A kind of oil-coal mixing process and its design method and application

A mixing process, oil-coal technology, applied in the direction of mixing methods, petroleum industry, chemical instruments and methods, etc., can solve the problems of uneven mixing of two phases of oil-coal slurry, difficulty in transportation and measurement, easy agglomeration of coal powder, etc., to achieve The effect of short mixing program time, accurate control and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

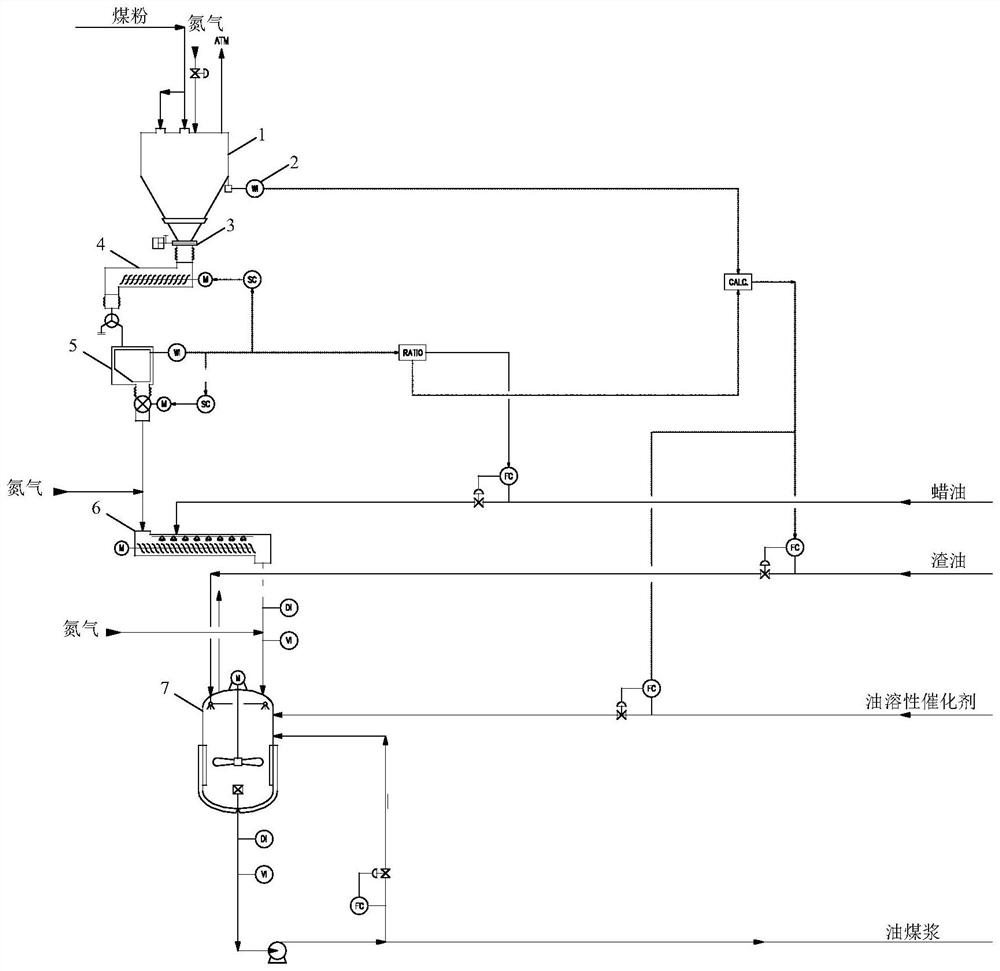

[0034] For further elaborating specific features of the present invention, will combine figure 1 and specific examples are described.

[0035] An oil-coal mixing process, comprising the following processes:

[0036] The pulverized coal from the coal preparation device enters the pulverized coal bin 1, and the residence time in the pulverized coal bin 1 is 2 hours, where the temperature is 80°C, the pressure is a micro positive pressure of ≤80KPa, the normal material level is 60%, and the pulverized coal The particle size is 60-90μm. A measuring instrument 2, a remote oxygen concentration detector and a humidity detector are installed on the pulverized coal bin 1. During the buffering period, the emergency shut-off valve 3 is closed, and the weight of pulverized coal, oxygen concentration and temperature are measured, and the data is transmitted to the computer remotely. The shaft length of the conveyor 4 is 3.5 meters, and the vibration transmission prevents coal dust from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com