Probe type high-flux spark plasma sintering equipment

A technology of discharge plasma and sintering equipment, applied in the field of material science, can solve the problems of low efficiency, time-consuming energy consumption, high energy consumption, etc., and achieve the effect of speeding up the research process and improving the preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment is used to illustrate the structure of the probe type indenter provided by the present invention.

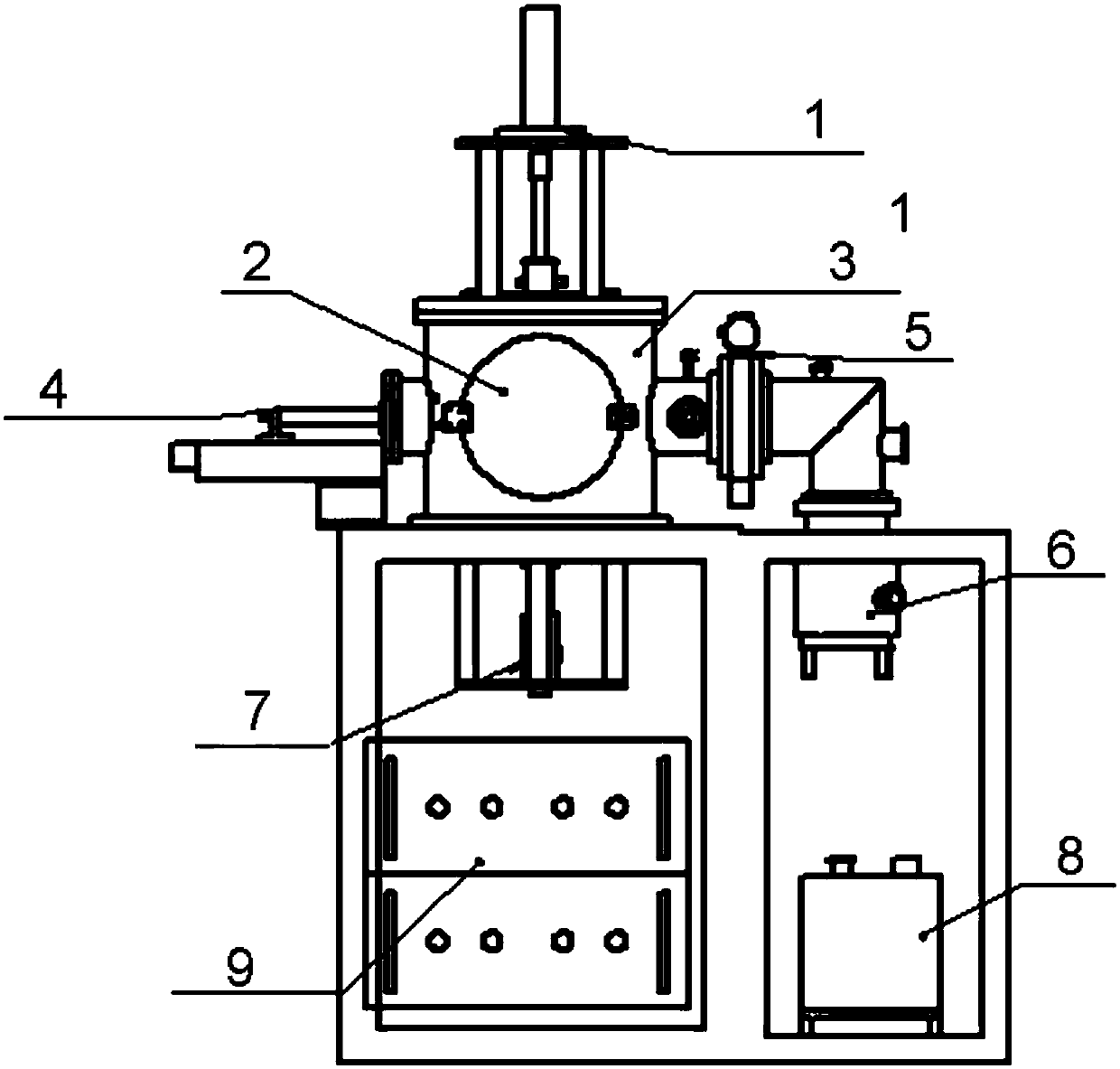

[0055] like figure 1 As shown, the probe type indenter provided by the present invention comprises SPS pressurizing device (1), front door (2), water-cooled vacuum chamber (3), displacement measuring system (4), gate valve (5), molecular pump ( 6), thermocouple lifting mechanism (7), mechanical pump (8), SPS control device (9) and power supply.

[0056] In the pressure system of conventional SPS equipment, the upper graphite column head material used for conducting conductive pressure on the material has limited strength, and cannot heat and pressurize small-diameter samples. The probe-type indenter provided by the invention uses metal tungsten instead of graphite as the indenter material, and its diameter is reduced from 10-20mm to 1mm. At the same time, the tungsten probe type indenter is connected with the lifting device, and the position can be raise...

Embodiment 2

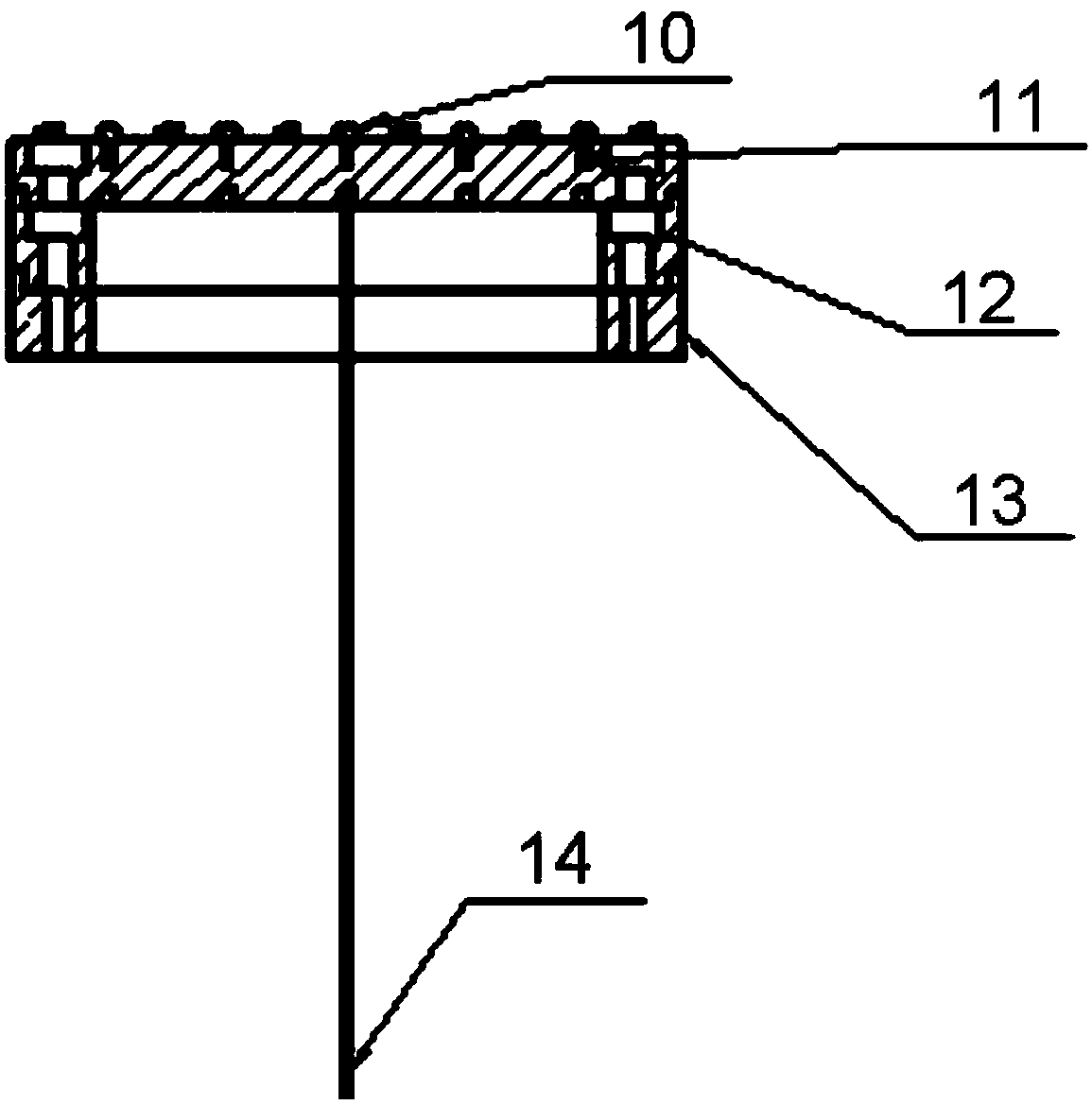

[0058] This embodiment is used to illustrate the structure of the multi-cavity sample tray provided by the present invention.

[0059] like figure 2 As shown, the multi-cavity sample tray provided by the present invention includes a tungsten indenter (10), a graphite sample tray (11), a graphite tray and electrodes (12), an insulating tray (13), and a thermocouple (14). In this embodiment, there are 50 evenly distributed sample grooves on the graphite sample disk, each sample groove has an aperture of 1mm, and each sample groove is matched with a probe-type indenter. The graphite sample plate is placed on the insulating tray, and the graphite tray and electrodes are fixed around it, and the thermocouple passes through the insulating tray from the bottom to connect with the graphite sample plate. Compared with the sintering of a single sample in the graphite mold of the traditional SPS equipment, the graphite mold of this embodiment can place 50 samples with a diameter of 1mm...

Embodiment 3

[0061] This embodiment is used to illustrate the structure of the multi-sample tray moving and positioning system provided by the present invention.

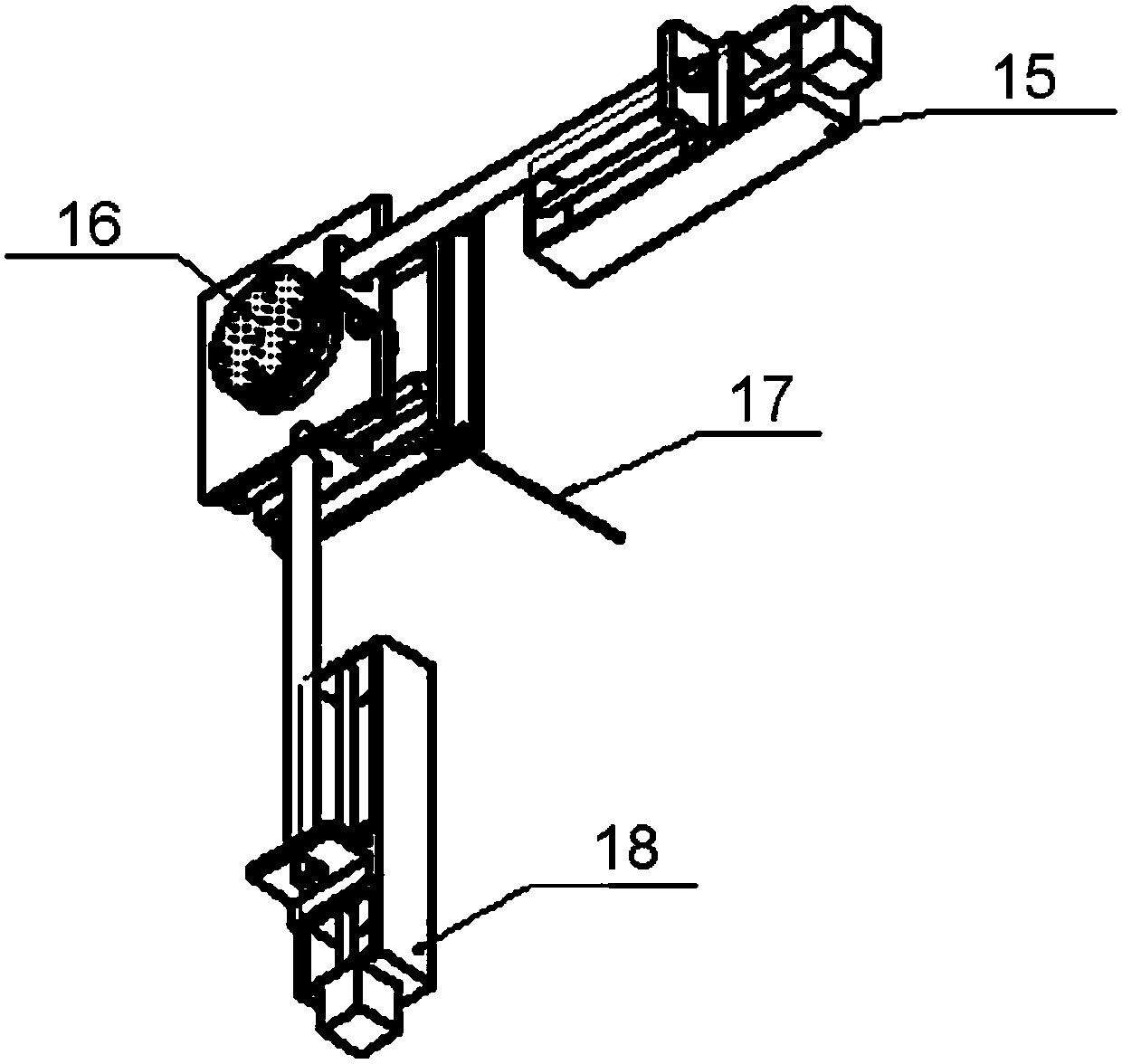

[0062] like image 3 As shown, the multi-sample tray moving positioning system provided by the present invention includes a Y-direction moving motor (15), a sample tray (16), a thermocouple (17) and an X-direction moving motor (18).

[0063] The sample tray positioning system mainly uses two sets of servo motors, the X-direction moving motor (18) and the Y-direction moving motor (15) to accurately control the left and right (X direction) and front and rear (Y direction) displacements of the sample tray respectively. When the samples in each hole are sintered, the position of the graphite mold is accurately moved through the positioning system, so that the metal tungsten column head above the mold and the thermocouple below the mold used to measure and control the temperature of the sample material are in a vertically aligned pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com