Monocoque vaporization fuel economizer and manufacturing method thereof

A fuel-saving, hard-shell technology, applied in chemical instruments and methods, mechanical equipment, machines/engines, etc., can solve the problems of non-separation of negative ion functional materials and far-infrared materials, unreasonable settings, and inconvenient installation. To achieve the effect of reducing surface tension, simple structure and reducing carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A method for preparing a hard-shell carburetion economizer provided according to the present invention, comprising:

[0048]Step 1: After mixing 50-60% PVC pellets, 35-40% ultrafine tourmaline powder, and 15-20% transition metal oxide powder evenly, perform injection molding processing to form the first hard plastic sheet 2 and / or the second Two hard plastic sheets 5;

[0049] Step 2: Weigh 50-60% tourmaline powder, 20-30% transition metal oxide powder, and 20-30% epoxy adhesive according to the formula and evenly mix them into a slurry, and coat 2-4 layers on the non-woven fabric to form The functional layer is air-dried or dried for use; the epoxy adhesive is a liquid adhesive composed of epoxy resin, curing agent, modifier, and diluent;

[0050] Wherein, the ratios are mass ratios.

[0051] The preparation method of the hard shell type vaporization fuel economizer also includes:

[0052] Step 3: For the first paste, apply epoxy adhesive to the groove of the lower ...

Embodiment 1

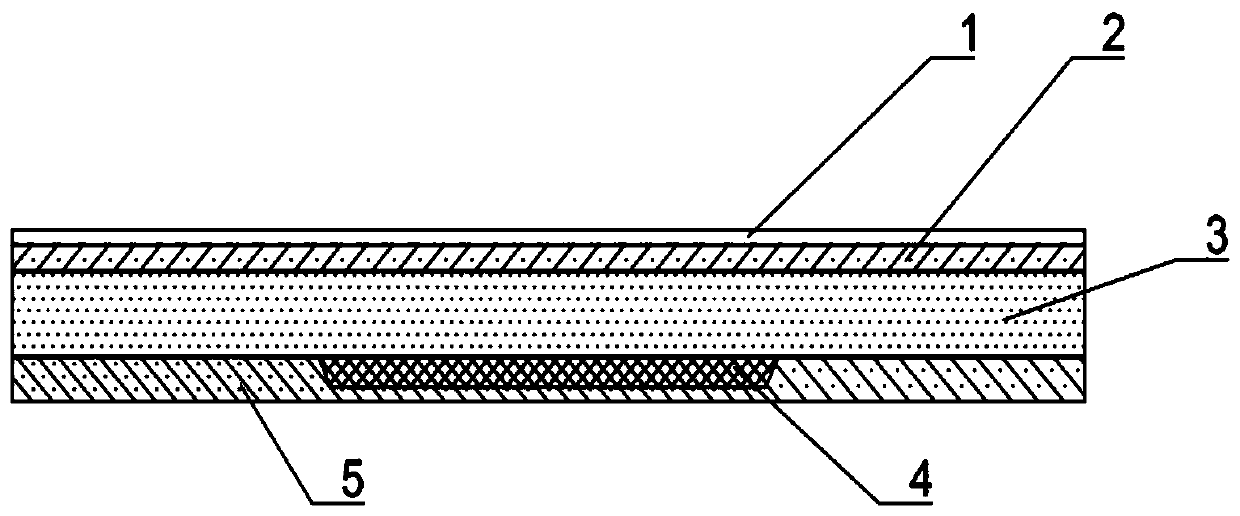

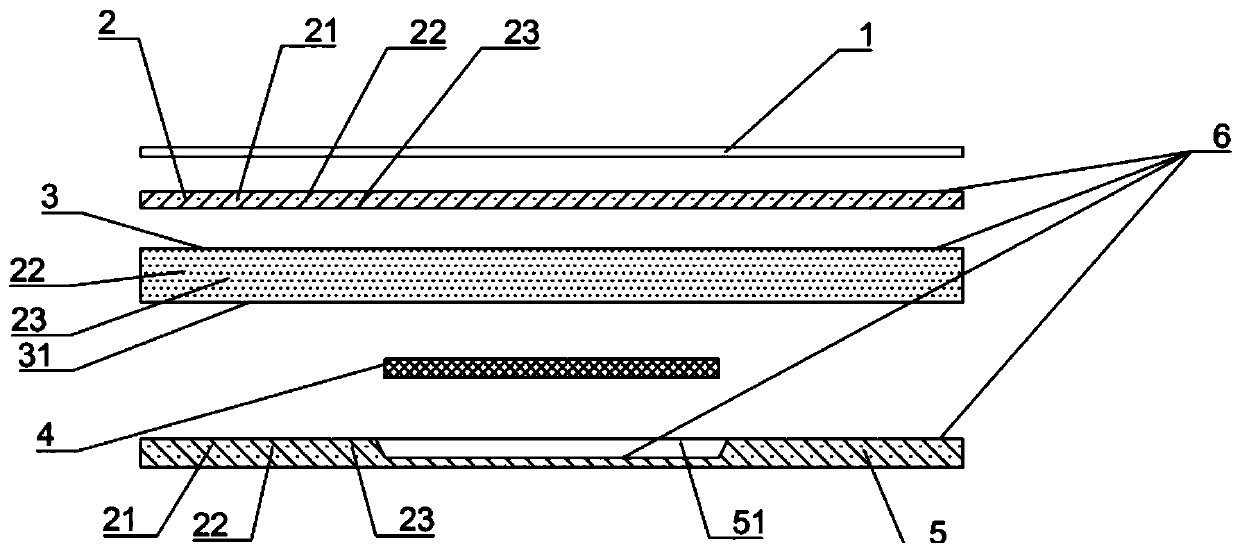

[0058] Embodiment 1 is a preferred example of the basic embodiment, such as figure 1 , figure 2 As shown, its structural relationship is as follows:

[0059] A kind of hard card type carburetor, which consists of a plastic sticker, that is, sticker 1, an upper hard plastic sheet, that is, the first hard plastic sheet 2, a functional layer 3, a permanent magnet sheet, that is, a magnetic sheet 4, and a lower hard plastic sheet, that is, The second hard plastic sheet 5 is composed of; the upper hard plastic sheet and the lower hard plastic sheet are made of PVC material, that is, polyvinyl chloride 21, ultrafine tourmaline powder 22, and transition metal oxide powder 23 are mixed and then injection molded; the lower hard plastic sheet A groove 51 is provided at the center of the sheet to receive the permanent magnet sheet; the functional layer 3 is made of ultrafine tourmaline powder 22 and transition metal oxide powder 23 with epoxy adhesive, that is, adhesive 6 mixed and ble...

Embodiment 2

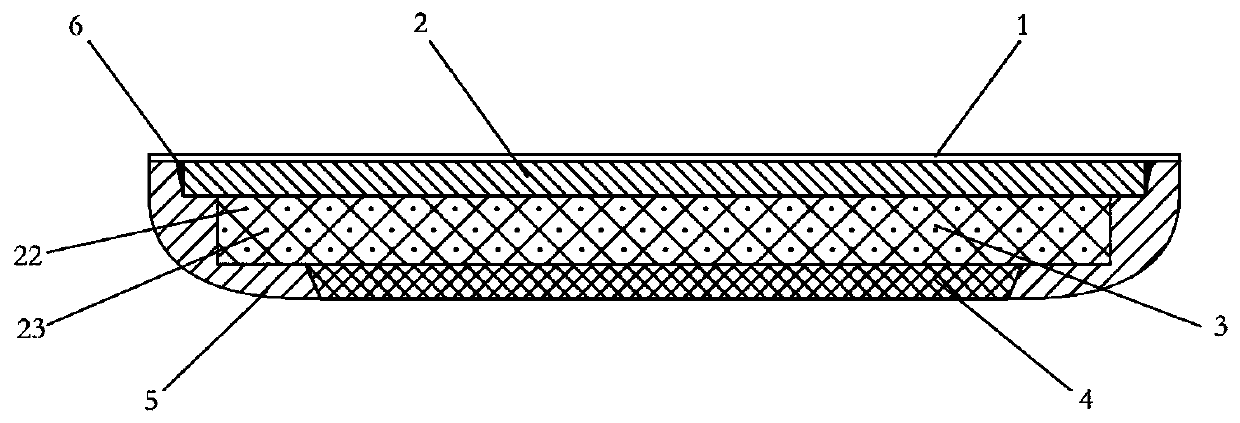

[0081] Embodiment 2 is a preferred example of the basic embodiment, such as image 3 As shown, its structural relationship is as follows:

[0082]Box-shaped carburetor, including label sticker, that is, sticker 1, tourmaline plaster, that is, functional layer 3, magnetic sheet 4, ABS lower shell, that is, the second hard plastic sheet 5, ABS glue, that is, adhesive 6, ABS upper The cover is the first hard plastic sheet 2, wherein: the magnetic sheet 4 is inlaid in the ABS lower shell, and the magnetic sheet 4 is made into an inverted trapezoid, which will not fall out from the ABS lower shell. The lower shell is connected; the tourmaline plaster body is placed in the ABS lower shell, and the tourmaline plaster body is made of tourmaline powder, transition metal and ABS glue. The top surface of the body is in contact with the ABS upper cover; the ABS upper cover is placed on the step of the ABS lower shell, and the side where the ABS lower shell contacts the ABS upper cover ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com