Continuous production equipment of low-irritant plastic particles based on the principle of volume pressure

A plastic particle and stimulating technology, which is applied in the field of continuous production equipment for low-irritant plastic particles, can solve the problems of cutting and separation of particles that cannot be extruded, unable to guarantee the length and shape of particles, and large differences in the uniformity of output particles. , to achieve the effect of fast cutting and driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

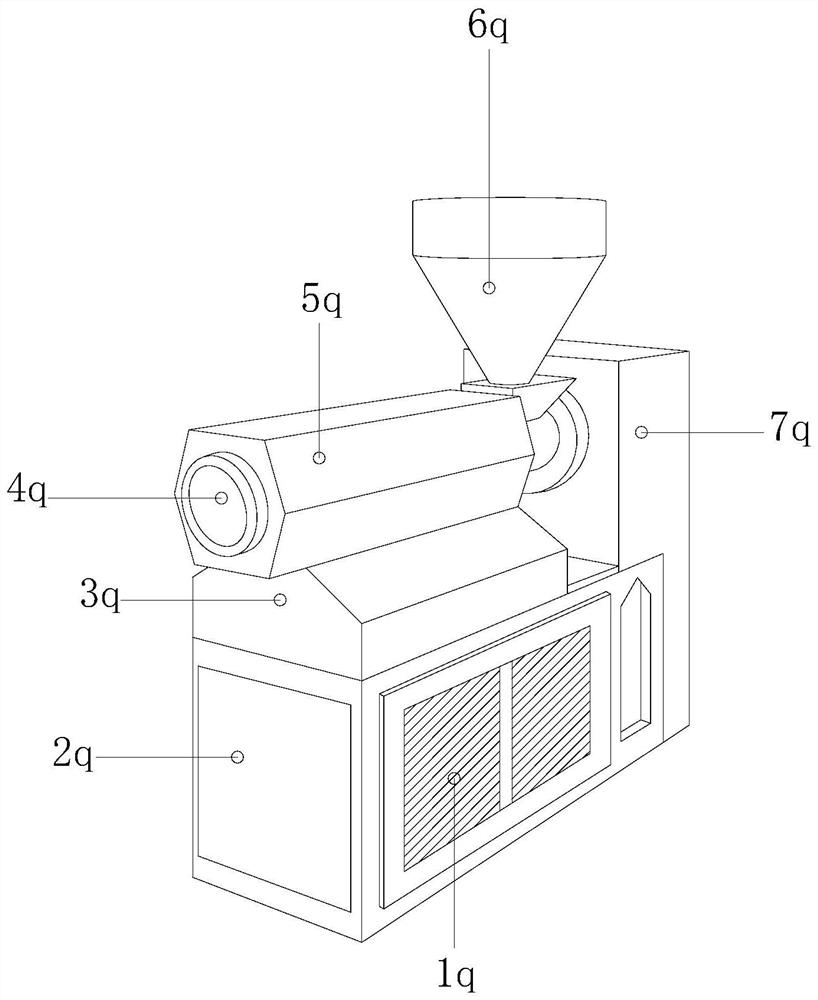

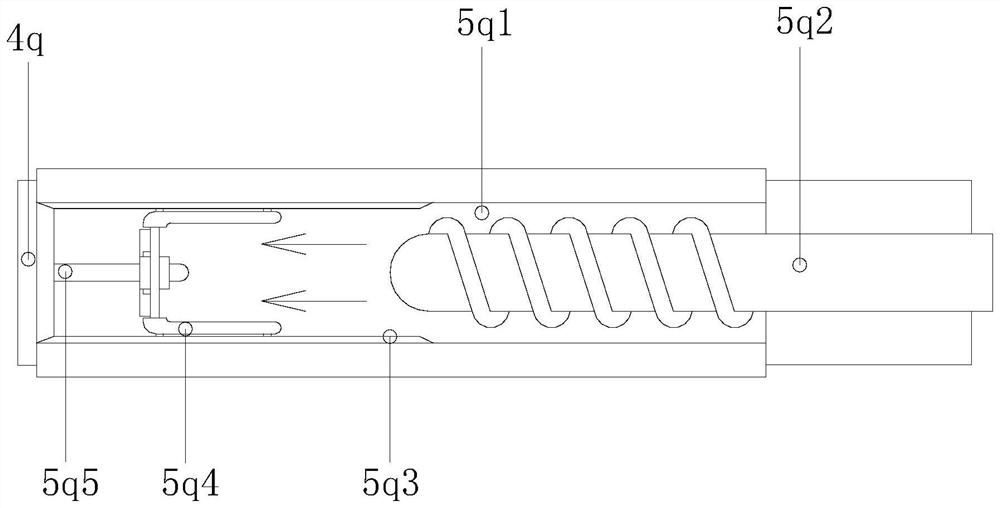

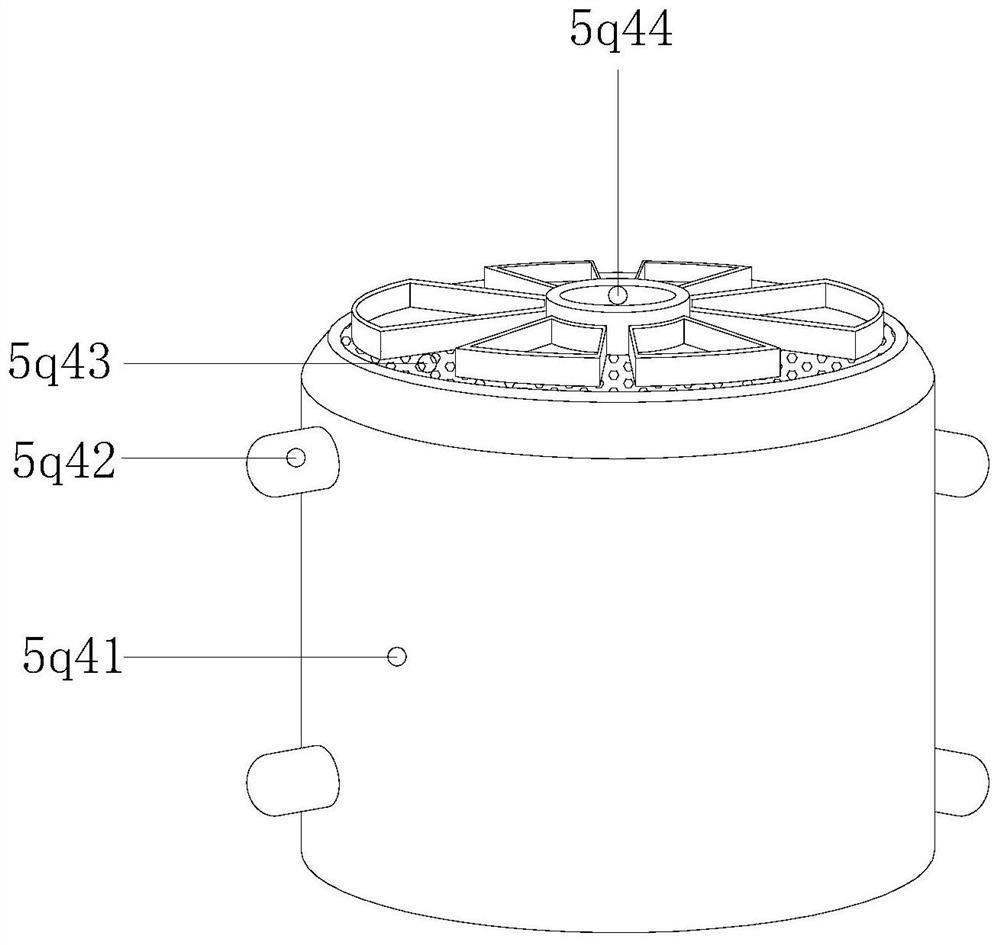

[0028] See Figure 1 - Figure 6 The present invention provides a continuous production apparatus of low irritating plastic particles based on intensive compression principles, including thermofors 1Q, host cabinet 2Q, positioning platform 3Q, discharge port 4Q, processing warehouse 5Q, funnel 6Q, electric power The driver box 7q, the positioning platform 3Q is attached to the top of the main chassis 2Q via an embedded manner, the main chassis 2Q rear end and the power driver box 7Q, the power driver box 7Q upper end and the processing warehouse 5Q rear end Connecting, the processing warehouse 5Q is fitted to the upper end of the positioning platform 3Q, the outlet port 4Q is disposed at the front end of the processing bin 5q, the top of the rear end of the processing bin 5Q is provided with a funnel 6Q, and the interior is connected, said The heat dissipation port 1q is a rectangular structure, and is mounted on the right side of the main base cabinet 2Q by embedding, and the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com