Coating friction and wear performance test method equivalent to engine bench test assessment

An engine bench, friction and wear technology, applied in the direction of testing wear resistance, etc., can solve the problems of little reference value, can not reflect the service conditions of the engine turbine pump dynamic seal, etc., to improve the development efficiency, high reliable service and repeatability The effect of using performance, increasing development reliability and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for testing the friction and wear performance of a coating that is equivalent to an engine short-range bench test test under severe wear conditions with a high PV value includes the following steps.

[0057] (1) The friction and wear test is carried out by the start-stop assessment method under the condition of high PV value in a short period of time

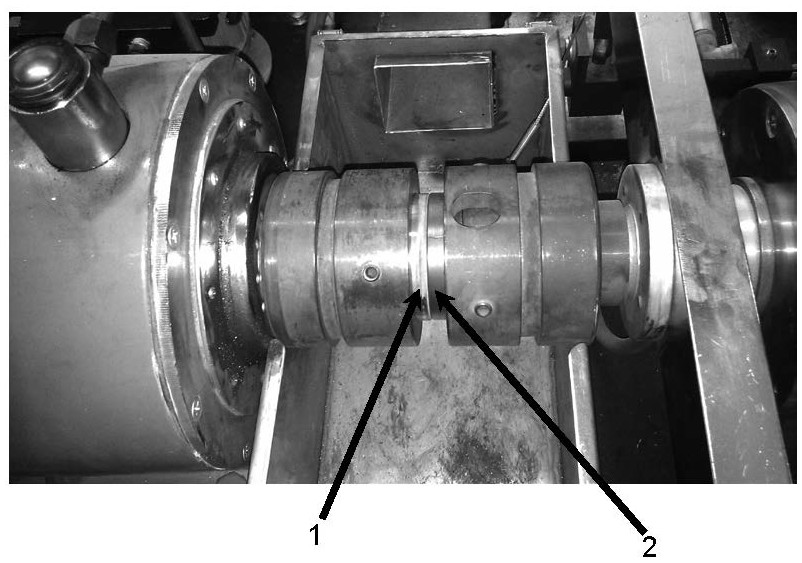

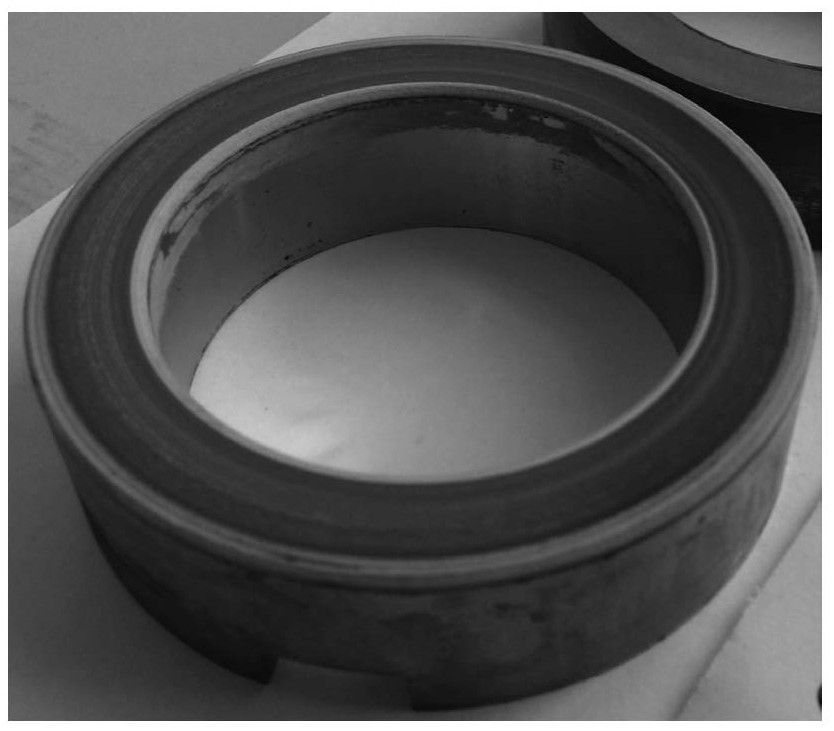

[0058] Use the start-stop assessment friction and wear testing machine to investigate the friction and wear performance of the coating friction pair (moving ring 1 / static ring 2) (see figure 1 ), spraying deposited Al on the surface of the moving ring 2 o 3 coated, the stationary ring is made of copper alloy (see figure 2 ). Here the base material of the moving ring is stainless steel, and the size of the moving ring and the static ring are the same: outer diameter Φ 外 =75mm, inner diameter Φ 内 =53mm, thickness h=20mm. figure 1 The testing machine shown is used for the start-stop evaluation friction and we...

Embodiment 2

[0063] A method for testing the friction and wear performance of a coating that is equivalent to an engine short-range bench test test under severe wear conditions with a high PV value includes the following steps.

[0064] (1) The friction and wear test is carried out by the start-stop assessment method under the condition of high PV value in a short period of time

[0065] The moving ring base material, the size of the moving ring and the size of the static ring are all the same as those in Example 1. The surface of the moving ring is sprayed with Al 2 o 3 There are two types of coating and static ring materials: copper alloy and fluorine-containing copper alloy. Before the formal start-stop assessment, Al 2 o 3 Coated moving ring and copper alloy static ring, Al 2 o 3 The running-in friction test between the coating moving ring and the fluorine-containing copper alloy static ring, the two test parameters are consistent, specifically: the speed of the moving ring is 30...

Embodiment 3

[0071] A method for testing the friction and wear performance of a coating that is equivalent to an engine short-range bench test test under severe wear conditions with high PV values includes the following steps.

[0072] (1) The friction and wear test is carried out by the start-stop assessment method under the condition of high PV value in a short period of time

[0073] The moving ring base material, the size of the moving ring and the size of the static ring are all the same as those in Example 1. The surface of the moving ring is sprayed with Al 2 o 3 Coating, static ring material is copper alloy, same as embodiment 2. Before the formal start-stop assessment, the Al 2 o 3 The running-in friction test between the coating moving ring and the copper alloy static ring, the specific parameters are: the speed of the moving ring is 5000rpm, the contact pressure of the friction surface is 0.4MPa, and the moment of inertia is 0.2kg cm s 2 , Disengaged after friction for 3s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com