Solid oxide ammonia fuel cell

A solid oxide, fuel cell technology, used in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of reduced electrochemical performance, reduced ammonia decomposition performance, etc., to reduce thermal energy loss and improve electricity. Chemical properties, the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

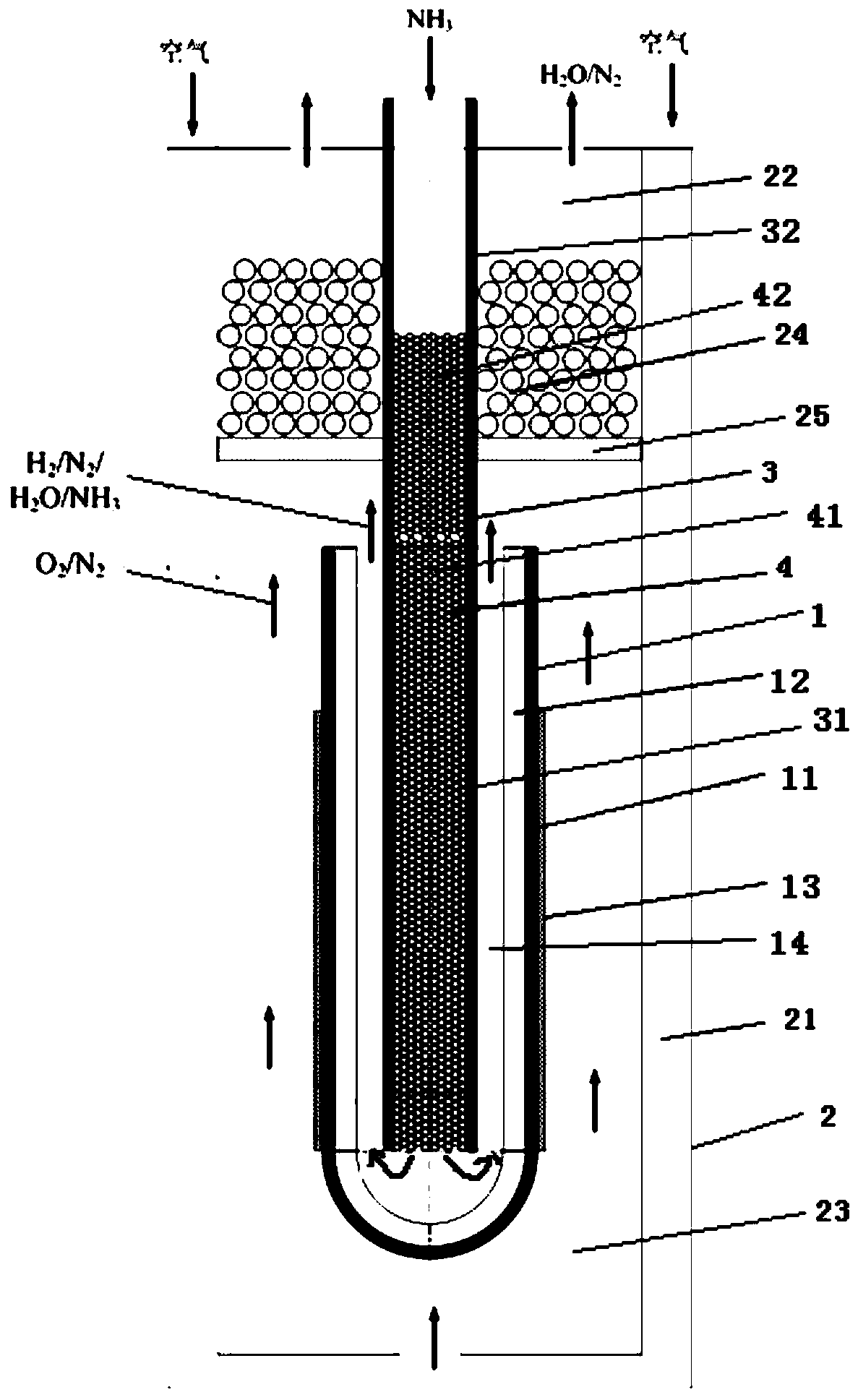

[0056] This embodiment provides a solid oxide ammonia fuel cell, the structure of which is as follows figure 1 as shown,

[0057] including housing 2;

[0058] An ammonia supply pipe 3 is arranged in the housing 2 along the axial direction of the housing 2, and the ammonia supply pipe 3 is filled with an ammonia decomposition catalyst to form an ammonia decomposition catalyst layer 4;

[0059] The fuel cell component 1 includes a tubular battery body with an open end, the battery body has an inner cavity 14 suitable for the ammonia supply pipe 3 to be inserted into the battery body from the open end, along the direction away from the inner cavity 14 Directionally, the battery body sequentially includes an anode layer 12, an electrolyte layer 11 and a cathode layer 13, so that ammonia gas enters the inner cavity 14 from the outlet end of the ammonia supply pipe 3 and contacts the anode layer 12;

[0060] The air channel 21 is arranged in the casing 2 to supply air into the ca...

Embodiment 2

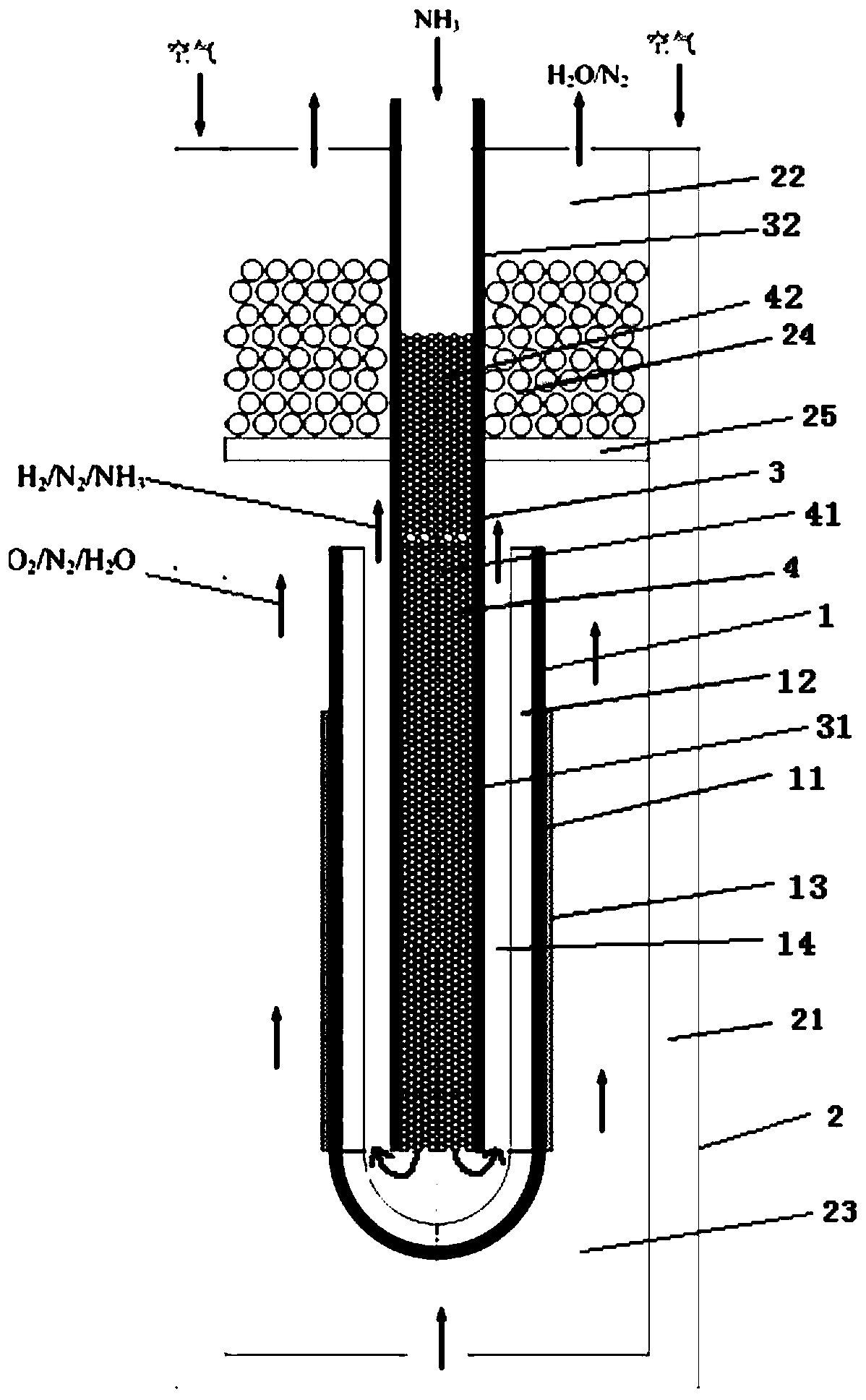

[0071] This embodiment provides a solid oxide ammonia fuel cell, and the difference from Embodiment 1 is that the electrolyte layer used is a proton conductor electrolyte, and the structure is as follows figure 2 as shown,

[0072] including housing 2;

[0073] An ammonia supply pipe 3 is arranged in the housing 2 along the axial direction of the housing 2, and the ammonia supply pipe 3 is filled with an ammonia decomposition catalyst to form an ammonia decomposition catalyst layer 4;

[0074] The fuel cell component 1 includes a tubular battery body with an open end, the battery body has an inner cavity 14 suitable for the ammonia supply pipe 3 to be inserted into the battery body from the open end, along the direction away from the inner cavity 14 Directionally, the battery body sequentially includes an anode layer 12, an electrolyte layer 11 and a cathode layer 13, so that ammonia gas enters the inner cavity 14 from the outlet end of the ammonia supply pipe 3 and contacts...

Embodiment 3

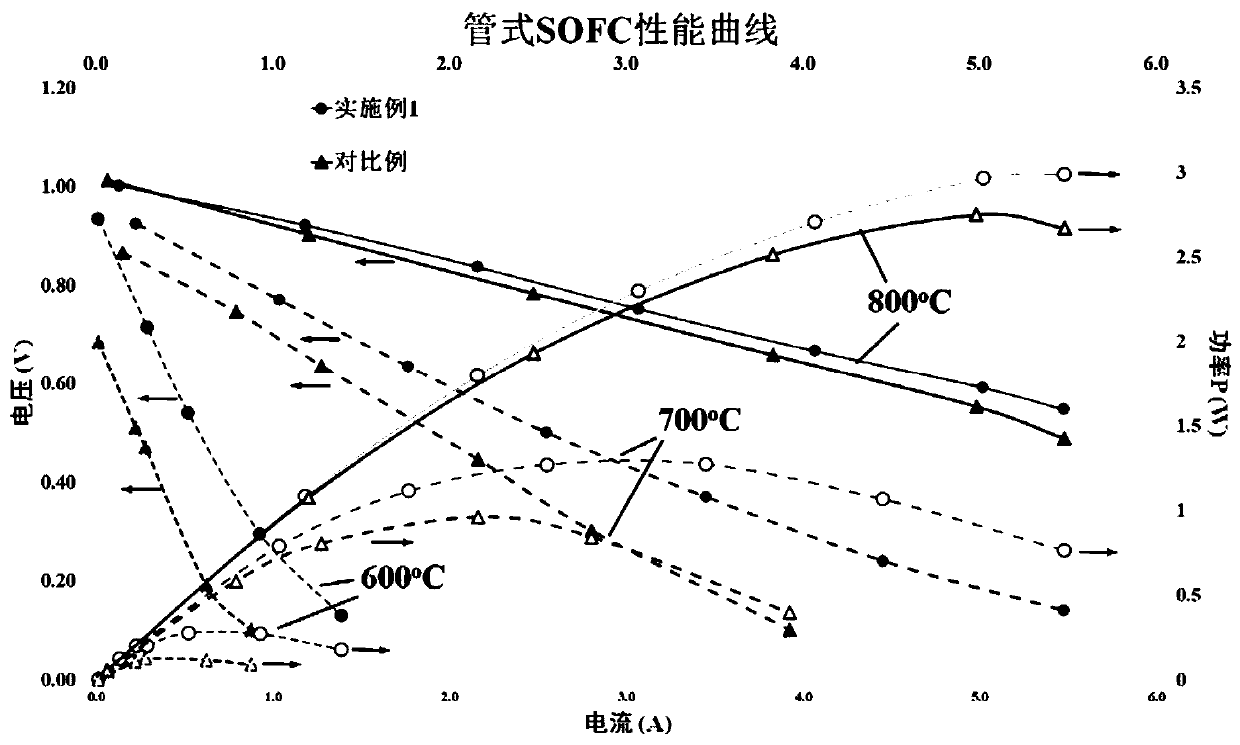

[0086] This embodiment provides the working mode of the solid fuel cell provided in Embodiment 1 and Embodiment 2.

[0087] Ammonia enters the ammonia decomposition catalyst layer 4 from the ammonia supply pipe 3, decomposes into a 3:1 hydrogen-nitrogen mixture, and enters the inner cavity 14; air enters the reaction chamber 23 from the opening at the bottom of the housing 2 through the air channel 21 When reaching a certain temperature in the reaction chamber 23, the anode layer 14 and the cathode layer 15 of the fuel cell component 1 react as follows:

[0088] Embodiment 1 uses an oxygen ion conductor as the electrolyte layer, and the specific half-reaction is:

[0089] Anode: 2NH 3 +3O 2- =N 2 +3H 2 O+6e -

[0090] Cathode: 3 / 2O 2 +6e - =3O 2- ;

[0091] Embodiment 2 uses a proton conductor as the electrolyte layer, and the specific half-reaction is:

[0092] Anode: 2NH 3 =N 2 +6H + +6e -

[0093] Cathode: 3 / 2O 2 +6e - +6H + =3H 2 O.

[0094] After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com