Device and method for recycling ethyl alcohol in refined mother solution of doxycycline hyclate

A technology of doxycycline hydrochloride and a recovery method, applied in the pharmaceutical field, can solve problems such as inability to treat solid waste, and achieve the effects of high recovery rate, stable process and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

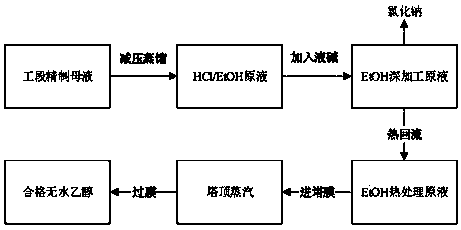

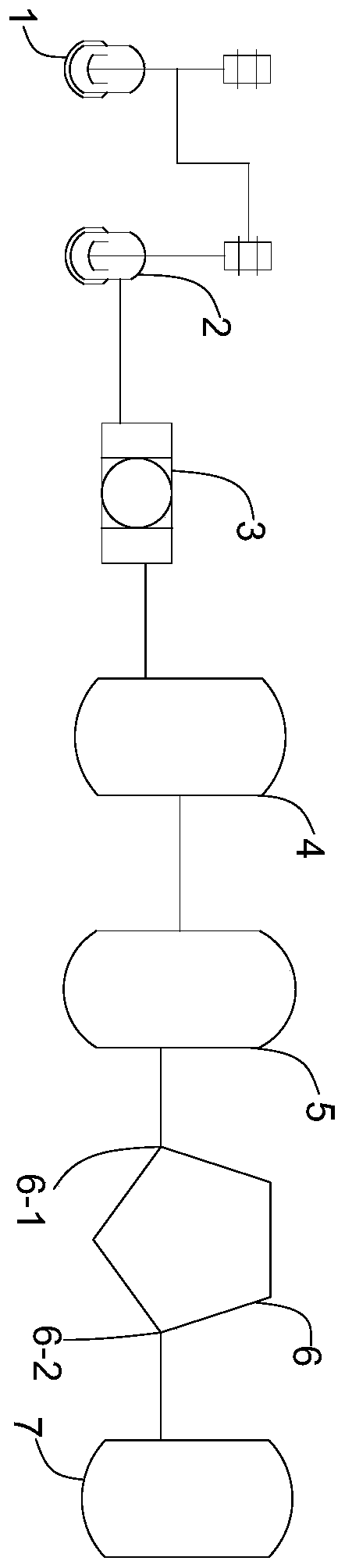

Method used

Image

Examples

Embodiment 1

[0030] Put 1500L doxycycline hydrochloride mother liquor (1706ppm ethyl chloride content) into a 3000L distillation still, open the vacuum valve, keep the vacuum at about -0.1Mpa, raise the temperature to 30°C, and cool the distillate vapor through a 0-10°C condenser Liquefied into the neutralization kettle. The vacuum distillation can be stopped when more than 1350L fraction is collected in the neutralization tank. Add 32% liquid caustic soda to the neutralization kettle under ice-brine cooling, control the temperature below 40°C, and adjust the pH to 9-10. The mixture of ethanol and sodium chloride in the kettle is separated by filtration, and the ethanol solution is vaporized at high temperature and filtered through a vaporization membrane. , to obtain 1278L of absolute ethanol finished product, the yield is about 85.2%, the content is 99.8%, the moisture is 0.1%, and the ethyl chloride content is 138ppm. Specifically, in this embodiment, the vaporization membrane is selec...

Embodiment 2

[0032] Put 1500L doxycycline hydrochloride mother liquor (2201ppm ethyl chloride content) into a 3000L distillation still, open the vacuum valve, keep the vacuum at about -0.08Mpa, raise the temperature to 40°C, and cool the distillate vapor through a 0-10°C condenser Liquefied into the neutralization kettle. The vacuum distillation can be stopped when more than 1350L fraction is collected in the neutralization tank. Add 32% liquid caustic soda to the neutralization kettle under ice-brine cooling, control the temperature below 40°C, adjust the pH to 9-10, filter and separate the mixture of ethanol and sodium chloride, vaporize the ethanol solution at high temperature and filter it through a vaporization membrane to obtain anhydrous The finished product of ethanol is 1312L, the yield is about 87.5%, the content is 99.75%, the moisture is 0.15%, and the ethyl chloride content is 121ppm. Specifically, in this embodiment, the vaporization membrane is selected from the NaA type in...

Embodiment 3

[0034] Put 1500L doxycycline hydrochloride mother liquor (2250ppm ethyl chloride content) into a 3000L distillation still, open the vacuum valve, keep the vacuum at about -0.09Mpa, raise the temperature to 35°C, and cool the distillate steam through a 0-10°C condenser Liquefied into the neutralization kettle. The vacuum distillation can be stopped when more than 1350L fraction is collected in the neutralization tank. Add 32% liquid caustic soda to the neutralization kettle under ice-brine cooling, control the temperature below 40°C, and adjust the pH to 9-10. The mixture of ethanol and sodium chloride in the kettle is separated by filtration, and the ethanol solution is vaporized at high temperature and filtered through a vaporization membrane. Obtain 1304L of absolute ethanol finished product, the yield is about 86.9%, the content is about 99.8%, the moisture content is 0.1%, and the ethyl chloride content is 104ppm. Specifically, in this embodiment, the vaporization membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com