Test structure for monitoring backside-illumination electronegativity intensity and process integration method

A test structure, back-illuminated technology, used in semiconductor/solid-state device testing/measurement, circuits, electrical components, etc., can solve the problems of prolonged development cycle, lag, waste of silicon wafers, etc., and achieve low process cost and low test cost. , Test the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] First of all, the structure of the existing back-illuminated image sensor will be described in conjunction with the accompanying drawings:

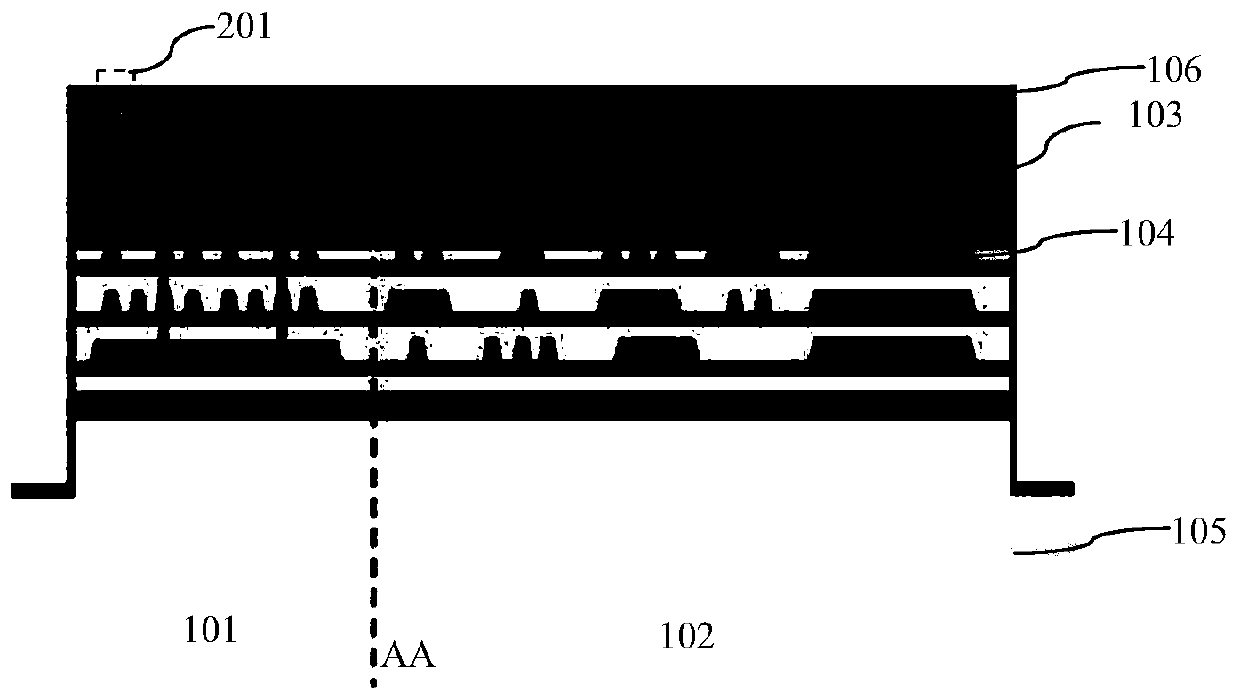

[0060] like Figure 1A As shown, it is a schematic structural diagram of an existing back-illuminated image sensor; the existing back-illuminated image sensor includes a pixel area 101 and a peripheral area 102, which are respectively located on the left and right sides of the dotted line AA; on a semiconductor substrate such as a silicon substrate 103 A device structure is formed on it, and the semiconductor substrate 103 is also called a device sheet; the device structure in the pixel region 101 includes a photodiode, that is, a photodiode. Usually, the semiconductor substrate 103 is P-type doped, and the photodiode is formed on a P-type semiconductor The substrate 103 is composed of an N-type photosensitive doped region formed in the P-type semiconductor substrate 103 . CMOS devices are formed in the peripheral region 102 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com