A Continuous Ink Cartridge Ink Filling System Based on Oily Ink

An oil-based ink and pot channel technology, applied in printing and other fields, can solve problems such as interference with printing results, inconvenient removal of water stains, and the fragility of wet paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

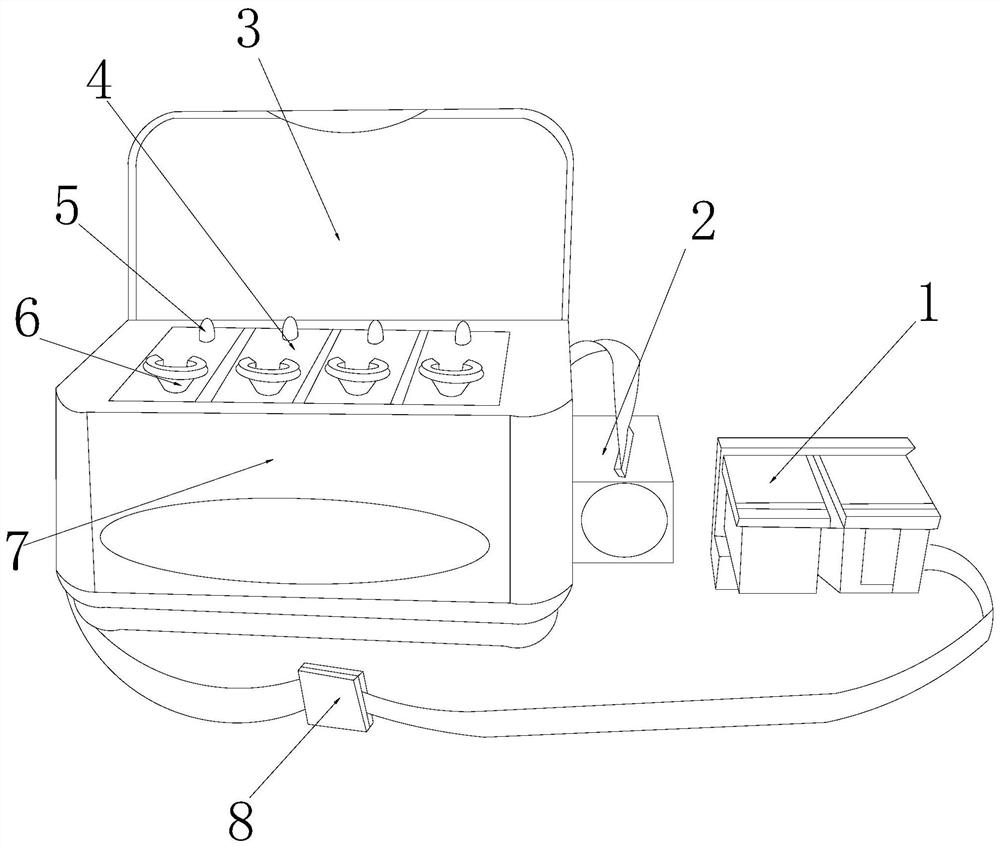

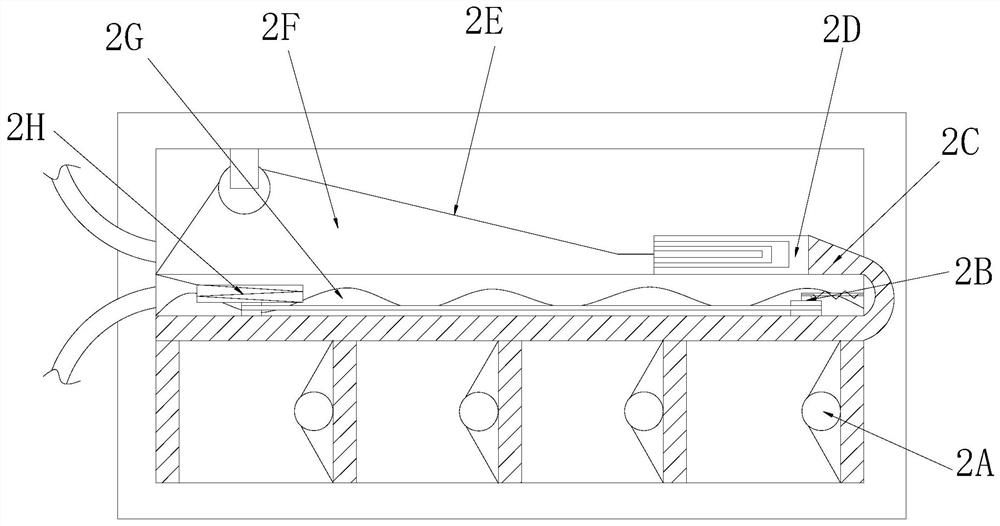

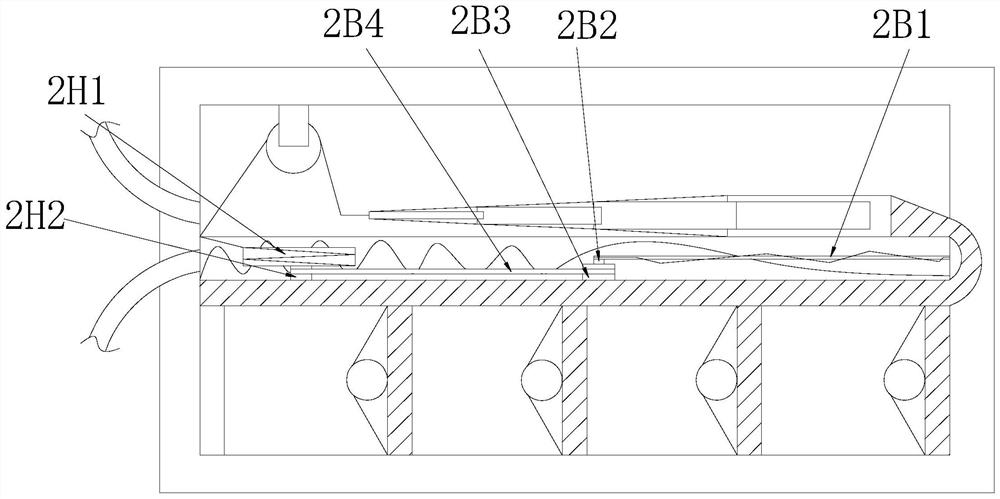

[0031] see Figure 1-Figure 7, the present invention provides an oil-based ink-based tank channel to prevent ink bubble empty spray continuous supply ink cartridge ink system, its structure includes: sub-point nozzle groove 1, display board continuous supply ink cartridge 2, tank cover 3, ink tank pool 4 , ellipsoid plug 5, finger hook cover cap 6, storage box 7, filter element flat tube belt 8, said display board connected to the ink cartridge 2 close to the lower right corner of the storage box 7, said display board connected to the ink cartridge 2 through the filter element flat tube The belt 8 communicates with the sub-nozzle slot 1, the storage box 7 is mechanically connected to the box cover 3 through a hinge, and the ellipsoidal plug 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com