Preparation method of active metal oxide-carbonized bacterial cellulose electrode material

A technology of bacterial cellulose and active metals, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

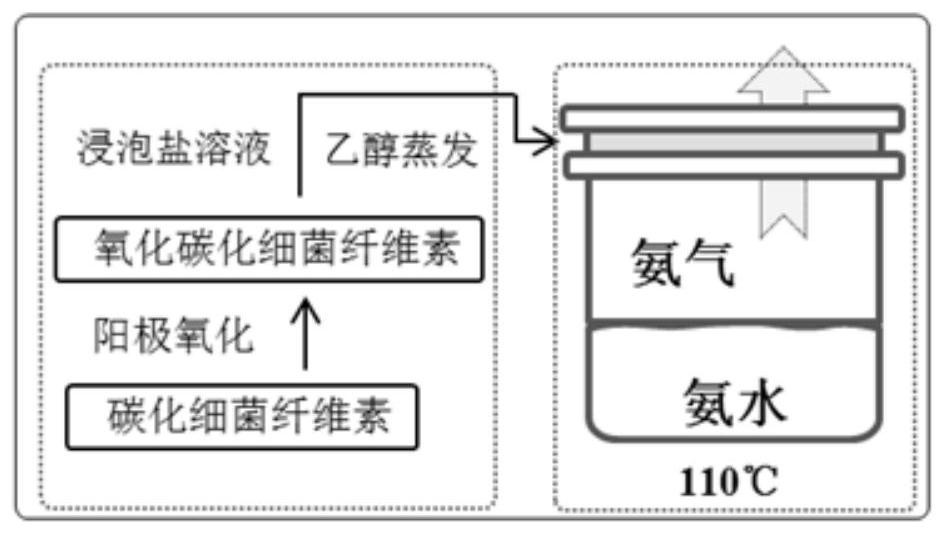

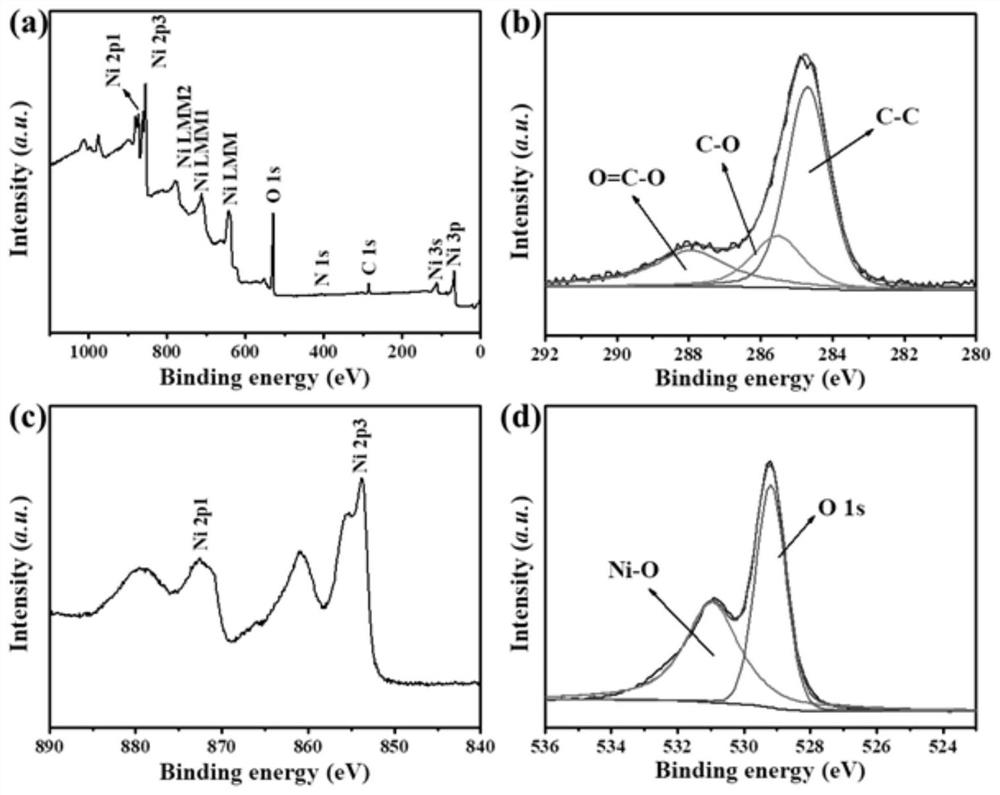

[0028] In step 1, the surface of the carbonized bacterial cellulose fiber is oxidized by a constant potential anodic oxidation method, and the oxidation potential and oxidation time are 2V and 300s, respectively, to obtain a hydrophilic flexible carbonized bacterial cellulose material.

[0029] Step 2, soaking the hydrophilic flexible carbonized bacterial cellulose material in 0.02M nickel nitrate solution for 2 hours, and then volatilizing ethanol at 60° C. to obtain the nickel nitrate-carbonized bacterial cellulose material.

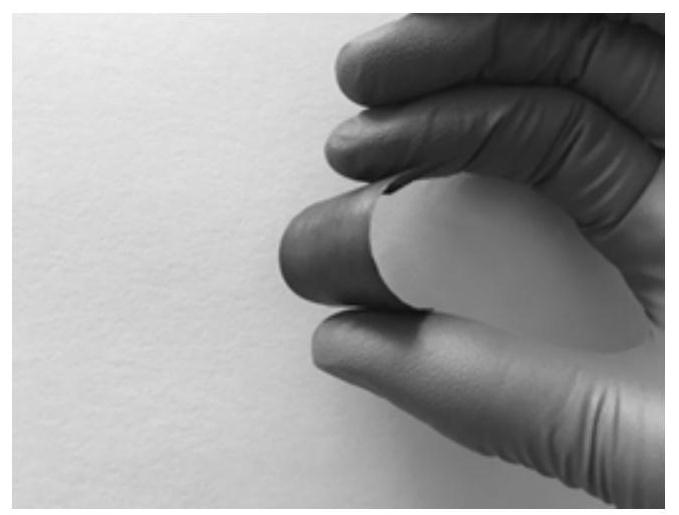

[0030] Step 3, cover the flexible nickel nitrate-carbonized bacterial cellulose membrane material in a closed ammonia beaker, and make ammonia gas permeate the nickel nitrate-carbonized bacterial cellulose membrane at 110°C, ammonia gas and carbonized bacterial cellulose fiber Nickel nitrate on the surface reacts to obtain a flexible nickel oxide-carbonized bacterial cellulose material.

Embodiment 2

[0032] In step 1, the surface of the carbonized bacterial cellulose fiber is oxidized by a constant potential anodic oxidation method, and the oxidation potential and oxidation time are 5V and 100s, respectively, to obtain a hydrophilic flexible carbonized bacterial cellulose material.

[0033] Step 2: Soak the hydrophilic flexible carbonized bacterial cellulose material in 0.05M nickel nitrate solution for 1 hour, and then volatilize ethanol at 60° C. to obtain nickel nitrate-carbonized bacterial cellulose material.

[0034] Step 3, cover the flexible nickel nitrate-carbonized bacterial cellulose membrane material in a closed ammonia beaker, and make ammonia gas permeate the nickel nitrate-carbonized bacterial cellulose membrane at 120°C, ammonia gas and carbonized bacterial cellulose fiber Nickel nitrate on the surface reacts to obtain a flexible nickel oxide-carbonized bacterial cellulose material.

Embodiment 3

[0036] In step 1, the surface of the carbonized bacterial cellulose fiber is oxidized by a constant potential anodic oxidation method, and the oxidation potential and oxidation time are 5V and 300s, respectively, to obtain a hydrophilic flexible carbonized bacterial cellulose material.

[0037] Step 2, soaking the hydrophilic flexible carbonized bacterial cellulose material in 0.1M nickel nitrate solution for 1 hour, and then volatilizing ethanol at 60° C. to obtain the nickel nitrate-carbonized bacterial cellulose material.

[0038] Step 3, cover the flexible nickel nitrate-carbonized bacterial cellulose membrane material in a closed ammonia beaker, and make ammonia gas permeate the nickel nitrate-carbonized bacterial cellulose membrane at 130°C, ammonia gas and carbonized bacterial cellulose fiber Nickel nitrate on the surface reacts to obtain a flexible nickel oxide-carbonized bacterial cellulose material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com