a pe tube

A pipe body, No. 1 technology, applied in the direction of pipes, pipe components, rigid pipes, etc., can solve the problems of clogging of PE drainage pipes, scratches on the inner wall of the pipes, and reduced durability of PE drainage pipes, etc. The effect of large flow diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

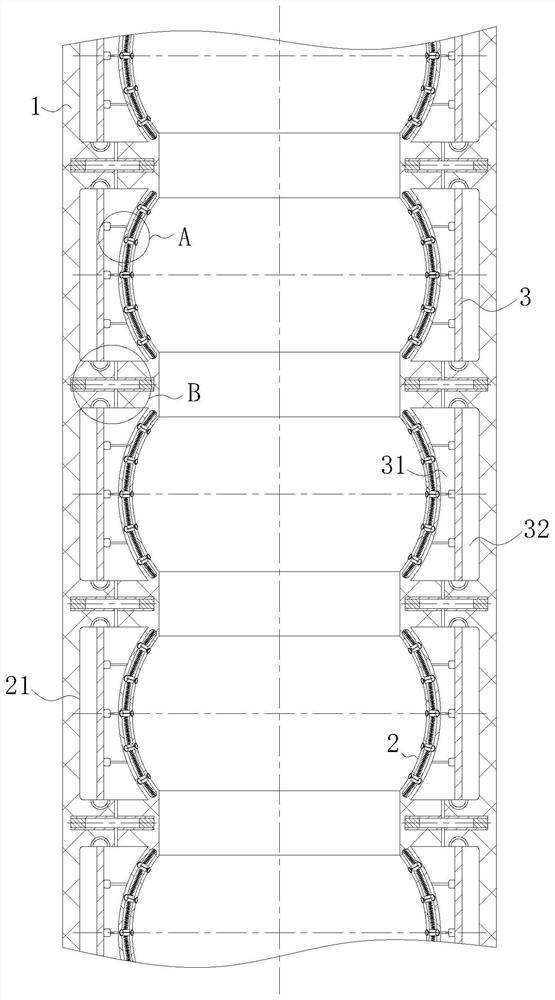

[0019] use Figure 1-Figure 4 A PE pipe according to one embodiment of the present invention will be described below.

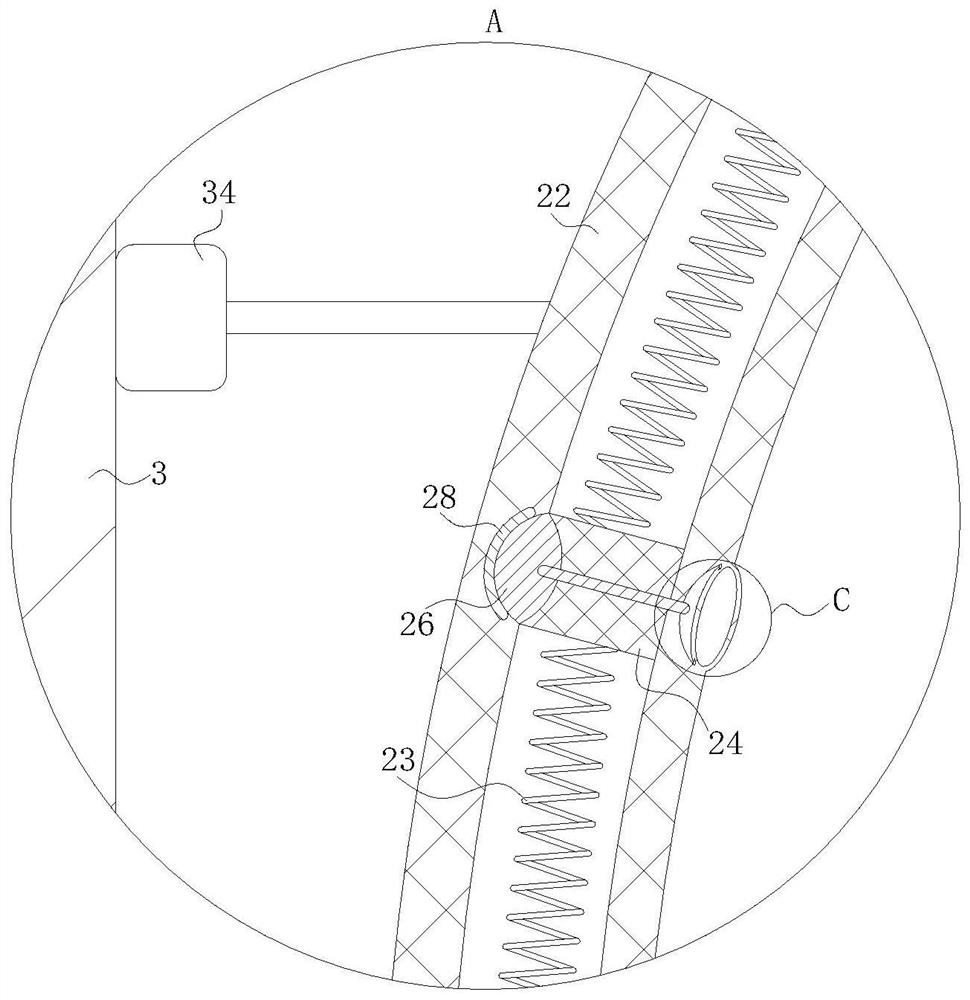

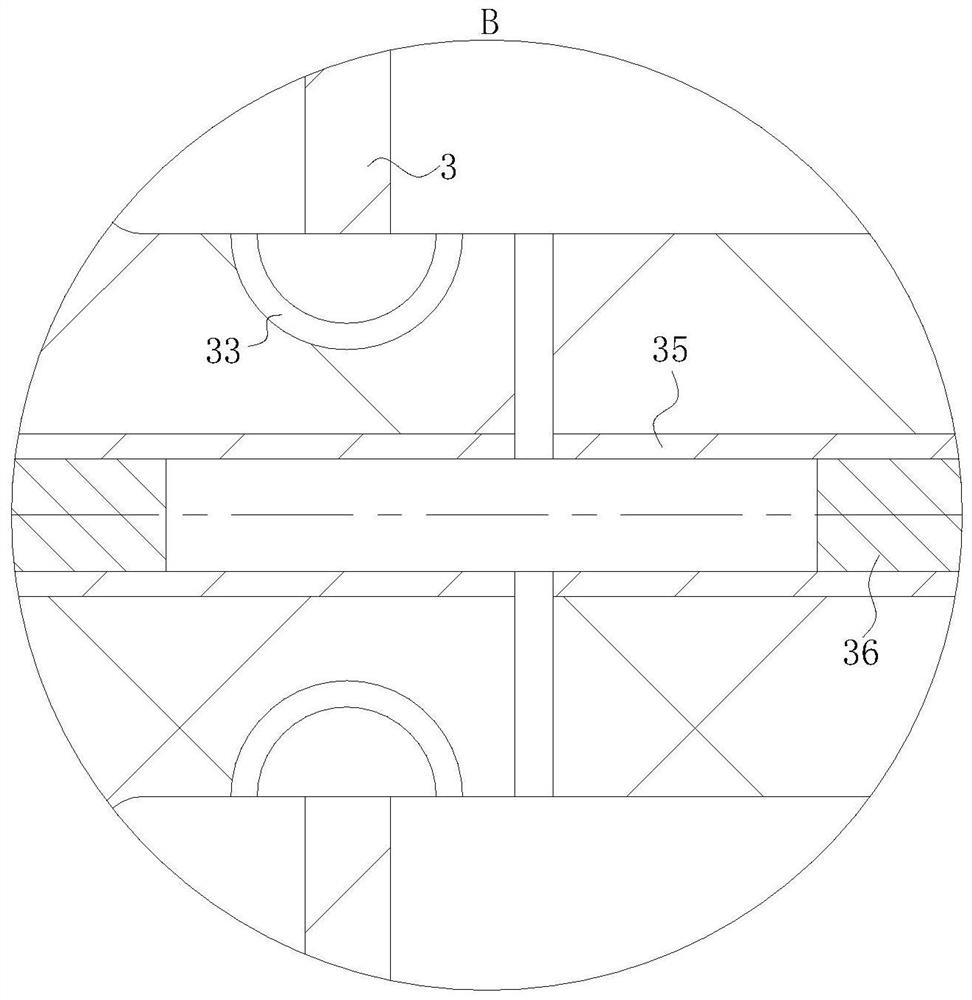

[0020] like Figure 1-Figure 4As shown, a PE pipe according to the present invention includes a pipe body 1 and a rebound mechanism 2; the inside of the pipe body 1 is provided with a rebound mechanism 2; the rebound mechanism 2 includes an extrusion chamber 21, an elastic layer 22, Spring 23 and support rod 24; Said extrusion chamber 21 is evenly opened in the wall of pipe body 1, and the inner side of extrusion chamber 21 is provided with elastic layer 22; Said elastic layer 22 is connected as a whole with the inner wall of pipe body 1, The elastic layer 22 has a certain degree of flexibility, and the inner level of the elastic layer 22 is uniformly fixed with support rods 24; the support rods 24 are connected by springs 23; The water pressure is relatively high, and the wall of the pipe body 1 is evenly opened with an extrusion chamber 21, and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com