A pick-up method for metal micro-components based on electrochemical deposition

A technology for depositing metal and micro-components, which is applied in the direction of manufacturing tools, chucks, manipulators, etc., can solve the problems of picking up damage to metal micro-components, etc., and achieves the effects of low preparation cost, short preparation period and improved success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

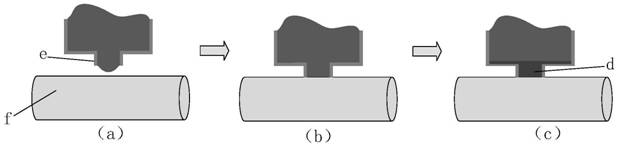

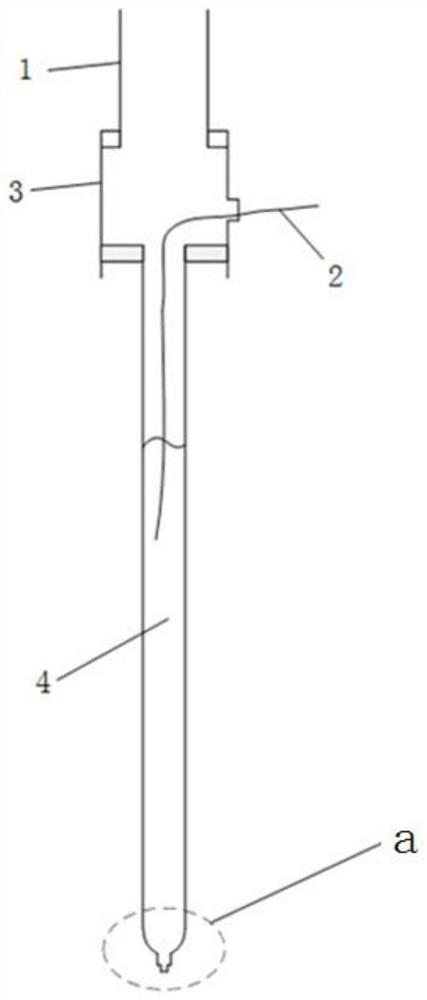

[0056] combine figure 1 with figure 2 Note that the metal micro-component in this embodiment is a micro-copper wire, the length of the micro-copper wire is 400 μm, and the radius is 20 μm. The electrolyte used in this embodiment has a concentration of 200mol / m 3 copper sulfate solution;

[0057] In this embodiment, the pick-up method of metal micro-components based on electrochemical deposition is carried out according to the following steps:

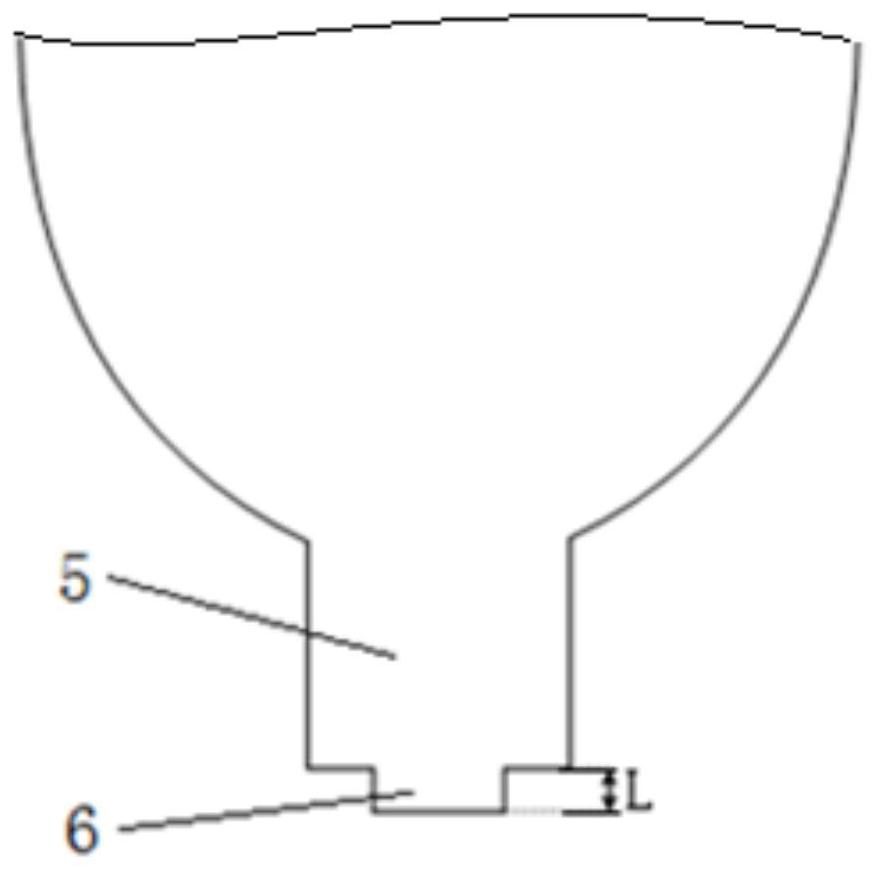

[0058] Step 1: Calculate the minimum nozzle radius r that can successfully pick up the required pipette according to the stress conditions of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com