Titanium-silicon molecular sieve, preparation method and application thereof, and propylene epoxidation method

A technology of titanium-silicon molecular sieve and propylene, which is applied in the field of molecular sieves, can solve problems such as poor catalytic effect, achieve the effects of improving selectivity, low price, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

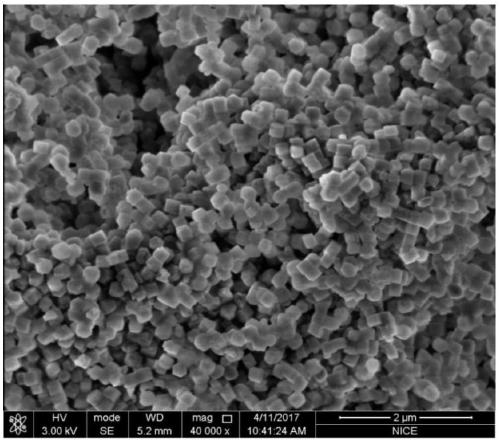

[0028] According to a preferred embodiment of the present invention, a:c is in the range of 4-10:1, and b:c is in the range of 2-3:1.

[0029] According to a most preferred embodiment of the present invention, the thickness of the crystal grains of the titanium-silicon molecular sieve is 600-1200 nm, a:c is in the range of 4-10:1, and b:c is in the range of 2-3:1. The titanium-silicon molecular sieve grains of this preferred embodiment are not only thinner but also smaller in size, and when used in the propylene epoxidation process, have higher catalytic activity and selectivity of target products.

[0030] According to the titanium silicon molecular sieve of the present invention, preferably, the molar ratio of silicon element: titanium element is 1: (0.01-0.5), more preferably silicon element: the molar ratio of titanium element is 1: (0.01-0.3), most preferably 1: (0.01-0.03). In the present invention, X-ray fluorescence spectrometry (XRF) is used to measure the content of...

specific Embodiment approach

[0046] According to a specific embodiment of the present invention, the method further includes filtering and washing after hydrothermal crystallization to obtain the solid product described in step (2). The solid is dried or not dried and then calcined, preferably dried and then calcined.

[0047] According to a specific embodiment of the present invention, the drying conditions include: a temperature of 80-150° C., preferably 100-120° C., and a time of 4-24 hours, preferably 10-16 hours.

[0048] According to the method provided by the present invention, preferably, the roasting conditions include: a temperature of 400-700° C., preferably 500-650° C., and a time of 1-8 hours, preferably 3-6 hours.

[0049] The third aspect of the present invention provides the titanium-silicon molecular sieve prepared by the above-mentioned preparation method. The grains of the titanium-silicon molecular sieve obtained by the above preparation method are plate-shaped, and the thickness of t...

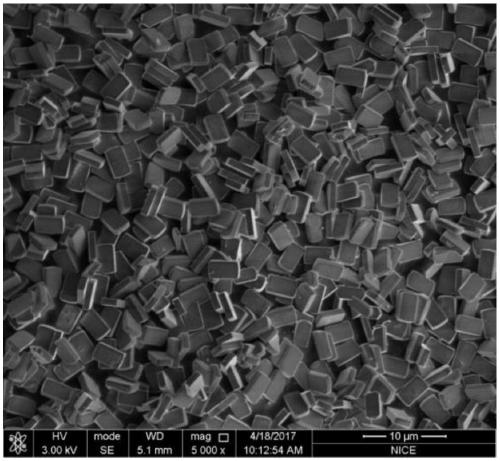

Embodiment 1

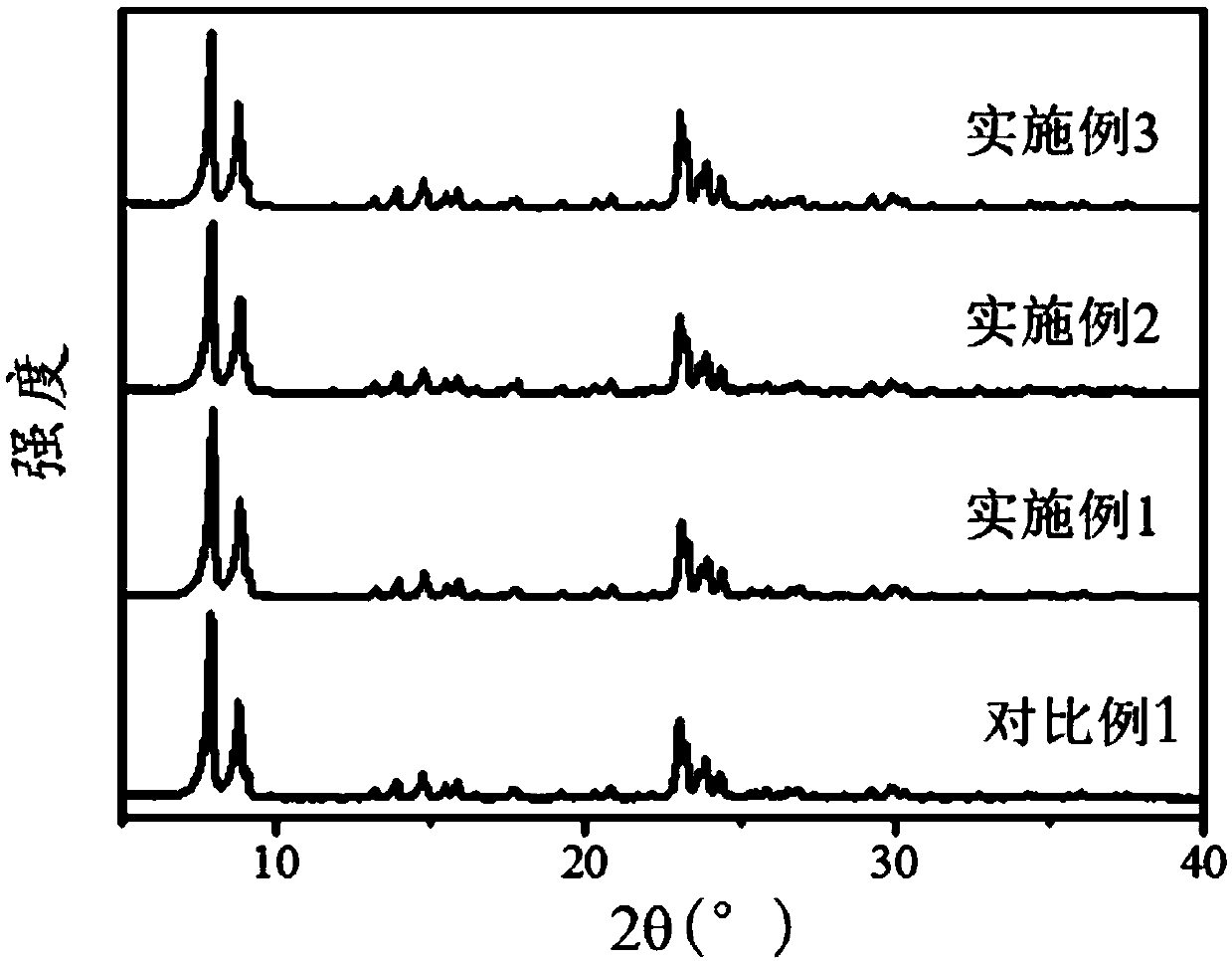

[0059] Put 30g of deionized water into the pressure vessel, then mix 10.4g of ethyl orthosilicate, 2g of tetrapropylammonium bromide and 10g of urea evenly, stir at room temperature (25°C) for 0.5h, and then Add 2.4g of titanium sulfate, and mix uniformly to obtain a mixture (pH value of 9.3). Place it in a closed stainless steel reaction kettle, and keep it under autogenous pressure at 200°C for 20h. The sample was taken out, filtered and washed, dried at 120°C for 12 hours, and calcined at 550°C for 5 hours to obtain TS-1 molecular sieve powder, which was named T-1. The molecular sieve was analyzed by XRF, SEM and XRD, and the titanium and silicon elements are listed in Table 1. SEM picture as figure 1 shown, from figure 1 It can be seen from the figure that the grain size is relatively uniform, and it is plate-shaped. The thickness of the grain and the values of a:c and b:c are listed in Table 1. XRD spectrum as image 3 shown, from image 3 It can be seen that the T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com