Tensile reinforced concrete chute lining structure

A reinforced concrete, tensile-type technology, which is applied in the field of mine shaft engineering, can solve problems such as poor effect, accelerated shaft deformation and damage, and fast wear speed, and achieves a remarkable tensile effect, eliminating bonding, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

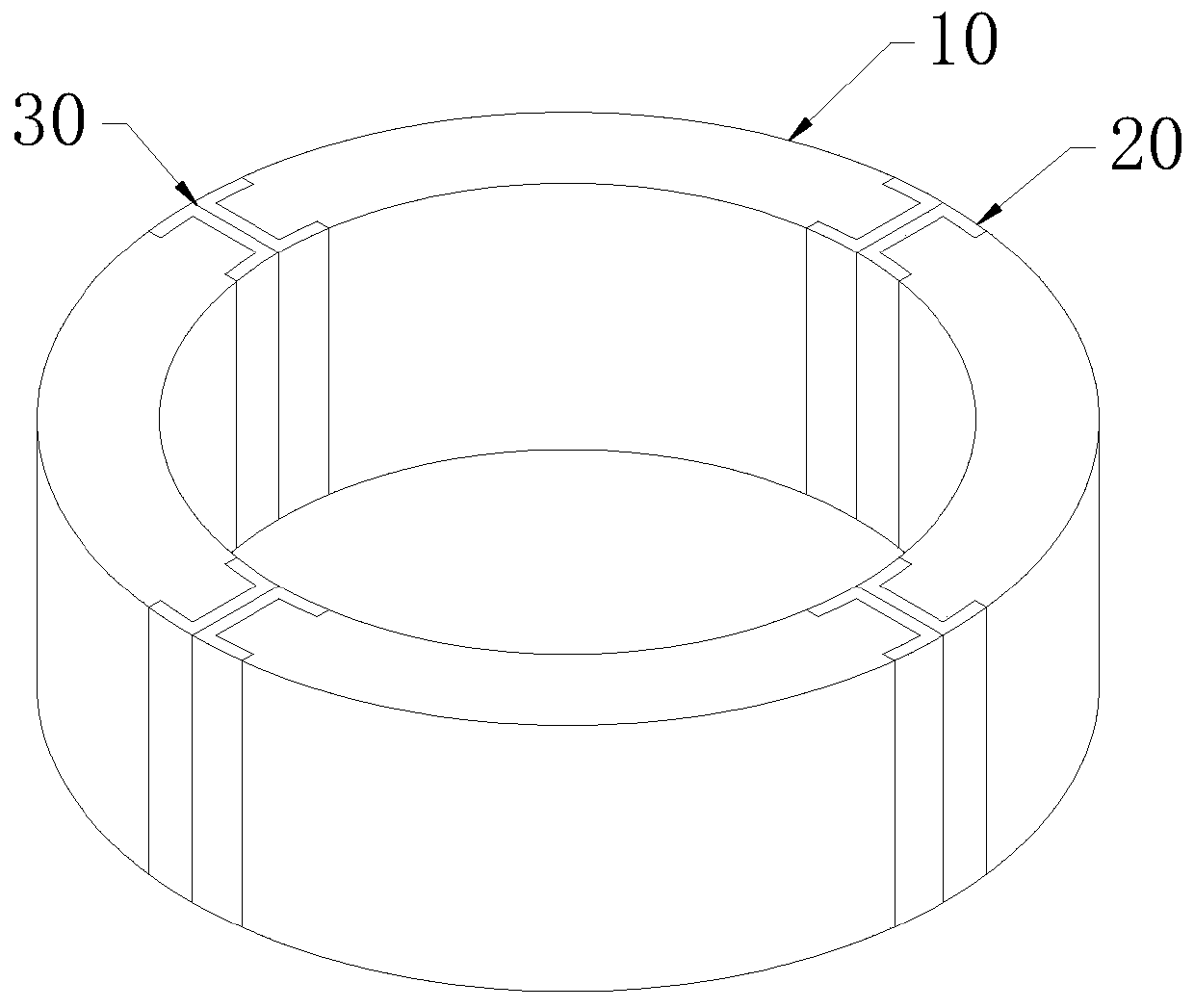

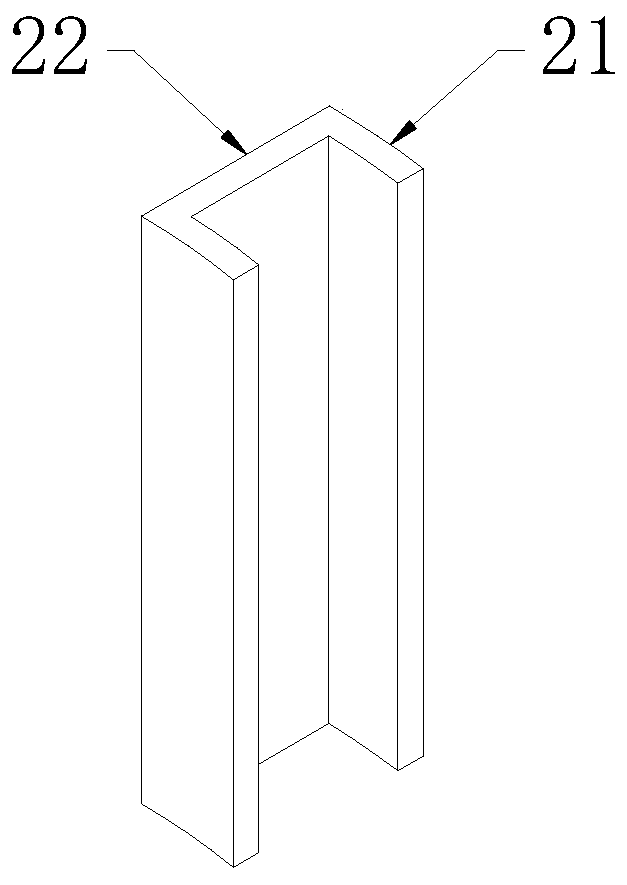

[0030] like Figure 1~3 As shown, a tensile reinforced concrete chute lining structure includes several lining units 10 of a reinforced concrete structure connected head to tail to form a ring and steel channels 20 arranged at both ends of the lining unit 10. The lining unit 10 is Arc-shaped, and the lining unit 10 is provided with a steel cage skeleton 11, the steel channel 20 includes an integrated back plate 22 and guard plates 21 on both sides of the back plate 22, the back plate 22 and the guard plate 21 are "[" shape, the back plates 22 of adjacent steel channels 20 are close to each other, and deformation seams 30 are formed between the back plates 22 of adjacent steel channels 20 .

[0031] In this embodiment, the lining unit 10 is prefabricated reinforced concrete. During construction, it is only necessary to hoist the lining unit 10 to a designated installation location, and after the steel channels 20 are clamped at both ends, they are assembled into a ring-shaped c...

Embodiment 2

[0035] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the lining unit 10 and the steel channel 20 are an integral prefabricated structure, and the steel channel 20 and the reinforcement cage frame 11 inside the lining unit 10 are welded and fixed during prefabrication. In this way, the splicing and fixing of the steel channel 20 and the lining unit 10 can be realized during prefabrication, and the assembly operation of the steel channel 20 and the lining unit 10 can be omitted when the lining is installed in the chute, which greatly improves the installation efficiency and improves the steel channel. 20 and the connection strength and stability of the lining unit 10.

Embodiment 3

[0037] like Figure 5 As shown, the difference between this embodiment and Embodiment 2 is that: the main body of the lining unit 10 is provided with a grouting hole 12, and the grouting hole 12 extends to the back of the lining unit 10 in contact with the chute wall.

[0038] The purpose of reserving the grouting hole 12 is that after the lining structure is formed, grouting behind the wall can be carried out through the grouting hole 12, and even the plastic area of the surrounding rock can be grouted, so as to densely fill the gap behind the wall and strengthen the weak surrounding rock, so that the lining It is integrated with the surrounding rock for joint load, so it has the advantages of increasing the equivalent thickness of the lining, improving the waterproof condition of the lining, and loosening the rock mass after stabilizing the wall. In addition, when the lining unit 10 is prefabricated, the grouting hole 12 is easy to leave , will not affect the lining streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com