Synthetic method of citric acid gypsum

A citrate gypsum and synthesis method technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of irregular crystal structure, coarse gypsum particles, and low strength of building gypsum powder, and achieve regular crystal structure, coarse particles, high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

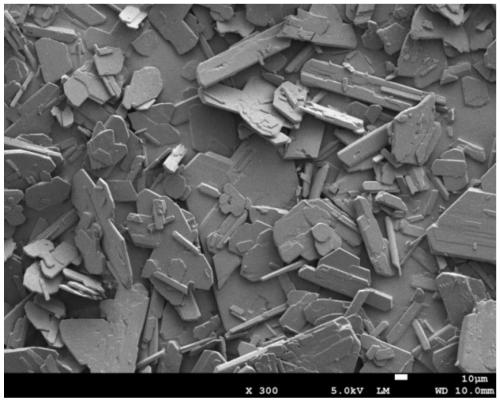

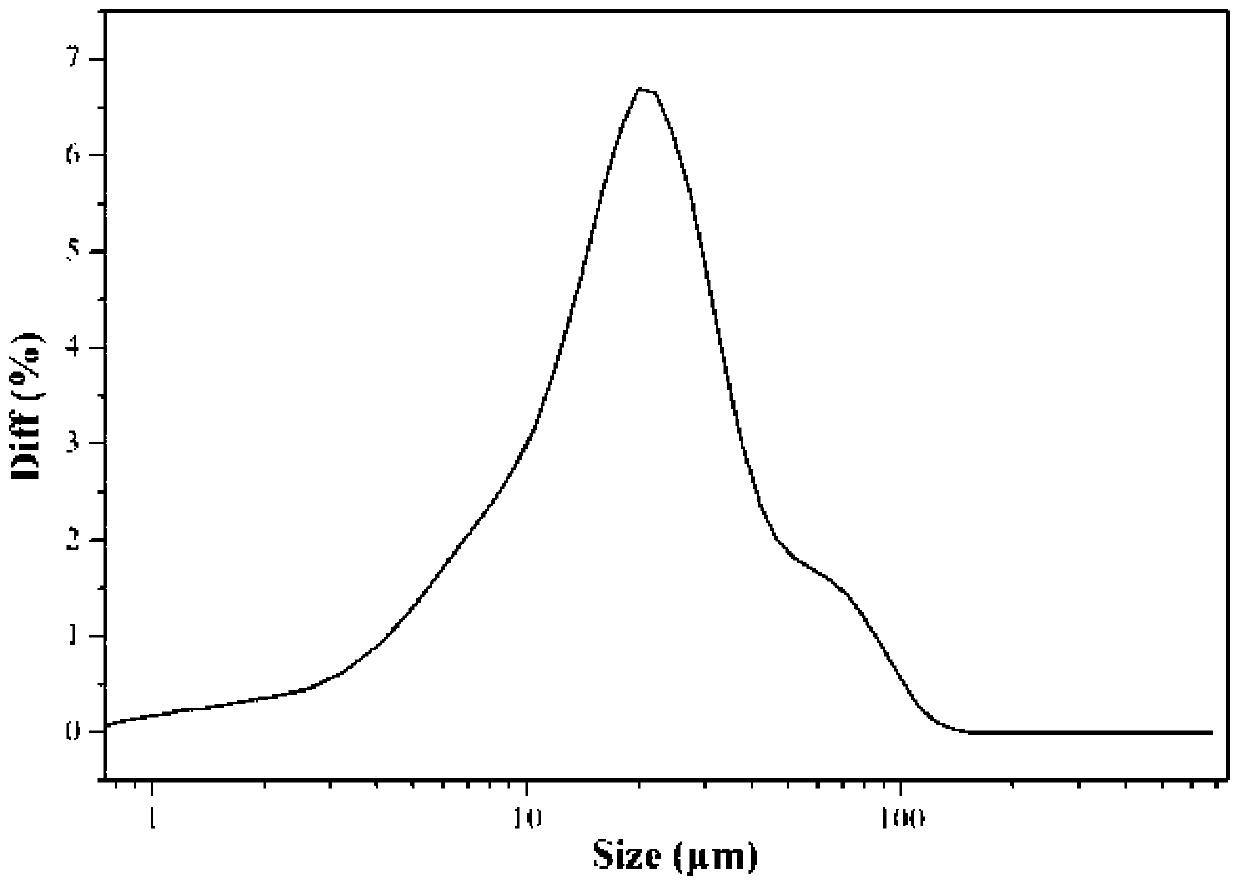

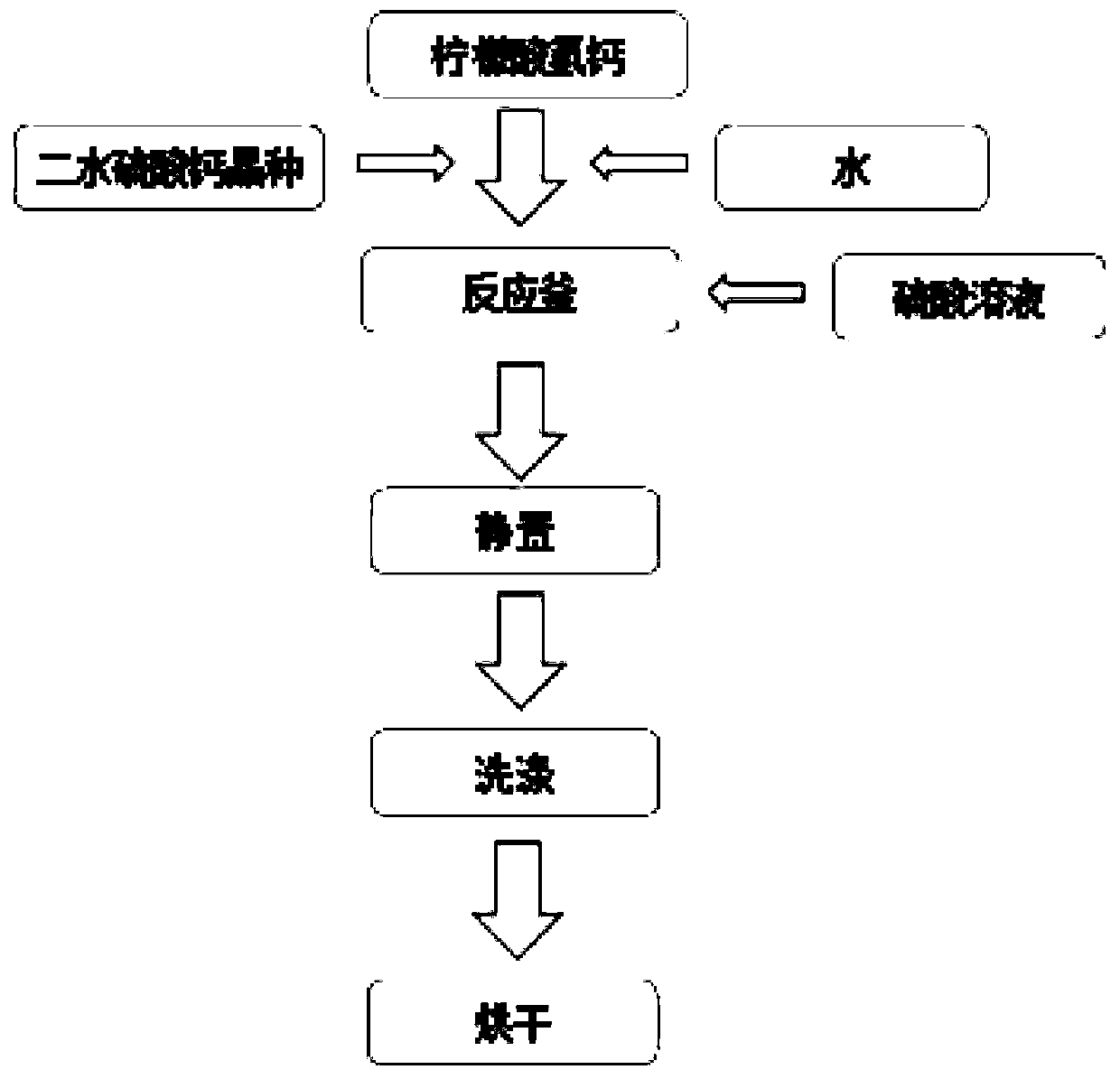

[0037]Example 1: Mix calcium hydrogen citrate (a by-product of Jiangsu Guoxin Xielian Company) and water at a mass ratio of 1:2, the stirring speed is 300r / min, the temperature is 40°C, and dihydrate desulfurized gypsum seeds are added. The diameter is 30 μm, the mass ratio of desulfurized gypsum seed crystals to calcium hydrogen citrate is 1:2, prepare 1mol / L sulfuric acid solution and drop it in at a speed of 0.02mL / s. After the reaction is complete, continue to stir for 20 minutes, and then let it stand for 30 minutes. Finally, wash twice with ethanol and dry at 45°C. The median diameter of citrate gypsum particles prepared under this condition is 83 μm, and the crystal morphology is very regular, such as Figure 4-5 . Referring to the process for preparing building gypsum powder from citric acid gypsum in patent CN 102249577 A, the 2h flexural strength of the building gypsum powder prepared by using the citric acid gypsum raw material obtained in the present application i...

Embodiment 2

[0038] Example 2: Calcium hydrogen citrate (by-product of Shandong Taihe Biochemical Co., Ltd.) and water were mixed at a mass ratio of 1:6, the stirring speed was 100r / min, the temperature was 20°C, salt gypsum seeds were added, and the median diameter was 62μm, the mass ratio of salt gypsum seed crystals to calcium hydrogen citrate is 1:10, prepare a 0.1mol / L sulfuric acid solution and drop it in at a rate of 5mL / s, continue to stir for 5min after the reaction is complete, then let it stand for 90min, and finally use Wash twice and dry at 40°C. The median diameter of citrate gypsum particles prepared under this condition is 85 μm, and the crystal morphology is very regular, such as Figure 6-7 . Referring to the process for preparing building gypsum powder from citric acid gypsum in patent CN 102249577 A, the 2h flexural strength of the building gypsum powder prepared by using the citric acid gypsum raw material prepared in this application is 3.4MPa, and the 2h compressive...

Embodiment 3

[0039] Example 3: Mix calcium hydrogen citrate (by-product of Weifang Yingxuan Industrial Co., Ltd.) with water at a mass ratio of 1:12, the stirring speed is 500r / min, the temperature is 80°C, and lactic acid bacteria gypsum seeds are added. The median diameter is 80 μm, the mass ratio of salt gypsum seed crystals to calcium hydrogen citrate is 1:6, prepare 10mol / L sulfuric acid solution and drop it in at a speed of 0.008mL / s. Wash 3 times and dry at 50°C. The median diameter of citrate gypsum particles prepared under this condition is 102 μm, and the crystal morphology is very regular, such as Figure 8-9 . Referring to the process for preparing building gypsum powder from citric acid gypsum in patent CN 102249577 A, the 2h flexural strength of the building gypsum powder prepared by using the citric acid gypsum raw material prepared in this application is 3.2MPa, and the 2h compressive strength is 6.8MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com