Fluidized pit backfill soil adopting contaminated soil as raw material and construction method

A construction method and a technology of polluting soil, which is applied in the fields of earth drilling, filling, mining equipment, etc., can solve the problems of unfavorable environmental protection and the development of low-carbon economy, the pollution of the environment by the preparation of raw materials, the pollution of dust in the environment, etc., and achieve superior stability , Improve strength and availability, and prevent secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

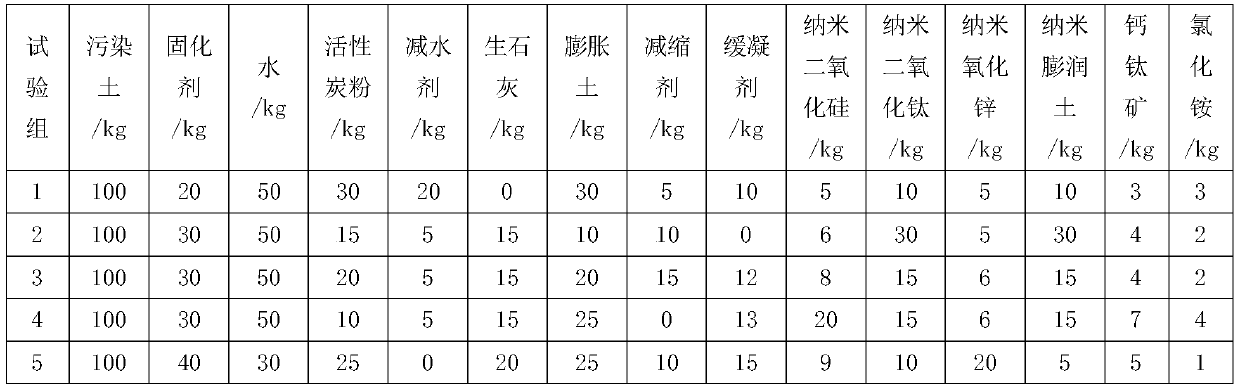

[0027] A mine pit in Huainan City needs to be backfilled. At the same time, there is a large amount of river dredging silt that needs to be treated. The silt is rich in a large amount of pesticide residues (herbicides). Considering comprehensively, the dredged silt is used as the contaminated soil raw material to prepare fluidized mine pit backfill soil to backfill the mine pit. The specific implementation steps are as follows:

[0028] (1) Determine the raw material ratio for on-site construction: According to the laboratory test results, determine the raw material ratio of the contaminated soil. The control standards include the fluidity and the diffusion characteristics of soil pollutants after solidification. The components of the dredged silt are determined to be: contaminated soil 95~ 105 parts, 30 parts of curing agent, 50 parts of water, 20 parts of activated carbon powder, 5 parts of water reducing agent, 15 parts of quicklime, 20 parts of expansive soil, 15 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com