Oil-water separation component of oil separator

A technology of oil-water separation and oil separator, which is applied in the direction of grease/oily substance/suspton removal device, water/sewage treatment, chemical instruments and methods, etc., which can solve the problems of high cost and low cost of centrifugal separation, and achieve maintenance Oil scraping continuity, improved efficiency, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

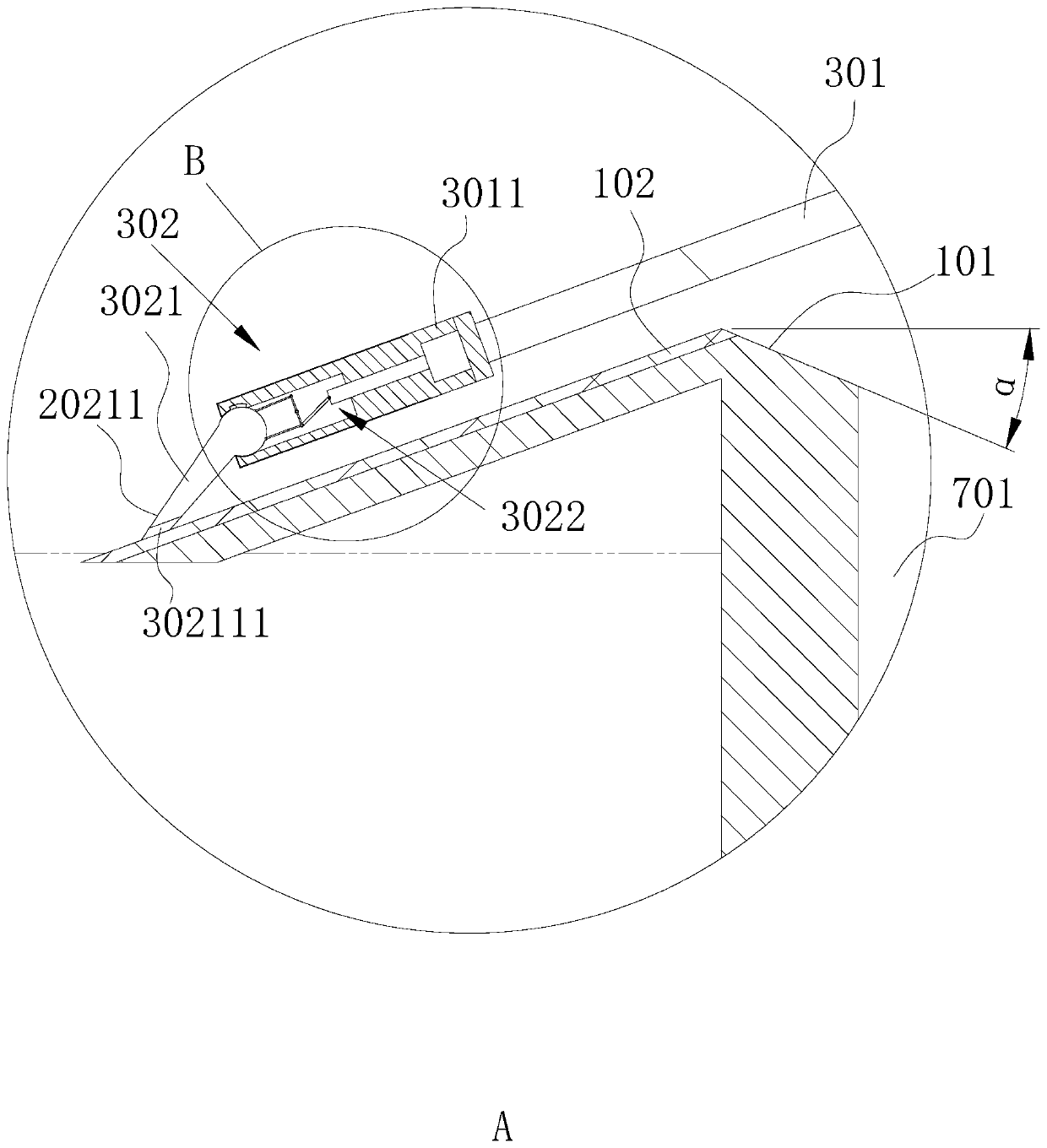

[0046] refer to figure 1 as well as figure 2 , this embodiment discloses an oil-water separation assembly of an oil separator, including an oil attachment plate 1 , a pneumatic conveying assembly 2 and an oil scraping assembly 3 .

[0047] refer to figure 2 , in this embodiment, a separator 4 is arranged in the oil separator, and the separator 4 divides the space inside the oil separator into a solid-liquid separation chamber 5, an air bubble generation chamber 6, an oil-water separation chamber 7, and a drainage chamber 8. The separation chamber 5 is provided with a filter screen 501 for filtering solid impurities and realizing solid-liquid separation;

[0048] A bubble generator 601 is arranged in the bubble generating chamber 6, and an oil-water separation assembly is arranged in the oil-water separation chamber 7. In this embodiment, the bubble generator 601 is a commonly used microbubble generator 601 on the market;

[0049] The oil-water separation chamber 7 is prov...

Embodiment 2

[0074] refer to Figure 5 as well as Image 6 , this embodiment discloses another oil-water separation assembly for an oil separator. Based on Embodiment 1, the difference between this embodiment and Embodiment 1 is that an oil-water separation membrane 103 is also provided on the oil attachment plate 1, and the oil-water separation membrane 103 Laid on the upper surface of the oil attachment plate 1 and located on the lower surface of the oil-absorbing sponge layer 102, the oil attachment plate 1 is provided with a number of water filter holes 104, and the oil attachment plate 1 is provided with a return water tank 105 communicating with the water filter holes 104. The water tank 105 communicates with the lower surface of the oil-attached plate 1, so that when the air flow blows the oil layer to the oil-attached plate 1, the water layer following the lower layer passes through the oil-water separation membrane 103, the water filter hole 104, and the water return tank 105, and...

Embodiment 3

[0076] This embodiment discloses another oil-water separation assembly for an oil separator. Based on the above-mentioned embodiment, the difference between this embodiment and the above-mentioned embodiment is that the turning drive part is a servo drive motor, and the servo drive motor is arranged in the mounting seat, and The drive end of the servo drive motor is fixed to the arc portion of the oil scraper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com