Magnetic nano adsorbent for metallurgical wastewater and preparation method of magnetic nano adsorbent

A magnetic nano and adsorbent technology, applied in metallurgical wastewater treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc. The effect of increasing electronegativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the magnetic ferroferric oxide / nickel oxide modified sepiolite specifically comprises the following steps:

[0026] (1) Acid-activated sepiolite: add sepiolite to 5-10% nitric acid at a solid-to-liquid ratio of 0.06-0.1g / ml, and soak for 6-12 hours at 40-80°C. During this acid pickling process, H + Replace Mg in the sepiolite fiber layer 2+ and Al 3+ , to generate cation defect lattice, form a large amount of Si-OH, increase active sites, and at the same time incorporate nitrogen element, further increase electronegativity, improve the adsorption and chelation performance of magnetic nano adsorbents on metal cations and other soluble pollutants, After filtering, washing, drying, and crushing into 100-300μm particles, activated sepiolite is obtained;

[0027] (2) Preparation of magnetic iron ferric oxide / nickel oxide precursor: Dissolve ferric salt and divalent nickel salt in ethylene glycol according to the solid-to-liquid ratio of 0.1-0.3mg / ...

Embodiment 1

[0031] Example 1: Preparation of magnetic ferric oxide / nickel oxide modified sepiolite

[0032] (1) Acid-activated sepiolite: add sepiolite to 7.5% nitric acid at a solid-to-liquid ratio of 0.08g / ml, soak at 60°C for 10 hours, filter, wash, dry, and crush into 200μm particles to obtain activated seafoam stone;

[0033](2) Preparation of magnetic iron ferric oxide / nickel oxide precursor: dissolving ferric nitrate and nickel nitrate in ethylene glycol according to the solid-liquid ratio of 0.2mg / ml and 0.07mg / ml respectively, and then adding anhydrous sodium acetate to make The mass ratio of it to ethylene glycol is 0.1, after uniform dispersion, the precursor solution is obtained;

[0034] (3) Hydrothermal preparation of magnetic ferroferric oxide / nickel oxide modified sepiolite: disperse the activated sepiolite in the precursor solution at a solid-to-liquid ratio of 0.02g / ml, and transfer it to polytetrafluoroethylene after magnetic stirring In an ethylene-lined reactor, con...

Embodiment 2

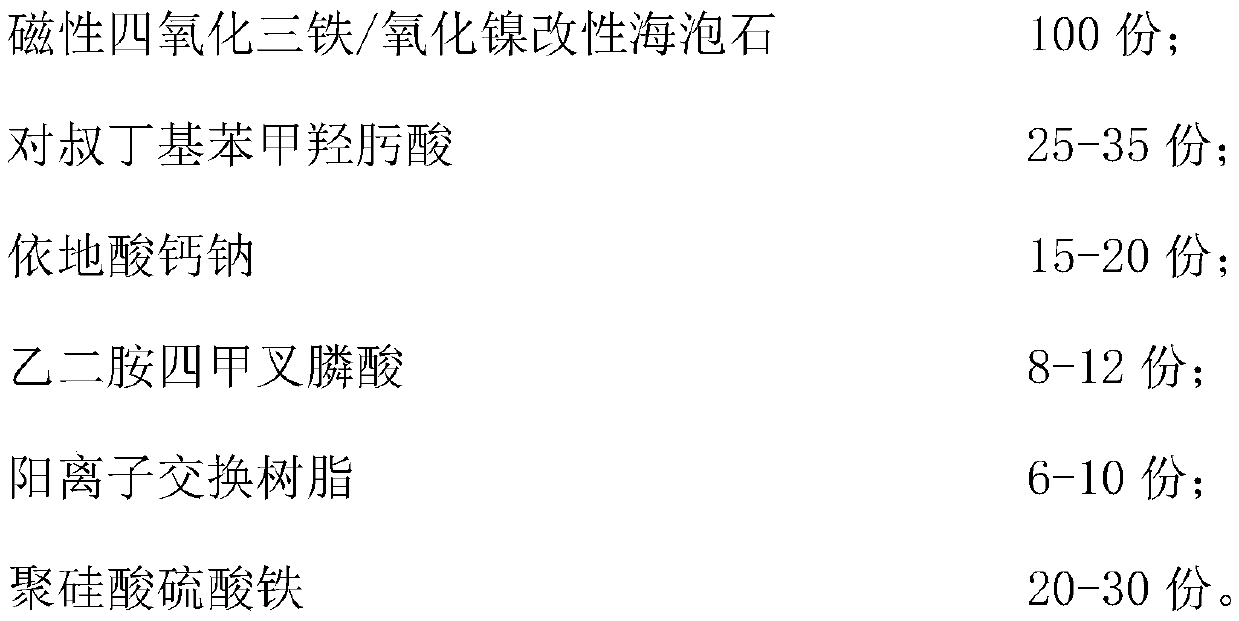

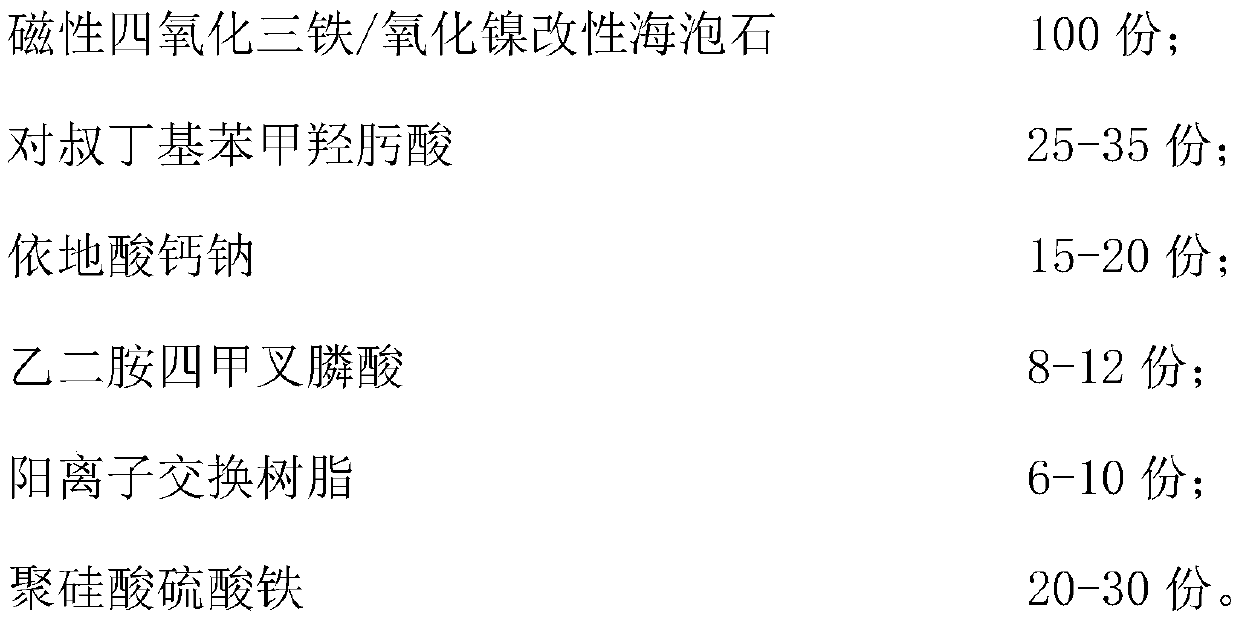

[0035] Embodiment 2: Preparation of magnetic nanoadsorbent

[0036] With 100 parts of magnetic iron ferric oxide / nickel oxide modified sepiolite obtained in Example 1 and 30 parts of p-tert-butylbenzohydroxamic acid, 18 parts of edetate calcium sodium, 10 parts of ethylenediamine tetramethylene Phosphonic acid, 8 parts of cation exchange resin, and 25 parts of polysilicate ferric sulfate are uniformly mixed, and the obtained composite is the magnetic nano-adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com