Electromagnetic vibration power supply method based on folding cantilever beam

An electromagnetic vibration and power supply method technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of low space utilization, reduce the volume of energy collectors, poor practicability, etc., achieve enhanced output voltage, reduce magnetic induction line leakage, Effect of improving magnetic flux utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Aiming at the characteristics of gasoline engines, diesel engines and other mechanical equipment that generate specific frequency vibrations during operation, the electromagnetic vibration power supply method based on folded cantilever beams in this embodiment is used to collect surface vibration energy and convert these energy into electrical energy for micro-miniature electronic systems. Power supply, the micro-miniature electronic system is a miniature wireless sensor node, and the power supply connected to the energy harvester can extend the service life of the battery.

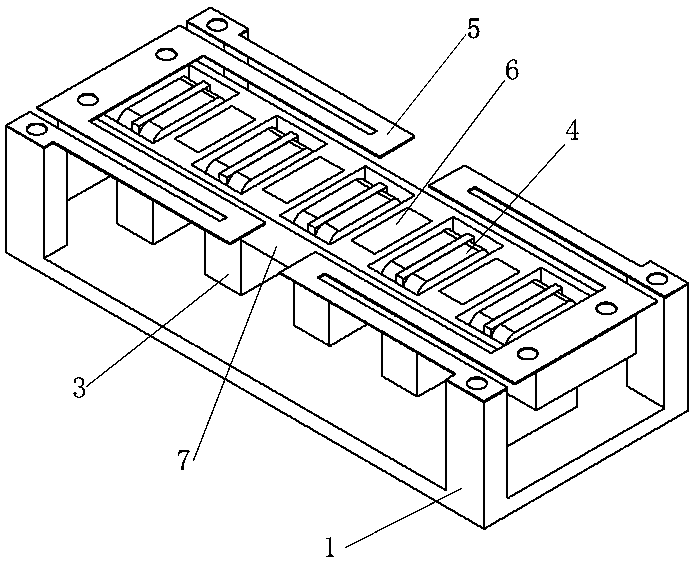

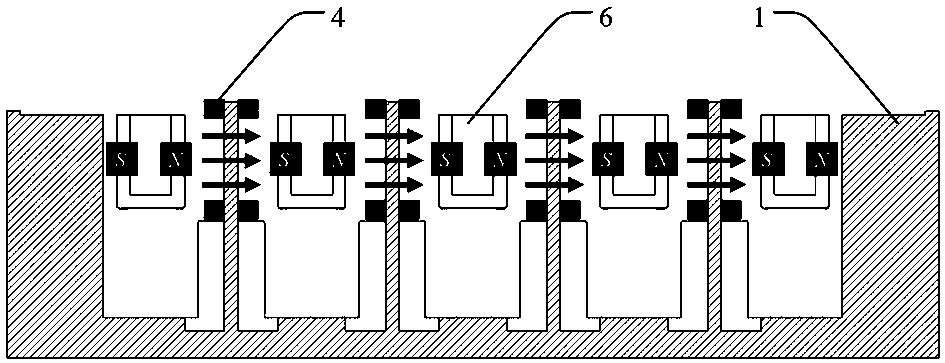

[0023] Such as figure 1 and figure 2 As shown, the energy harvester includes a base 1 , a power management circuit (not shown in the figure), a coil support base 3 , a coil 4 , a folded cantilever beam 5 , a permanent magnet 6 and a mass 7 . The base 1 folds the cantilever beam 5 to provide fixed support, and provides fixed support for the coil 4 through the coil support base 3 . The support bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com