Electric power pipe rack and anti-flooding wall co-building structure and construction method thereof

A technology of power pipe gallery and construction method, which is applied in the direction of basic structure engineering, underwater structures, dikes, etc., can solve the problems of high demolition costs, large project investment, large land area, etc., and improve construction safety and standards, safety The effect of high performance and reduced engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

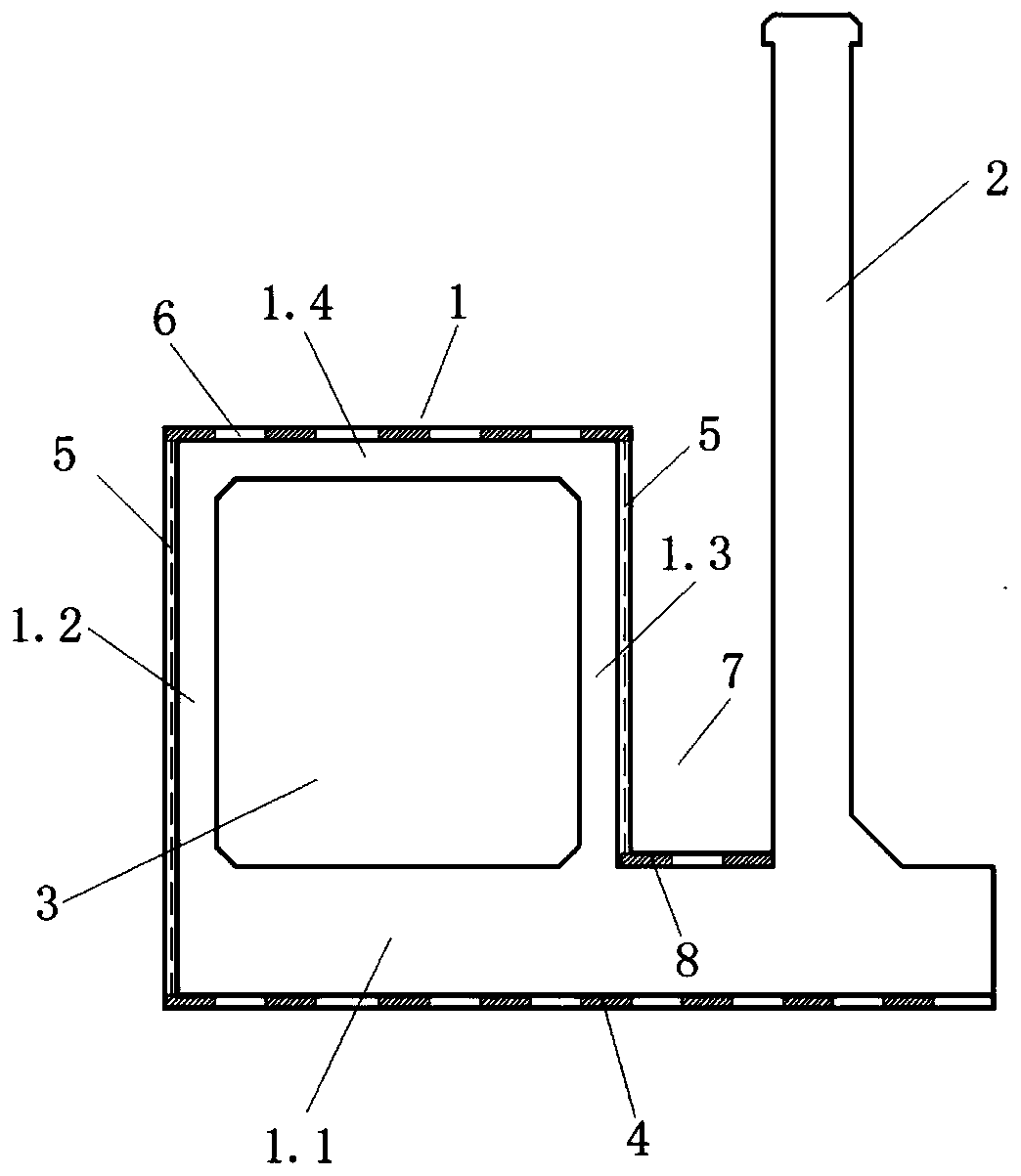

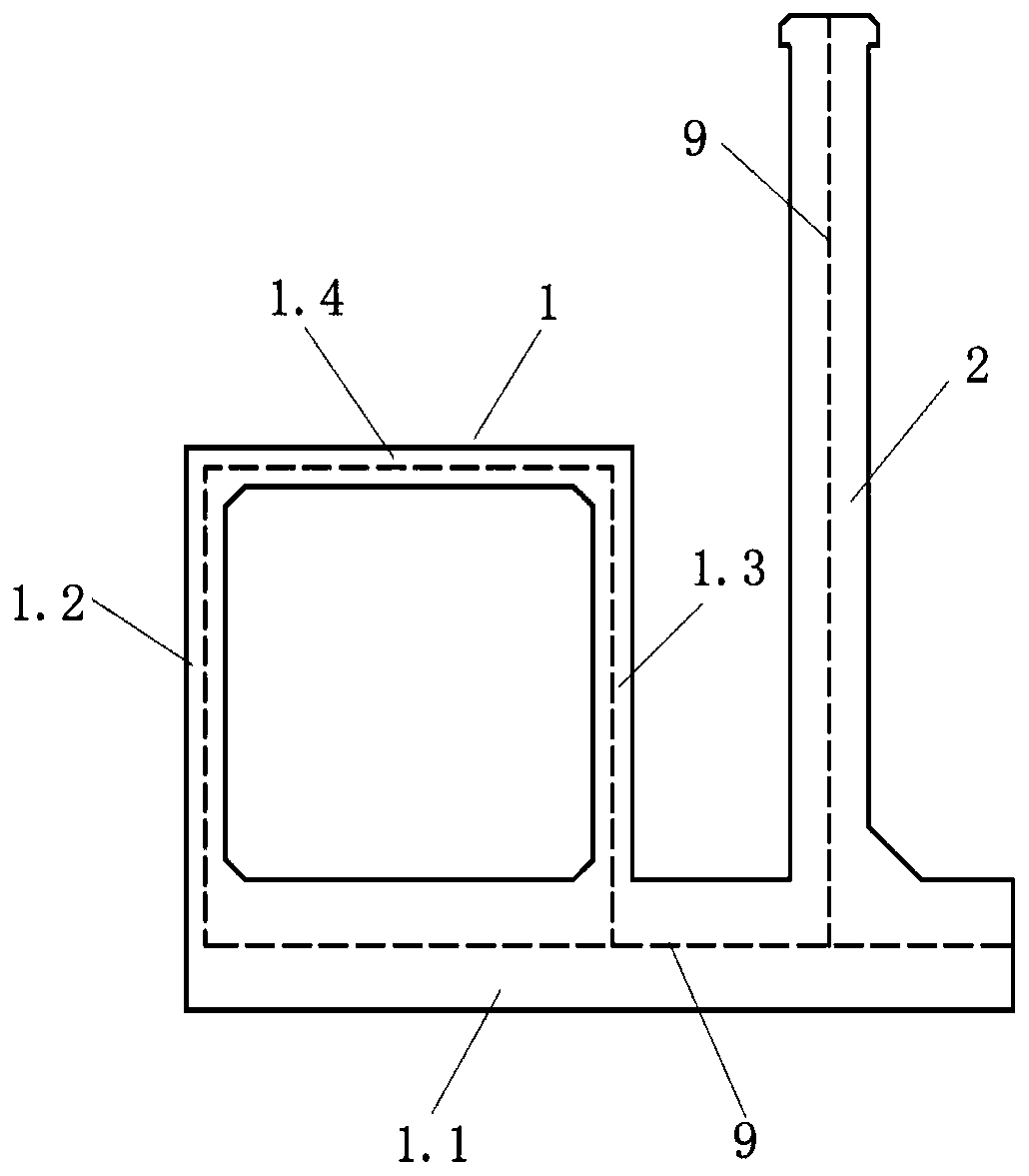

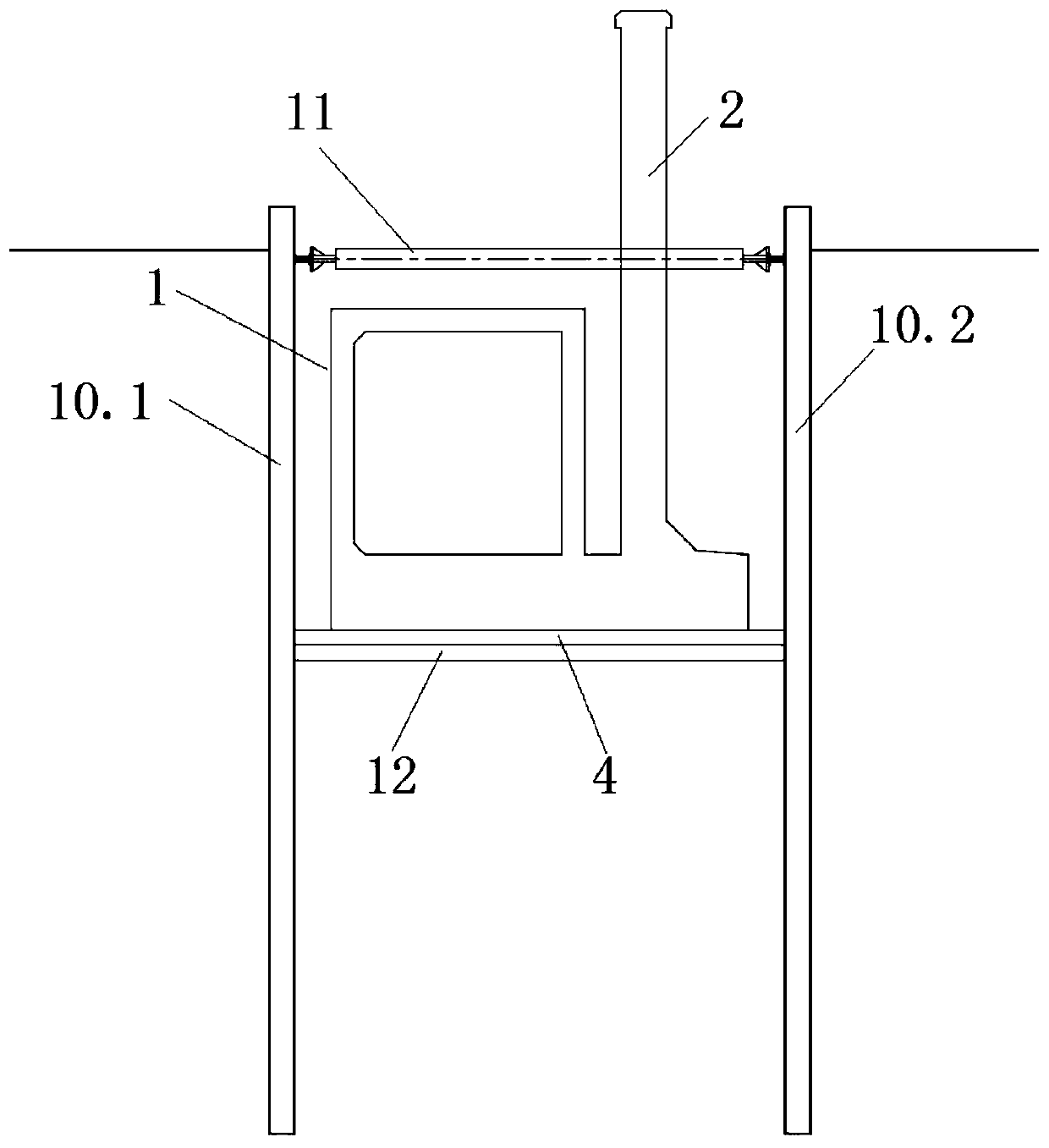

[0032] Such as figure 1 The shown co-construction structure of a power pipe gallery and a flood control wall designed by the present invention includes a power pipe gallery body 1 and a flood control wall 2. The power pipe gallery body 1 is a rectangular frame structure, including a bottom plate 1.1, a first Pipe gallery side wall 1.2, second pipe gallery side wall 1.3, and pipe gallery roof 1.4, the first pipe gallery side wall 1.2 is set on one side of the bottom plate 1.1 in the width direction, and the flood control wall 2 is set on the bottom plate 1.1 in the width direction On the other side, the second pipe gallery side wall 1.3 is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com