Covering agent for preventing tundish from being melted and damaged and application

A covering agent and tundish technology, which is applied in the application field of continuous casting auxiliary materials, can solve the problems of inability to prevent the erosion of the tundish coating and insufficient adsorption capacity, so as to reduce the abnormal opening and casting, solve the problem of melting damage, and stabilize the continuous casting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

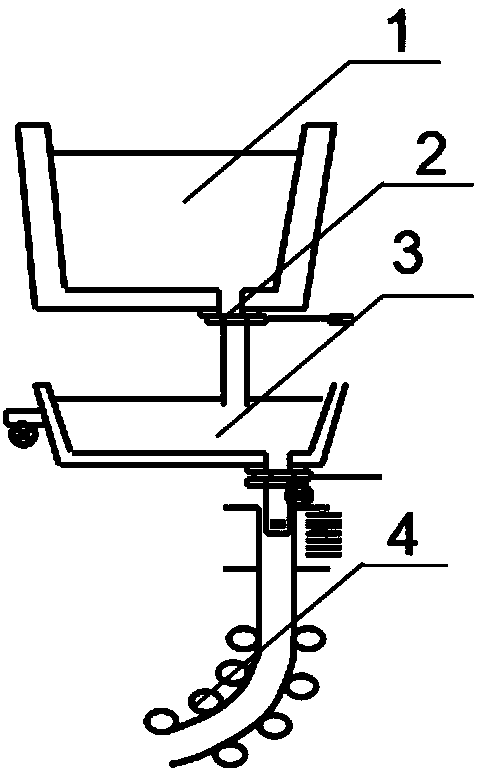

Image

Examples

Embodiment 1

[0036] The covering agent for preventing tundish melt damage is produced according to the technical plan and the important components of the ingredients in the technical description.

[0037] 1. Prepare the premelt. According to 58% CaO, 22% Al 2 o 3 , 10% MgO, 8% SiO 2 And 2% C to carry out the proportioning of composition. Among them, CaO and Al 2 o 3 Wollastonite can be used as an incoming material source.

[0038] 2. Prepare magnesia. Using magnesite, the sintering temperature is controlled at 700-950 degrees, and the main component of MgO with a purity of more than 95% is prepared, which is used as the adsorbate of the premelted material in the tundish. The mixing mass ratio of premelt and magnesia is 5:1.

[0039] 3. Mechanically mix the premelted material prepared above with magnesia to form a tundish covering agent for preventing erosion of the tundish.

[0040] Before use, the depth of melting damage in the tundish can reach 20mm-30mm. After the implementatio...

Embodiment 2

[0042] 1. Prepare the premelt. According to 55% CaO, 24% Al 2 o 3 , 11% MgO, and 7.5% SiO 2 , 2.5% C for the proportioning of ingredients. Among them, CaO and Al2O3 can use wollastonite as the source of incoming materials.

[0043] 2. Prepare magnesia. Using magnesite, the sintering temperature is controlled at 700-950 degrees, and the main component of MgO with a purity of more than 95% is prepared, which is used as the adsorbate of the premelted material in the tundish. The mixing mass ratio of premelt and magnesia is 6:1.

[0044] 3. Mechanically mix the premelted material prepared above with magnesia to form a tundish covering agent for preventing erosion of the tundish.

[0045]Before use, the depth of melting damage in the tundish can reach 20mm-30mm. After the implementation, the depth is basically within 2mm, which basically solves the problem of melting damage.

Embodiment 3

[0047] 1. Prepare the premelt. According to 52.5% CaO, 23% Al 2 o 3 , 11% MgO, and 10% SiO 2 , 3.5% of C for the ratio of ingredients. Among them, CaO and Al2O3 can use wollastonite as the source of incoming materials.

[0048] 2. Prepare magnesia. Using magnesite, the sintering temperature is controlled at 700-950 degrees, and the main component of MgO with a purity of more than 95% is prepared, which is used as the adsorbate of the premelted material in the tundish. The mixing mass ratio of premelt and magnesia is 3:1.

[0049] 3. Mechanically mix the premelted material prepared above with magnesia to form a tundish covering agent for preventing erosion of the tundish.

[0050] Before use, the depth of melting damage in the tundish can reach 20mm-30mm. After the implementation, the depth is basically within 2mm, which basically solves the problem of melting damage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com