Ultrahigh-speed data transmission cable and manufacturing process thereof

A technology for data transmission cables and manufacturing processes, applied in cable/conductor manufacturing, insulated cables, communication cables, etc. The effect of electrical constant, improving product transmission rate, and reducing the outer diameter of cable stranding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

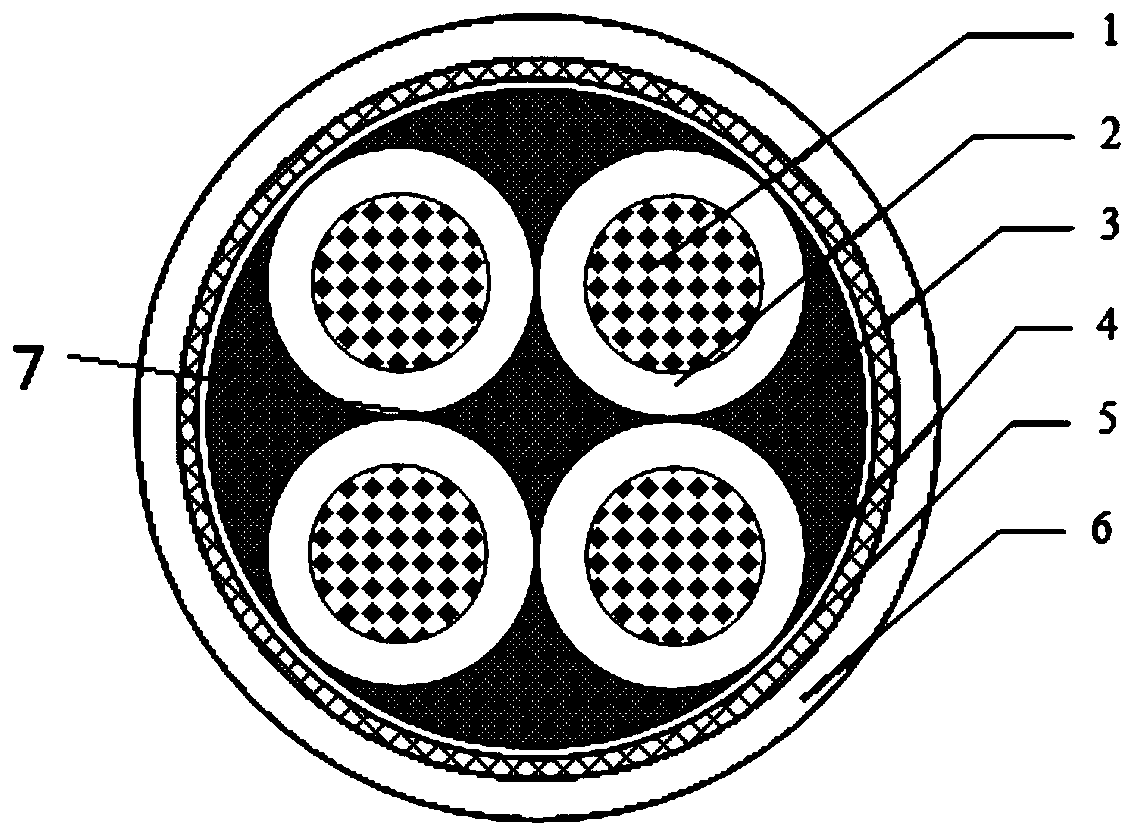

[0034] Such as figure 1 Shown, a kind of ultra-high-speed data transmission cable, comprises the inner conductor 1 of graphene silver-copper alloy, in the inner conductor 1 of graphene silver-copper alloy, three-layer co-extrusion polyperfluoroethylene propylene insulation layer 2, four graphite Graphene silver-copper alloy inner conductors 1 are twisted into cable cores in a star-stranded manner, and microporous polytetrafluoroethylene ropes 7 are arranged in the middle of the four graphene silver-copper alloy inner conductors 1, and vacuum microstructures are added during the star-stranded process. Hole PTFE with filling layer 3, braided with silver-plated copper-clad steel flat wire braid 4 on the outside of the cable core, braided with silver-plated copper-clad nickel round wire braided outside of the silver-plated copper-clad steel flat wire braid 4 Layer 5, an outer sheath 6 of radiation cross-linked ethylene tetrafluoroethylene is extruded outside the braided layer 5 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com