Composite deoxidizing scale inhibitor applied to low-hardness water of boiler and preparation method of composite deoxidizing scale inhibitor

A scale inhibitor, low hardness technology, applied in water softening, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of long process time, affecting production operation, cumbersome operation, etc., to achieve easy degradation , Conducive to environmental protection production, the effect of reducing waste liquid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

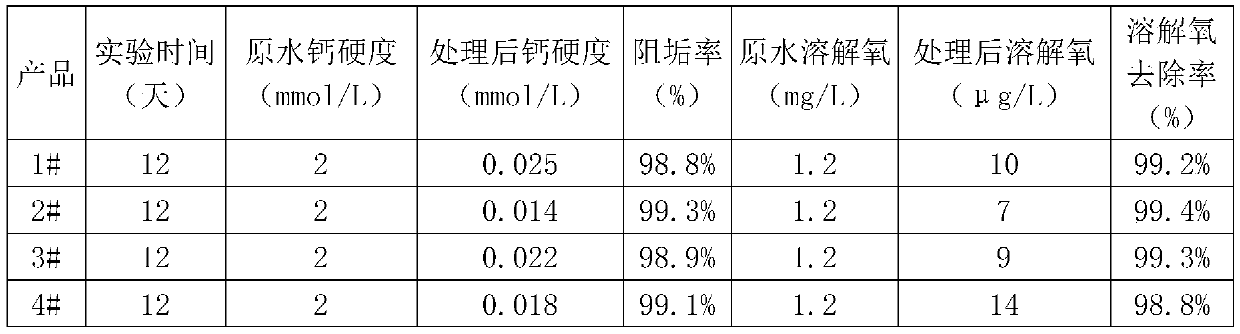

Examples

preparation example Construction

[0025] A preparation method for a composite deoxidizer and scale inhibitor applied to boiler low-hardness water, comprising the following methods:

[0026] 1) Preparation of sodium lignosulfonate-maleic anhydride copolymer: take sodium lignosulfonate as raw material, maleic anhydride as monomer, ammonium persulfate as initiator, and the addition of ammonium persulfate is 1 / 2 of the total mass of the copolymer 0.5%-4%, sodium lignosulfonate and maleic anhydride are mixed according to the mass ratio of 0.8-1.5:0.5-2, the reaction temperature is 40-60°C, the reaction time is 2-4h, and the graft copolymerization reaction is carried out to obtain the copolymer;

[0027] 2) Add the sodium lignosulfonate-maleic anhydride copolymer obtained in step 1) into the reaction kettle at room temperature, then slowly add phytic acid, 3-methoxypropylamine, hydroxyethylethylenediaminetriacetic acid , acetaldehyde oxime, and deionized water are added in batches. During the feeding process, the te...

Embodiment 1

[0031] A composite deoxidizer and scale inhibitor applied to low-hardness water in boilers. The composition and parts by weight of the composite deoxidizer and scale inhibitor are: 10 parts of phytic acid, 18 parts of acetaldehyde oxime, 3-methoxypropylamine 15 parts, 25 parts of sodium lignosulfonate-maleic anhydride copolymer, 8 parts of hydroxyethyl ethylenediamine triacetic acid, 22 parts of deionized water.

[0032] Preparation:

[0033] 1) Preparation of sodium lignosulfonate-maleic anhydride copolymer: take sodium lignosulfonate as raw material, maleic anhydride as monomer, ammonium persulfate as initiator, and the addition of ammonium persulfate is 1 / 2 of the total mass of the copolymer 0.5%, sodium lignosulfonate and maleic anhydride in a mass ratio of 0.8:1.2, the reaction temperature is 45°C, the reaction time is 3h, and the graft copolymerization reaction is carried out to obtain a copolymer;

[0034] 2) Under room temperature conditions, in the reaction kettle th...

Embodiment 2

[0036] A composite deoxidizer and scale inhibitor applied to low-hardness water in boilers. The composition and parts by weight of the composite deoxidizer and scale inhibitor are: 22 parts of phytic acid, 15 parts of acetaldehyde oxime, 3-methoxypropylamine 12 parts, 20 parts of sodium lignosulfonate-maleic anhydride copolymer, 10 parts of hydroxyethyl ethylenediamine triacetic acid, 20 parts of deionized water.

[0037] Preparation:

[0038] 1) prepare sodium lignosulfonate-maleic anhydride copolymer, take sodium lignosulfonate as raw material, maleic anhydride is monomer, ammonium persulfate is initiator, and the addition of ammonium persulfate is the copolymer gross mass 4%, sodium lignosulfonate and maleic anhydride in a ratio of 1:1 by mass, the reaction temperature is 40°C, the reaction time is 4h, and graft copolymerization is carried out to obtain a copolymer;

[0039] 2) Under room temperature conditions, in the reaction kettle that will prepare sodium lignosulfonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com