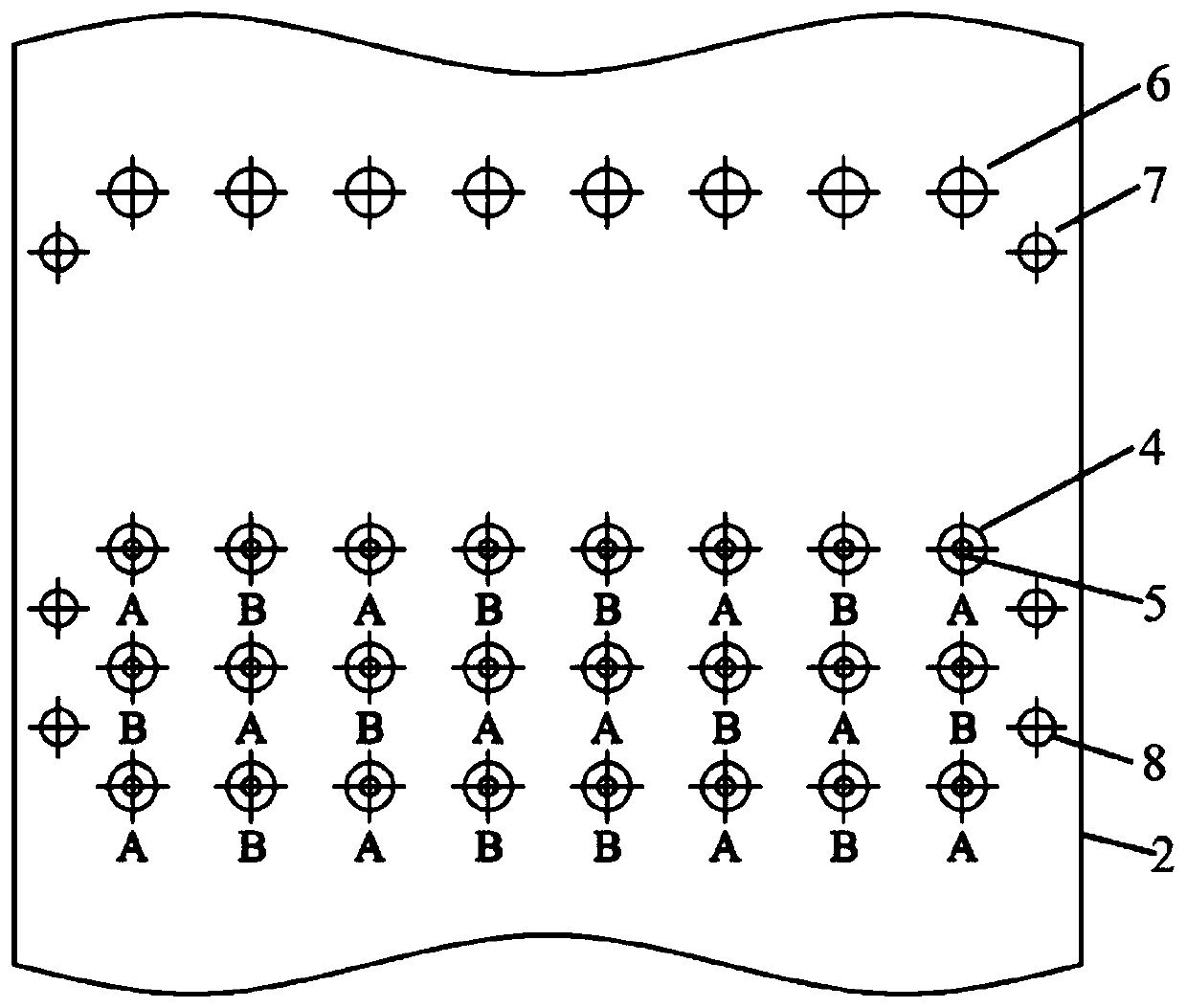

[0042] On the basis of Example 1, such as Figure 4 As shown, for a wall-type hedging pulverized coal fired boiler with a capacity of 1000MW and above, four layers of burners 4 are arranged on the front wall 2 of the boiler and the rear wall 3 of the boiler, each layer has eight burners 4, and the total number of burners 4 is 64 only. The wall-attached air nozzle 8 is arranged at the center of the adjacent two-layer burner 4 along the height direction of the boiler front wall 2 and the boiler rear wall 3, and at the position of the side burn-out air nozzle 7 in the width direction of the boiler front wall 2 and the boiler rear wall 3 Similarly, a total of 12 wall-mounted air nozzles 8 are arranged, and 6 wall-mounted air nozzles 8 are respectively arranged on the boiler front wall 2 and the boiler rear wall 3 .

[0043] The burners 4 in the lowest layer are arranged as shown in the figure, and the types of coal fed in sequence from left to right are A, B, A, B, B, A, B, A; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com