Raw material processing device for making plant wine

A raw material processing and plant technology, which is applied in the field of raw material processing devices for plant wine brewing, can solve the problems of uneven crushing, inability to crush crushing treatment, slow crushing efficiency, etc., and achieve uniform mixing and stirring, good crushing effect, and high mixing efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

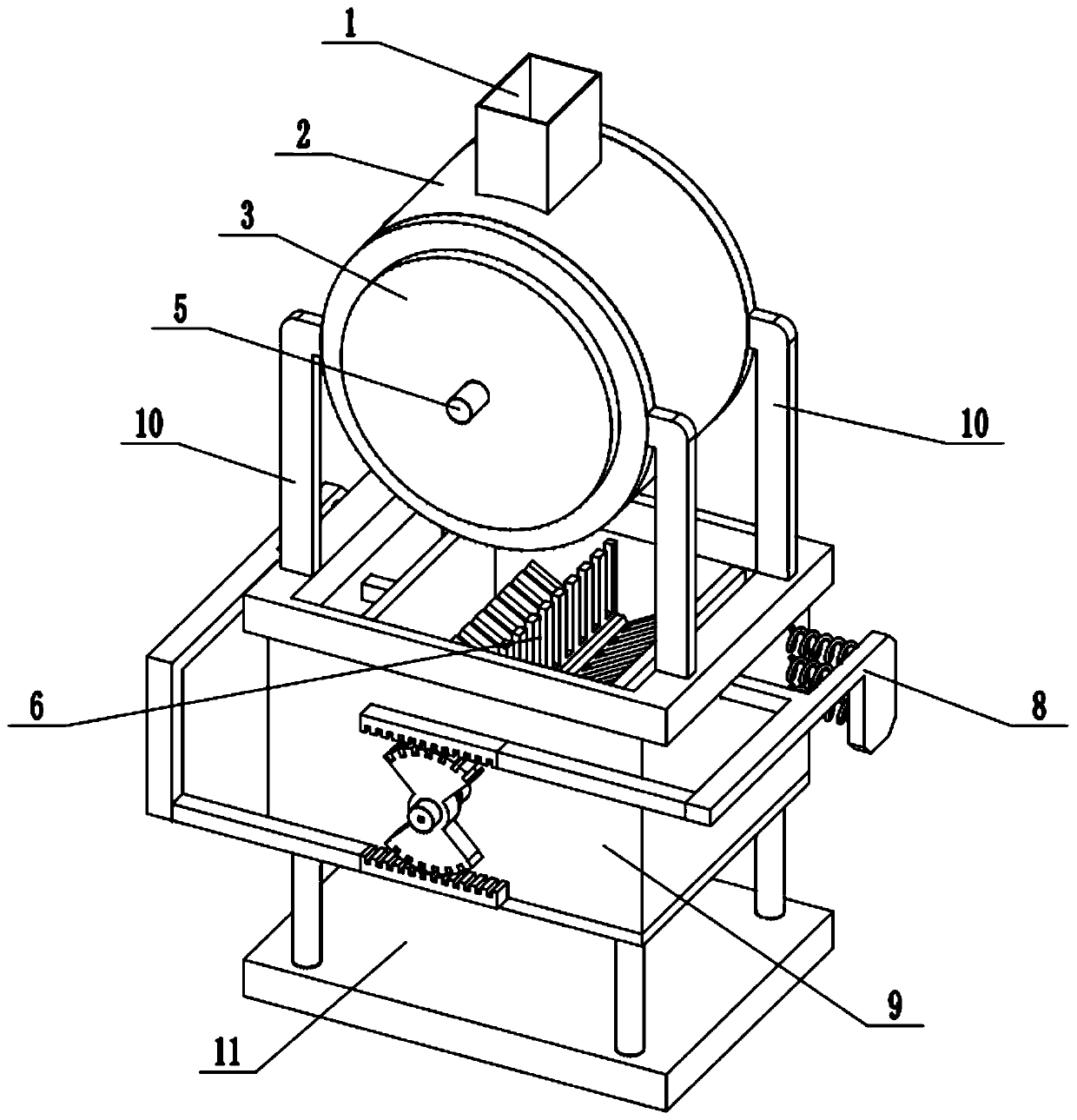

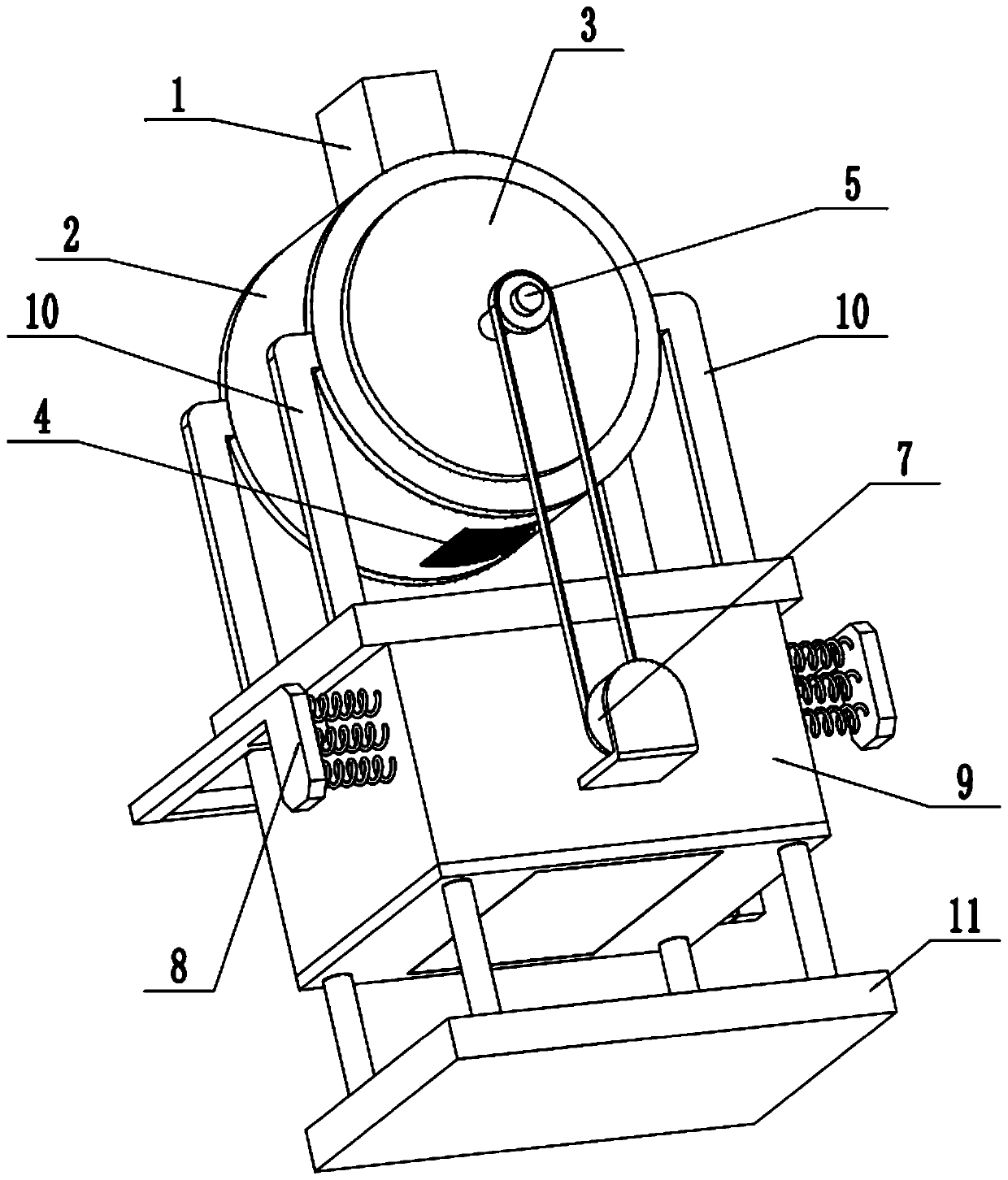

[0032] Such as Figure 1-12 As shown, the raw material processing device for plant wine brewing includes a feed pipe 1, a processing cylinder 2, an end cover 3, a filter plate 4, a milling mechanism 5, a mixing mechanism 6, a driving mechanism 7, a reciprocating pushing mechanism 8, Mixing box 9, side support 10 and support 11, the feed pipe 1 is fixed on the top of the processing cylinder 2; the front and rear ends of the processing cylinder 2 are respectively fixedly connected to an end cover 3; the left and right sides of the processing cylinder 2 The two ends are respectively fixed on the mixing box 9 through two side brackets 10; the front and rear ends of the milling mechanism 5 are respectively rotatably connected to an end cover 3, and the middle part of the milling mechanism 5 is rotatably connected to the processing cylinder 2 The driving mechanism 7 is fixed on the rear end of the mixing box 9, and the driving mechanism 7 is connected to the milling mechanism 5 and ...

Embodiment 2

[0034] Such as Figure 1-12 As shown, the drive mechanism 7 includes a servo motor 701, a drive shaft 702 and a drive sprocket 703 fixed on the drive shaft 702; the output shaft of the servo motor 701 is connected to the drive shaft 702 through a coupling; the drive shaft 702 is drivingly connected to the mixing mechanism 6; the drive sprocket 703 is connected to the grinding mechanism 5 through a chain transmission. Servomotor 701 can drive drive shaft 702 and the drive sprocket 703 that is fixed on the drive shaft 702 to rotate after opening, and drive shaft 702 drives the mixing mechanism 6 to work when drive shaft 702 rotates; Grinding mechanism 5 works.

Embodiment 3

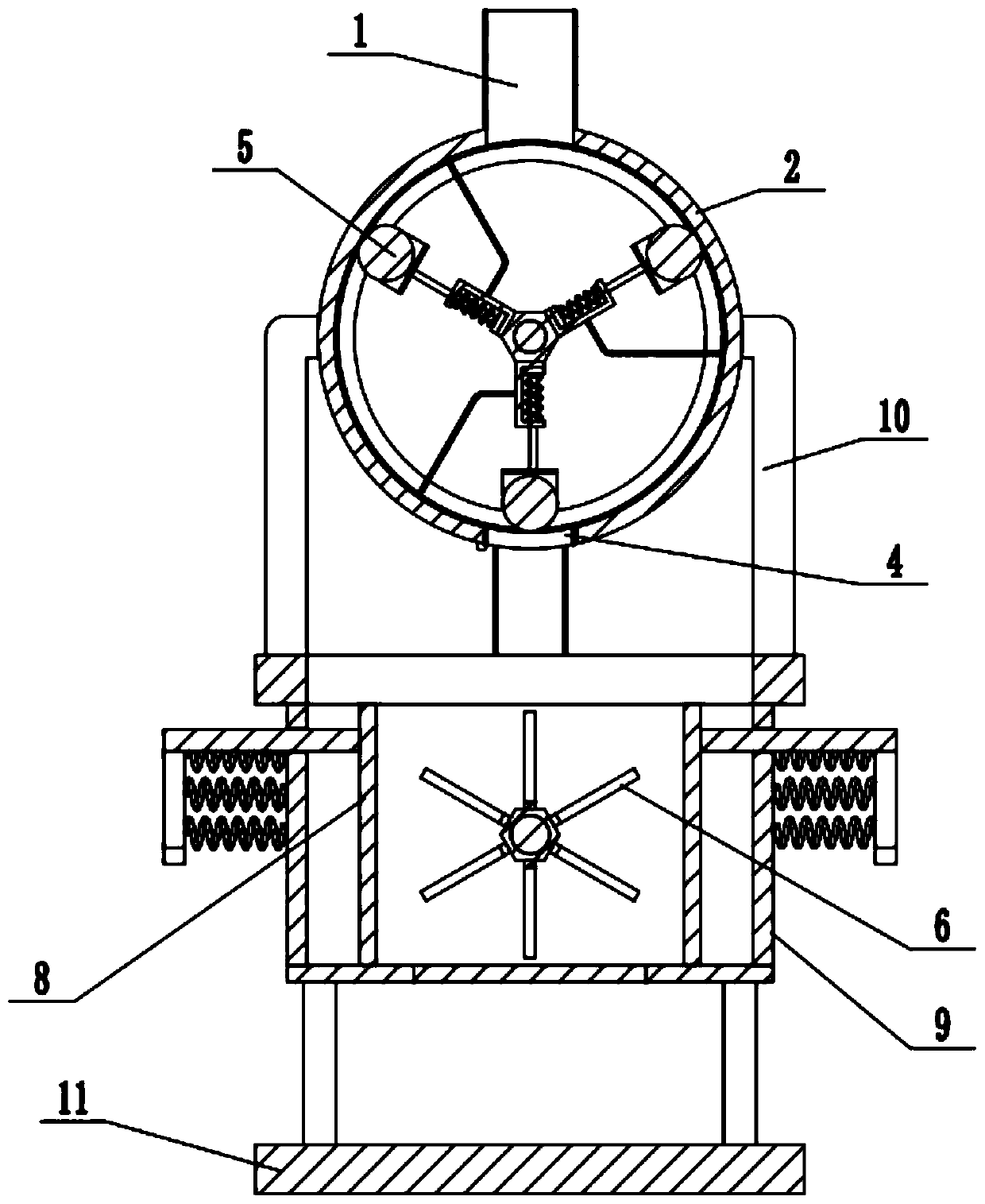

[0036] Such as Figure 1-12 As shown, the grinding mechanism 5 includes a driven sprocket 501, a rotating shaft 502, a rotating tube 503, a rotating arm 504 and a grinding roller 505; the driving sprocket 703 is connected to the driven sprocket 501 through a chain transmission; the driven chain The wheel 501 is fixed on the rear end of the rotating shaft 502, and the front and rear ends of the rotating shaft 502 are rotatably connected to the two end caps 3 respectively, and the middle part of the rotating shaft 502 is fixedly connected to the rotating tube 503, and the rotating tube 503 is rotatably fitted in the processing cylinder 2; The outer end of the rotating tube 503 evenly surrounds and fixedly connects the inner ends of the three rotating arms 504 , and the outer ends of the three rotating arms 504 are respectively rotatingly connected with a grinding roller 505 , and the grinding roller 505 rolls and fits on the inner wall of the processing cylinder 2 . The driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com