Perovskite solar cell based on pre-oxidation composite hole transport layer and preparation method thereof

A hole transport layer and solar cell technology, applied in the field of solar cells, can solve problems such as long oxidation time and the influence of perovskite structure, and achieve the effects of improving performance, improving hole transport capacity, and solving bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

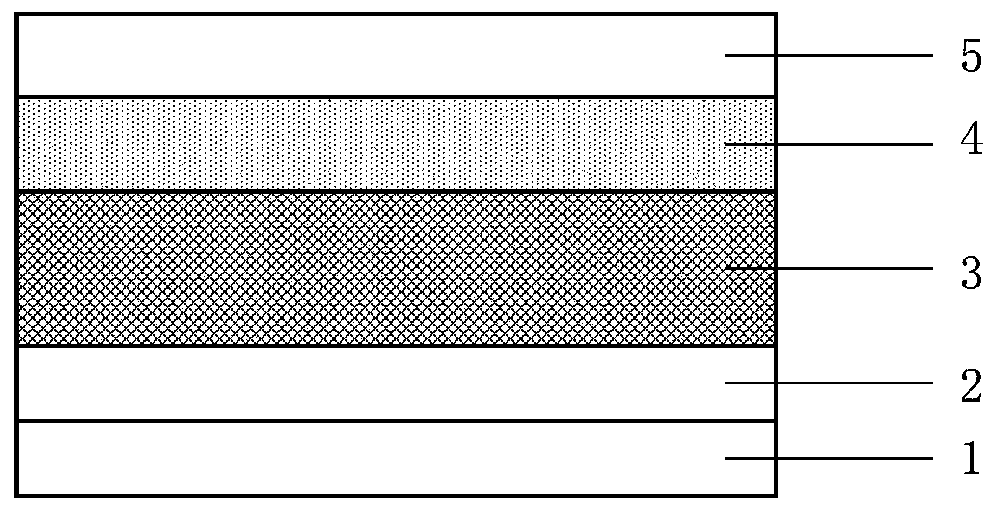

[0025] A method for preparing a perovskite solar cell based on a pre-oxidized composite hole transport layer, comprising sequentially preparing an electron transport layer, a perovskite light-absorbing layer, a composite hole transport layer, and a top electrode on a transparent conductive substrate;

[0026] Preparation of the composite hole transport layer: use oxygen with a purity of 99.9000% at 1×10 3 Oxidize 72.3mg / mL Spiro-OMeTAD solution in a vacuum sealed space for 5 minutes, mix and stir with 10mg / mL PTAA at a volume ratio of 1:1 to prepare a precursor solution, and then prepare a composite hole transport layer with a thickness of 80nm.

[0027] The concrete steps of this method are:

[0028] Step S10, using detergent, deionized water, acetone and ethanol to perform ultrasonic cleaning on the surface of the ITO transparent conductive glass substrate whose surface roughness is less than 1 nm in sequence, and blow dry with dry nitrogen after cleaning;

[0029] Step S20...

Embodiment 2

[0038] A method for preparing a perovskite solar cell based on a pre-oxidized composite hole transport layer, comprising sequentially preparing an electron transport layer, a perovskite light-absorbing layer, a composite hole transport layer, and a top electrode on a transparent conductive substrate;

[0039] Preparation of the composite hole transport layer: use oxygen with a purity of 99.0000% at 1×10 3 Oxidize 72.3 mg / mL Spiro-OMeTAD solution in Pa vacuum sealed space for 60 minutes, mix and stir with 25 mg / mL PTAA at a volume ratio of 1:1 to prepare a precursor solution, and prepare a composite hole transport layer with a thickness of 80 nm.

[0040] The preparation method of its perovskite solar cell is as follows:

[0041] The specific steps for preparing the electron transport layer, the perovskite light-absorbing layer, and the top electrode in the preparation method of this example are the same as those in Example 1, and the difference lies in the specific preparation...

Embodiment 3

[0044] A method for preparing a perovskite solar cell based on a pre-oxidized composite hole transport layer, comprising sequentially preparing an electron transport layer, a perovskite light-absorbing layer, a composite hole transport layer, and a top electrode on a transparent conductive substrate;

[0045] Preparation of the composite hole transport layer: use oxygen with a purity of 99.9000% at 1×10 3 Oxidize 72.3mg / mL Spiro-OMeTAD solution in Pa vacuum sealed space for 60 minutes, mix and stir with 35mg / mL PTAA at a volume ratio of 1:1 to prepare a mixed hole transport layer precursor, and prepare a composite hole transport layer with a preparation degree of 80nm Floor.

[0046] Most of the specific preparation steps in the preparation method of this embodiment are the same as in Example 1, only the following differences:

[0047] Weigh 35mg of PTAA, an organic hole material that does not need to be oxidized, dissolve it in 1mL of chlorobenzene, prepare a mixed solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com