Method for constructing hierarchical-pore MOF (metal organic framework) by ligand selective retention

A technology of hierarchical pores and ligands, applied in the field of hierarchical porous MOFs, can solve the problems of poor stability of MOFs, and achieve significant catalytic effect, good acid-base stability, and enhanced Lewis acidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

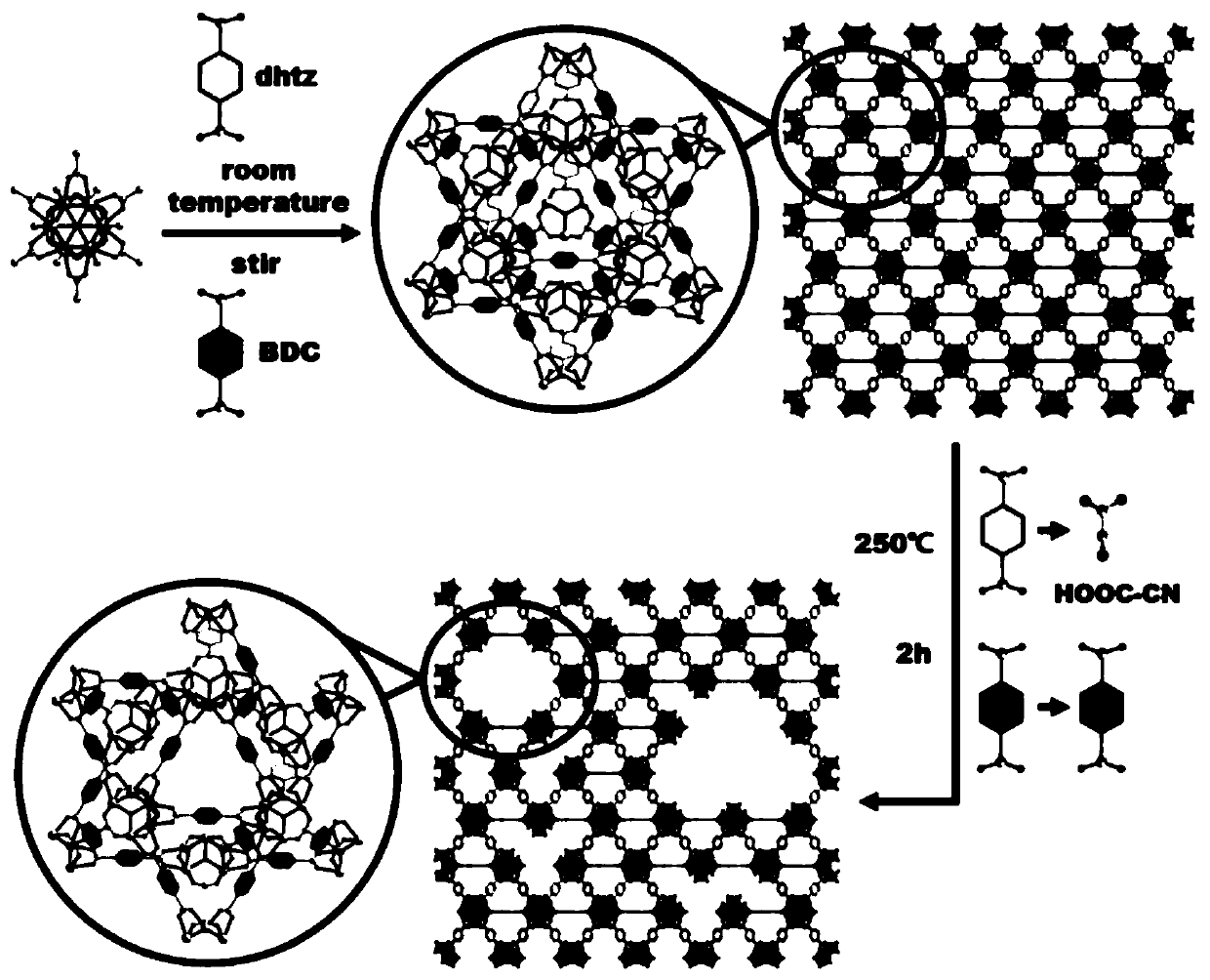

[0023] The present invention relates to the preparation of hierarchically porous UiO-66 by ligand selective retention method. For the specific process, please refer to the attached figure 1 . The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

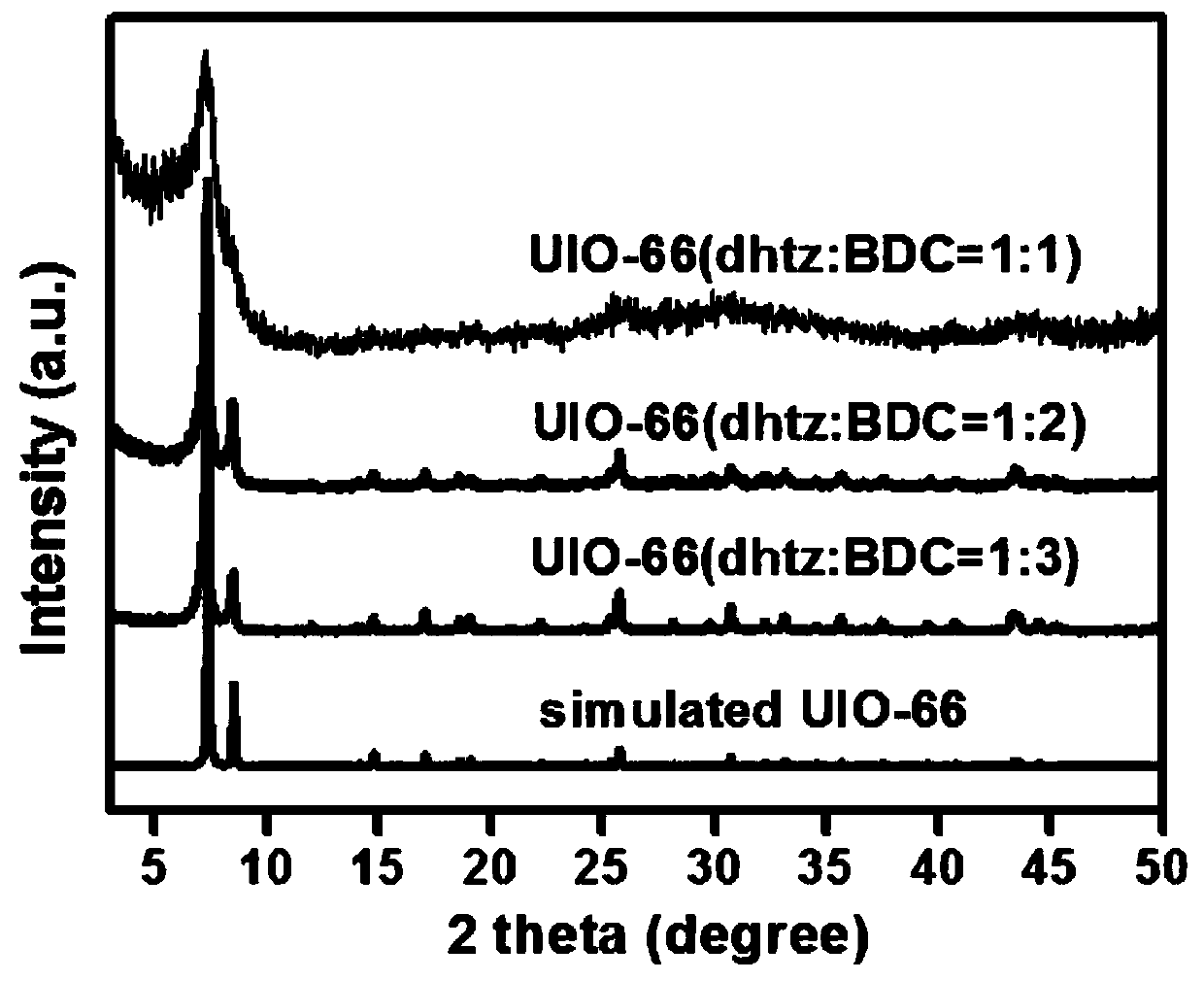

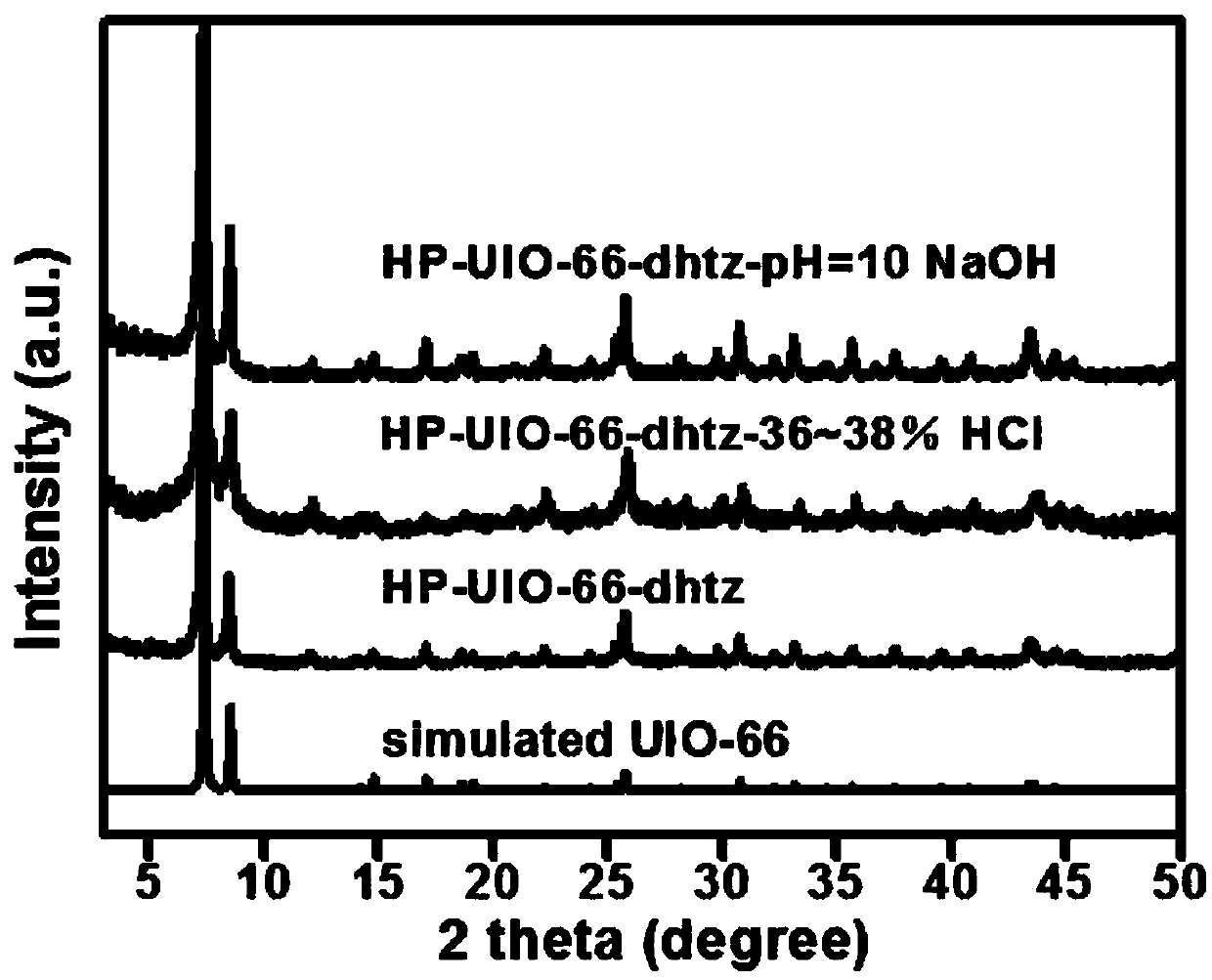

[0024] Preparation of HP-UiO-66-dhtz (BDC:dhtz=1:1): Take 4 mL of glacial acetic acid and 7 mL of DMF in a 20 mL glass bottle, and add 70 μL of zirconium n-propoxide into it. Stir evenly, put the glass vial in an oven at 130°C for two hours, and the solution turns from colorless to yellow. Weigh 36.5mg BDC and 36.5mg dhtz, add them to the above solution, put them into a horizontal shaker, and react at 240rpm, 25°C for 5-7 days until all the white powder in the bottle turns into yellow powder. Centrifuge and wash three times with ethanol. After drying the sample in N 2 Hierarchical UiO-66 was obtained by pyrolysis at 250℃ for 2h under atmosphere.

[0025] Preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com