Fuel cell stack with central manifold

A fuel cell stack and manifold technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as increased costs, and achieve the effects of saving production costs, saving space, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

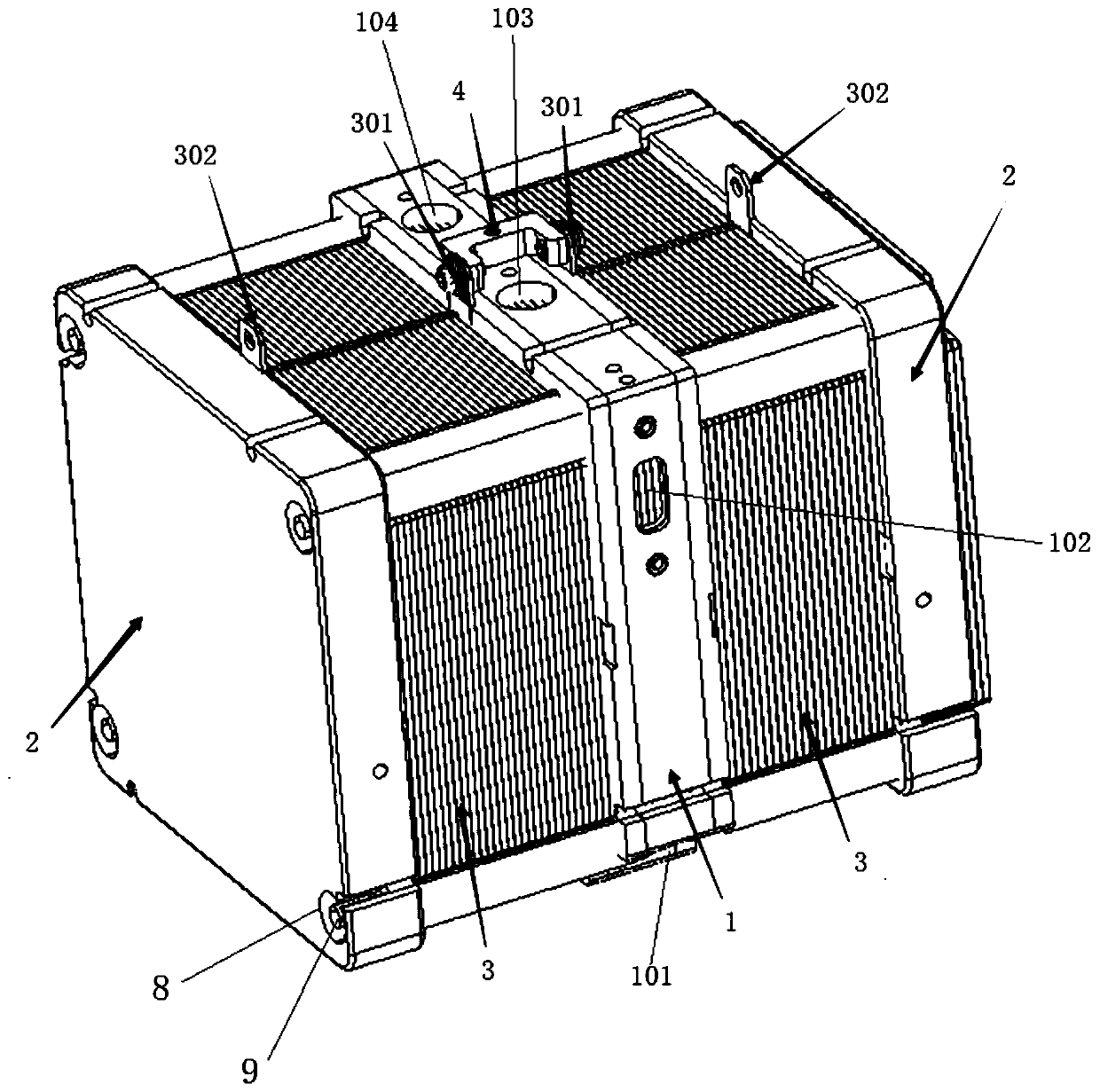

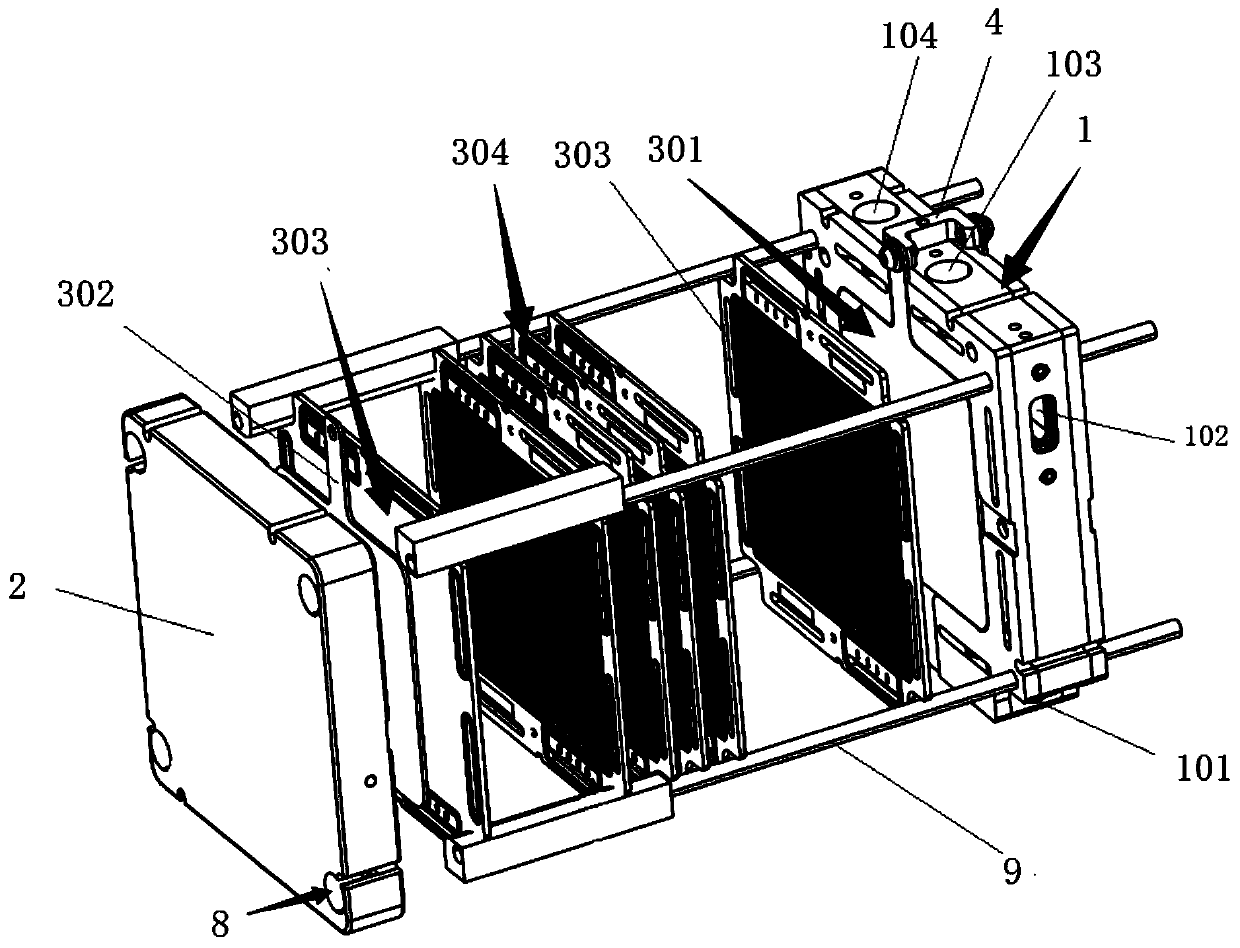

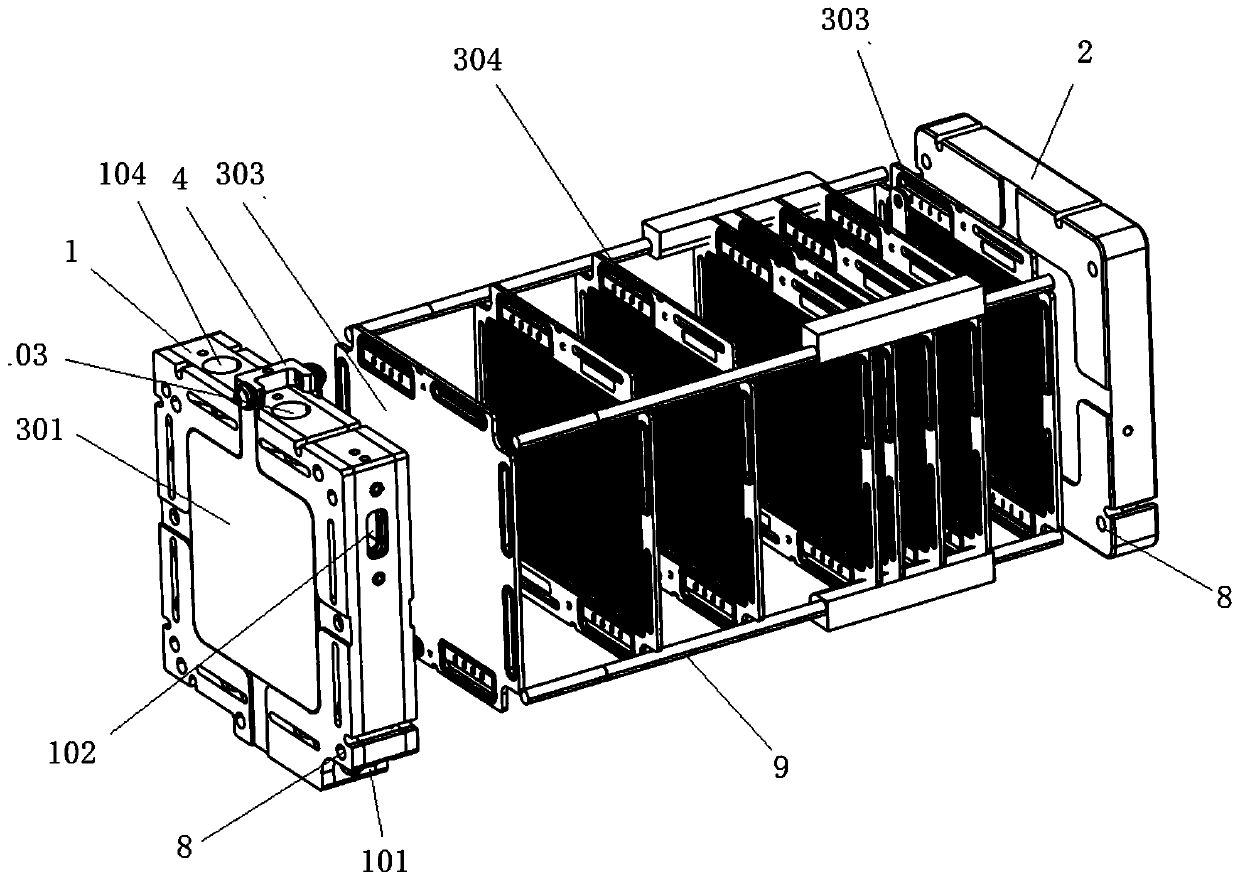

[0049] Embodiment: combine below Figure 1~Figure 8 A specific implementation of the fuel cell stack with a central manifold provided by the present invention is described in detail as follows:

[0050] first as figure 1 As shown, it has a central manifold 1, end plates 2 arranged on both sides of the central manifold 1, and a fuel cell stack 3 fixed between the central manifold 1 and each end plate 2, and the two fuel cell stacks 3 share The central manifold 1 is connected in series; in this embodiment, the power of the two fuel cell stacks 3 on both sides is 500W, and the stack power after series connection is 1000W.

[0051] further combined figure 2 and image 3 As shown, the fuel cell stacks 3 on both sides are structurally symmetrical, and are composed of a connection collector plate 301 fixed on the central manifold 1, an output collector fixed on the end plate 2 with opposite polarity to the connection collector plate 301 The electrical plate 302 and a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com