Flexible driver

A flexible driver and flexible technology, applied in the field of training and rehabilitation equipment, can solve the problems of ignoring hand joint rehabilitation training, low bending range, high cost, etc., and achieve the effects of avoiding long-term rigidity, simplifying the structure, and avoiding secondary injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

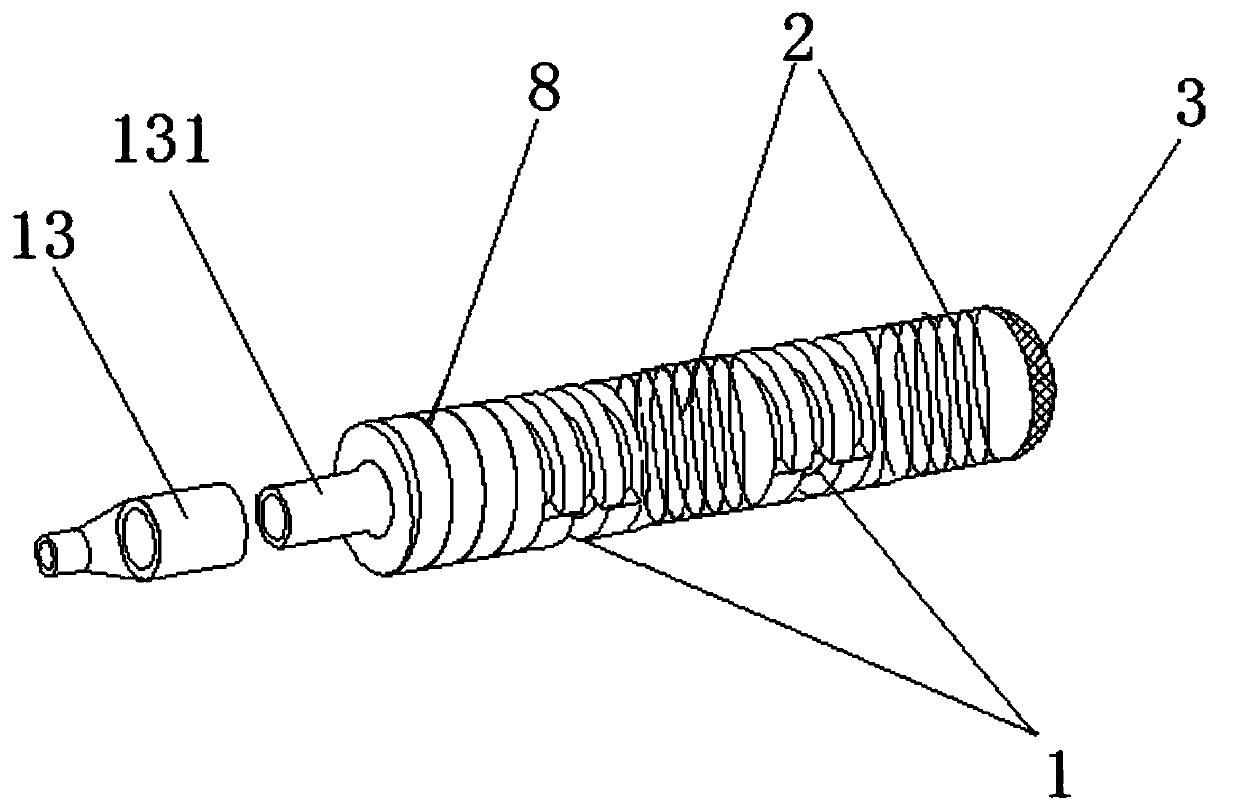

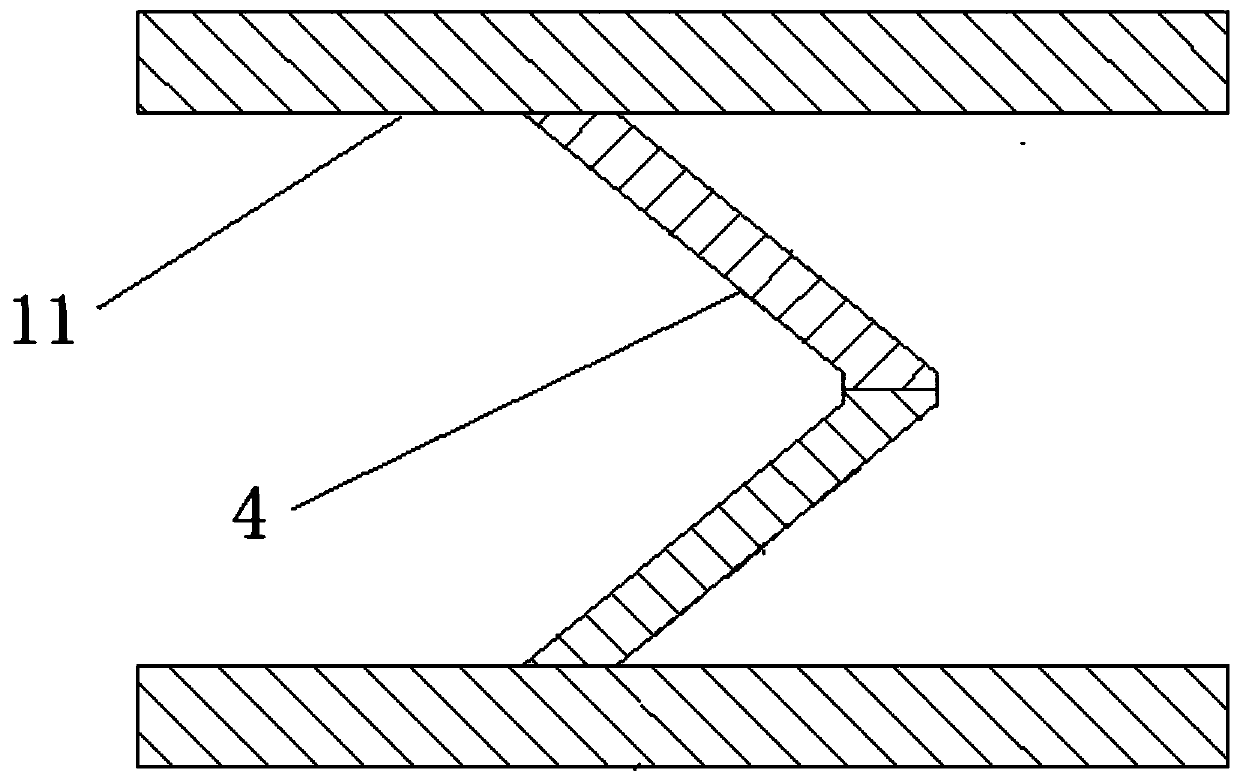

[0052] Two extension drive units 2, two bending drive units 1, a torsion drive unit 8 and a flexible cover 3 constitute a thumb drive 16, and the connection sequence is torsion drive unit 8, bending drive unit 1, and extension drive unit 2. The bending drive unit 1, the elongation drive unit 2, the flexible cover 3; the length of the partition 5 located in the thumb drive 16 is the sum of the length of the proximal phalanx of the thumb and the distal phalanx of the thumb; the torsion drive unit 8 A flexible valve 4 is provided, and the torsion-type drive unit 8 communicates with the air distribution mechanism 9 through a reducing joint 13.

Embodiment 2

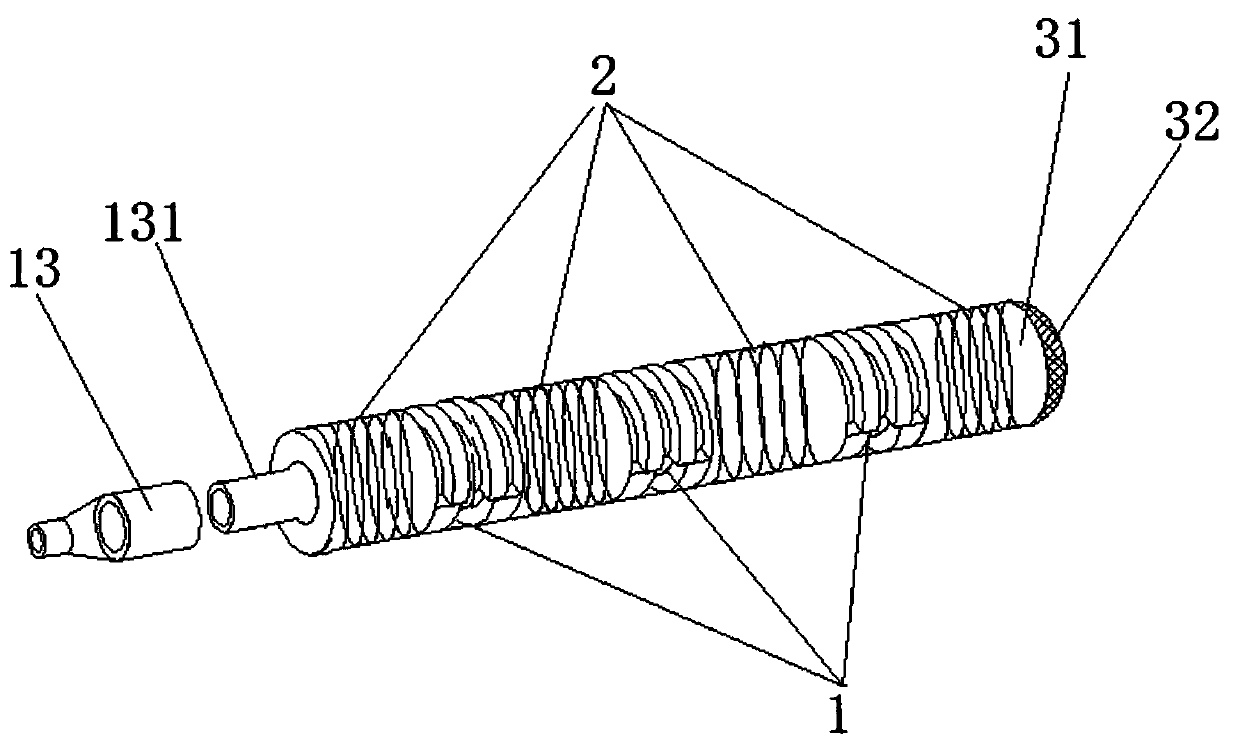

[0054] Four extension drive units 2, three bending drive units 1 and one flexible cover 3 constitute a finger drive 17, and the connection sequence is extension drive unit 2, bending drive unit 1, extension drive unit 2, bending drive unit 1, Extension drive unit 2, bending drive unit 1, extension drive unit 2, flexible cover 3; the length value of the partition 5 located in the finger drive 17 is corresponding to the near phalanx of the finger, the corresponding middle phalanx and the corresponding far phalanx of the finger The sum of the lengths; where a flexible valve 4 is provided in the elongation driving unit 2 located at the palm joint, and the flexible valve 4 is in communication with the air distribution mechanism 9 through a reducing joint 13.

Embodiment 3

[0056] Two extension drive units 2, two bending drive units 1, a torsion drive unit 8 and a flexible cover 3 constitute a thumb drive 16, and the connection sequence is torsion drive unit 8, bending drive unit 1, and extension drive unit 2. The bending drive unit 1, the elongation drive unit 2, the flexible cover 3; the length of the partition 5 located in the thumb drive 16 is the sum of the length of the proximal phalanx of the thumb and the distal phalanx of the thumb; the torsion drive unit 8 A flexible valve 4 is provided, and the torsion-type drive unit 8 communicates with the air distribution mechanism 9 through a reducing joint 13.

[0057] Four extension drive units 2, three bending drive units 1 and one flexible cover 3 constitute a finger drive 17, and the connection sequence is extension drive unit 2, bending drive unit 1, extension drive unit 2, bending drive unit 1, Extension drive unit 2, bending drive unit 1, extension drive unit 2, flexible cover 3; the length va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com