Multifunctional graphene modified non-woven fabric and preparation method thereof

A graphene modification, non-woven technology, applied in non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., to improve the intrinsic conductivity, expand the scope of application, and achieve good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

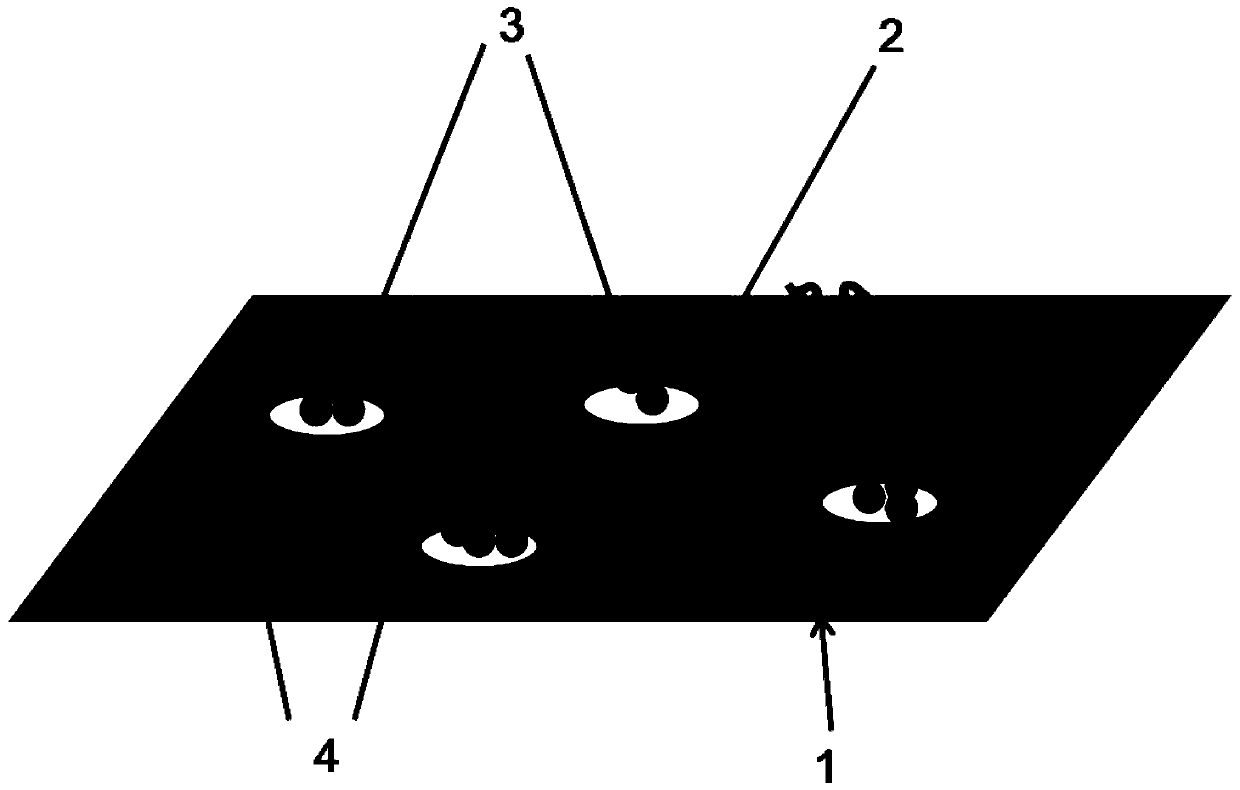

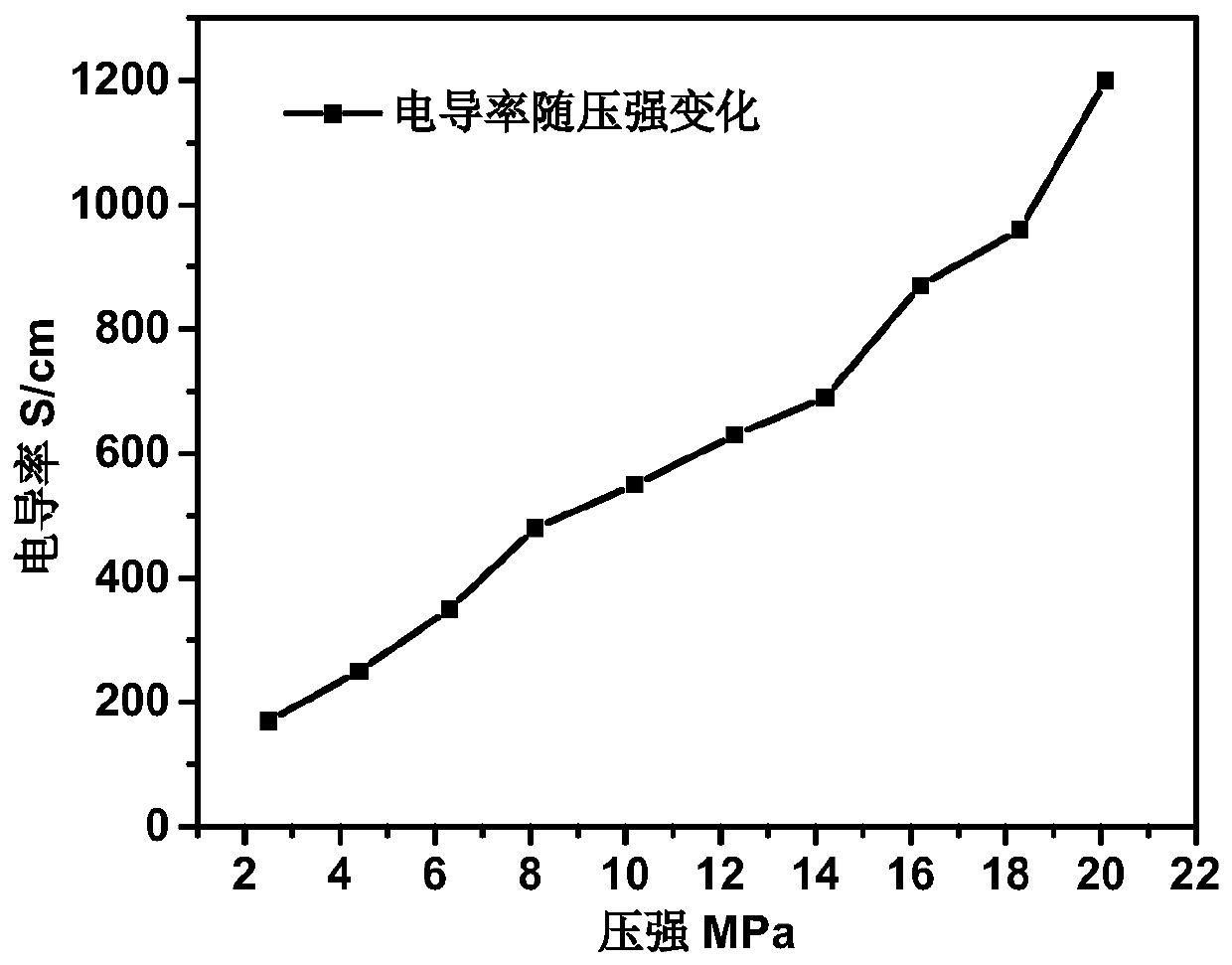

Image

Examples

Embodiment 1

[0031] (1) Mix the low DBP value nano carbon black and the high DBP value nano carbon black according to the mass ratio of 4:1, the DBP value of the high DBP value nano carbon black is 360, and the DBP value of the low DBP value nano carbon black is 240 ;

[0032] (2) 10 parts of step (1) gained mixed carbon black is added the aqueous dispersion of 50 mass parts graphene oxide, carry out high-speed shear dispersion by emulsifying homogenizer, the mass concentration of graphene oxide aqueous dispersion is 1%; Among them, the lateral size of graphene oxide is 1-10 μm, the vertical size is 0.3-1.2 nm, and the carbon-oxygen ratio is 2.5;

[0033] (3) Put the dispersion obtained in step (2) in a hydrothermal reaction kettle, react at 180° C. for 2 hours, cool to room temperature, take out the reactant and dry it by infrared to obtain a graphene-based composite additive.

[0034] (4) the graphene-based composite additive of step (3) gained is premixed with polypropylene slices, and t...

Embodiment 2

[0038] (1) Mix the low DBP value nano carbon black and the high DBP value nano carbon black according to the mass ratio of 3:1, the DBP value of the high DBP value nano carbon black is 400, and the DBP value of the low DBP value nano carbon black is 240 ;

[0039] (2) 10 parts of step (1) gained mixed carbon black is added the aqueous dispersion of 50 mass parts graphene oxide, carry out high-speed shear dispersion by emulsifying homogenizer, the mass concentration of graphene oxide aqueous dispersion is 3%; Among them, the lateral size of graphene oxide is 1-10 μm, the vertical size is 0.3-1.2 nm, and the carbon-oxygen ratio is 2.5;

[0040] (3) Put the dispersion obtained in step (2) in a hydrothermal reaction kettle, react at 180° C. for 2 hours, cool to room temperature, take out the reactant and dry it by infrared to obtain a graphene-based composite additive.

[0041] (4) the graphene-based composite additive of step (3) gained is premixed with polypropylene slices, and...

Embodiment 3

[0045] (1) Mix the low DBP value nano carbon black and the high DBP value nano carbon black according to the mass ratio of 3:1, the DBP value of the high DBP value nano carbon black is 380, and the DBP value of the low DBP value nano carbon black is 280 ;

[0046] (2) 10 parts of step (1) gained mixed carbon black is added the aqueous dispersion of 50 mass parts graphene oxide, carry out high-speed shear dispersion by emulsifying homogenizer, the mass concentration of graphene oxide aqueous dispersion is 6%; Among them, the lateral size of graphene oxide is 1-10 μm, the vertical size is 0.3-1.2 nm, and the carbon-oxygen ratio is 2.5;

[0047] (3) Put the dispersion obtained in step (2) in a hydrothermal reaction kettle, react at 180° C. for 2 hours, cool to room temperature, take out the reactant and dry it by infrared to obtain a graphene-based composite additive.

[0048] (4) the graphene-based composite additive of step (3) gained is premixed with polypropylene slices, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Vertical size | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com