Magnetic ball and production method thereof

A production method, the technology of magnetic balls, applied in the field of magnetic balls, can solve the problems of high cost, large waste of consumption rate, high price of NdFeB, etc., and achieve the effect of cost saving and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

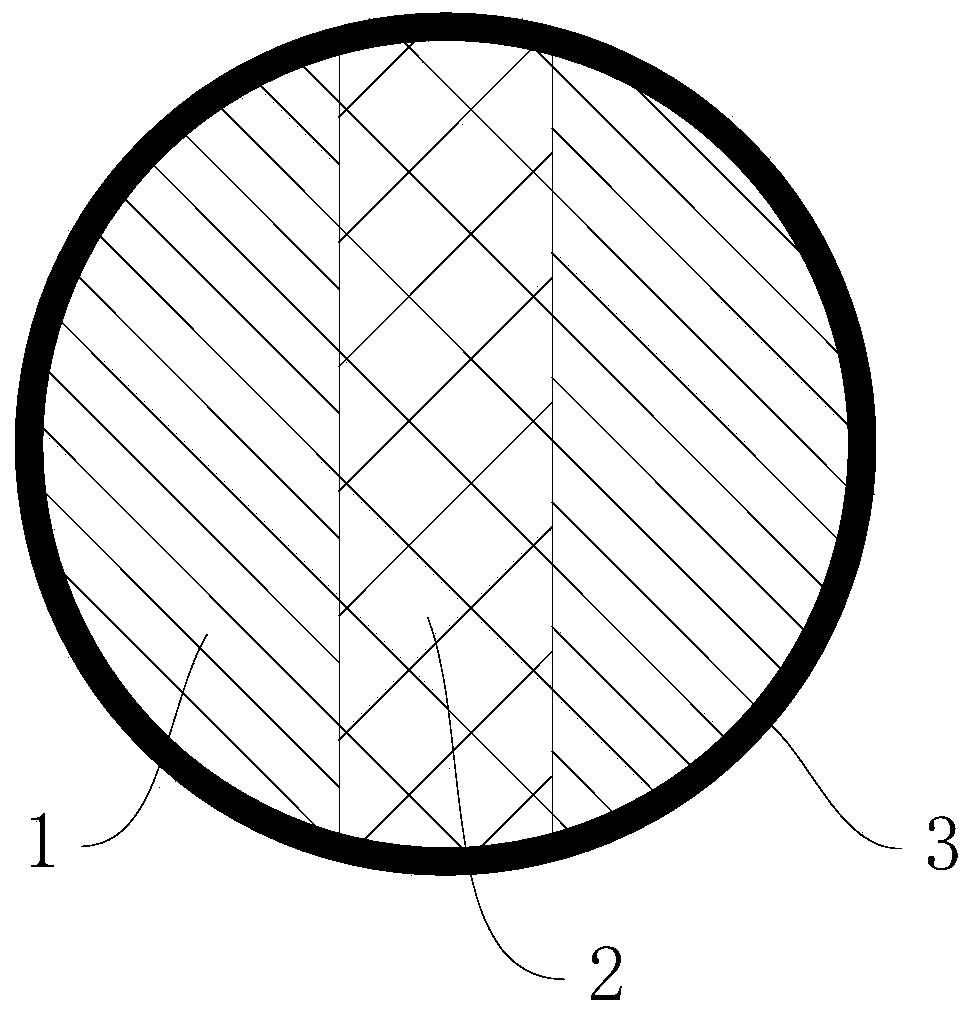

[0035] A magnetic ball, see attached figure 1 , including a spherical magnetic ball body 1 and a magnetic core 2 arranged inside, the magnetic core 2 passes through the center of the magnetic ball body 1, and the magnetic core 2 is made of NdFeB, and the magnetic ball body 1 is made of iron or other Made of magnetic material. In order to improve the service life of the magnetic ball, a layer of coating 3 is also electroplated on the surface of the magnetic ball. The coating 3 can be chromium, tweezers or other anti-oxidation materials, which not only improves the rust resistance of the magnetic ball, but also extends the magnetic core. 2 degaussing cycles.

[0036] The production method of above-mentioned magnetic force ball, in conjunction with attached figure 1 and 2 , similar to the general production method of steel balls, the ingredients before grinding the balls are usually called cubes or cylinders, and the magnetic embryos in Example 1 are cubes. Its production ste...

Embodiment 2

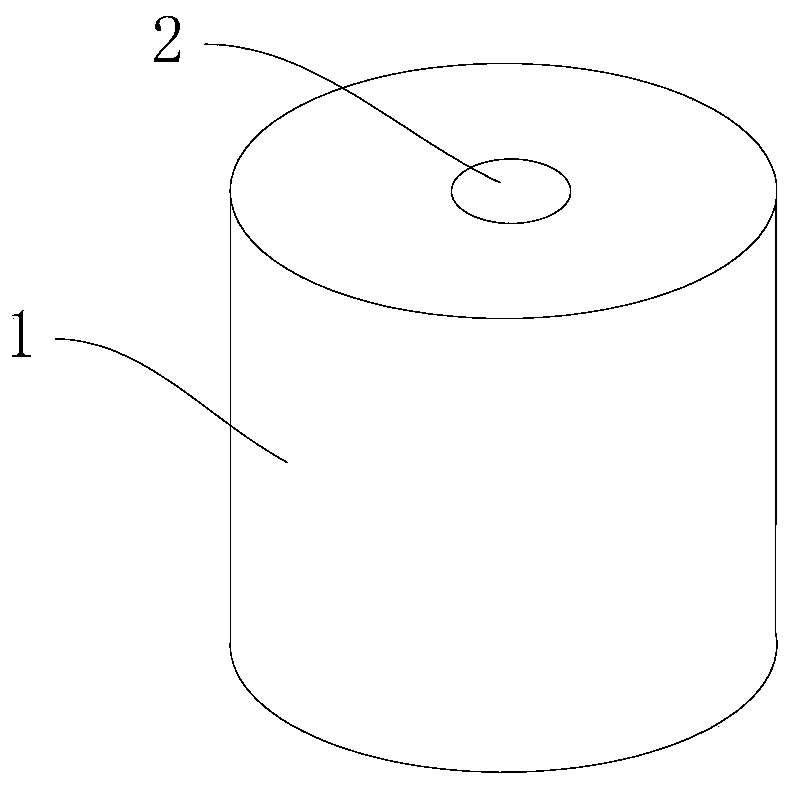

[0043] A kind of method of producing magnetic ball, see attached figure 1 and 3 , The difference from Example 1 is that the magnetic embryo is cylindrical. The differences in processing are:

[0044] S1, prepare materials, take some first blanks made of magnetically conductive materials and some second blanks made of NdFeB, the first blanks are cylindrical, and the length and diameter of the first blanks are greater than or equal to the one to be prepared. The diameter of the magnetic ball made; the length of the second blank is equal to the length of the first blank;

[0045] S2, pre-processing, drilling the first blank to form an installation hole for installing the second blank, the diameter of the installation hole is less than or equal to the diameter of the second blank, and the installation hole is the same as the axis of the first blank axis.

[0046] The rest of the steps are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com