Thread mounted pilot pressure reduction second-stage overflow valve

A threaded cartridge, relief valve technology, applied in the field of hydraulic control valves, can solve the problems of not meeting the requirements of short-term heavy-load working conditions of the load spectrum, weight, volume restrictions, and high power density requirements, to enhance the competitiveness of equipment, High adjustment accuracy and good adjustment linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

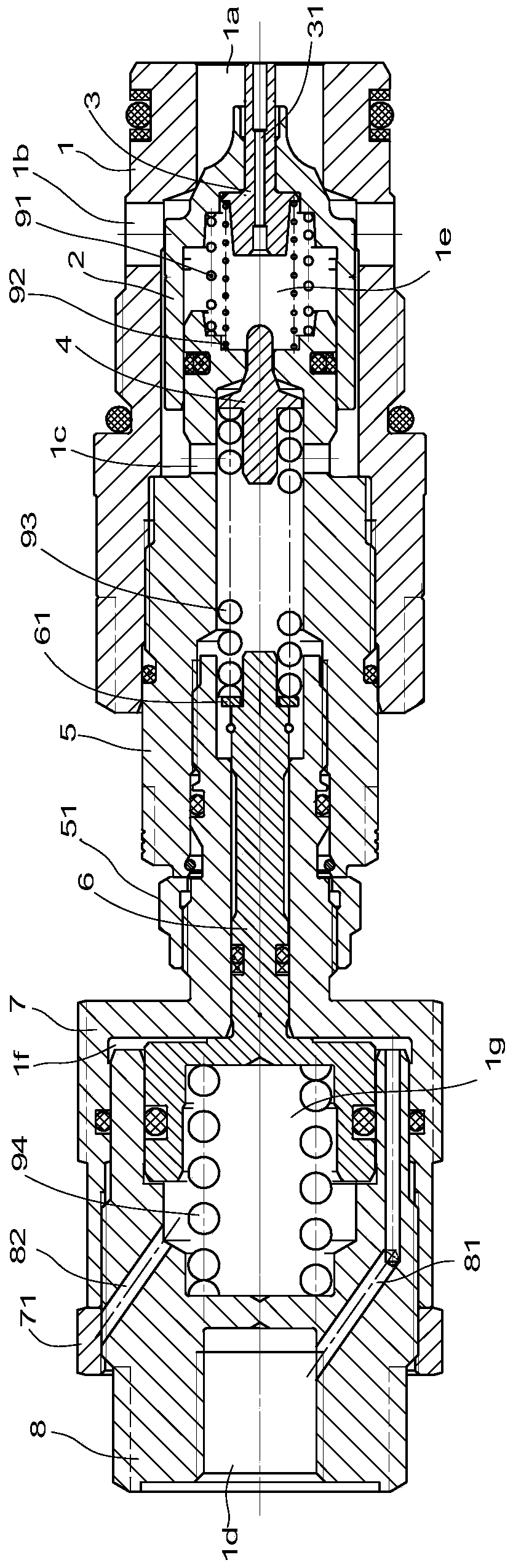

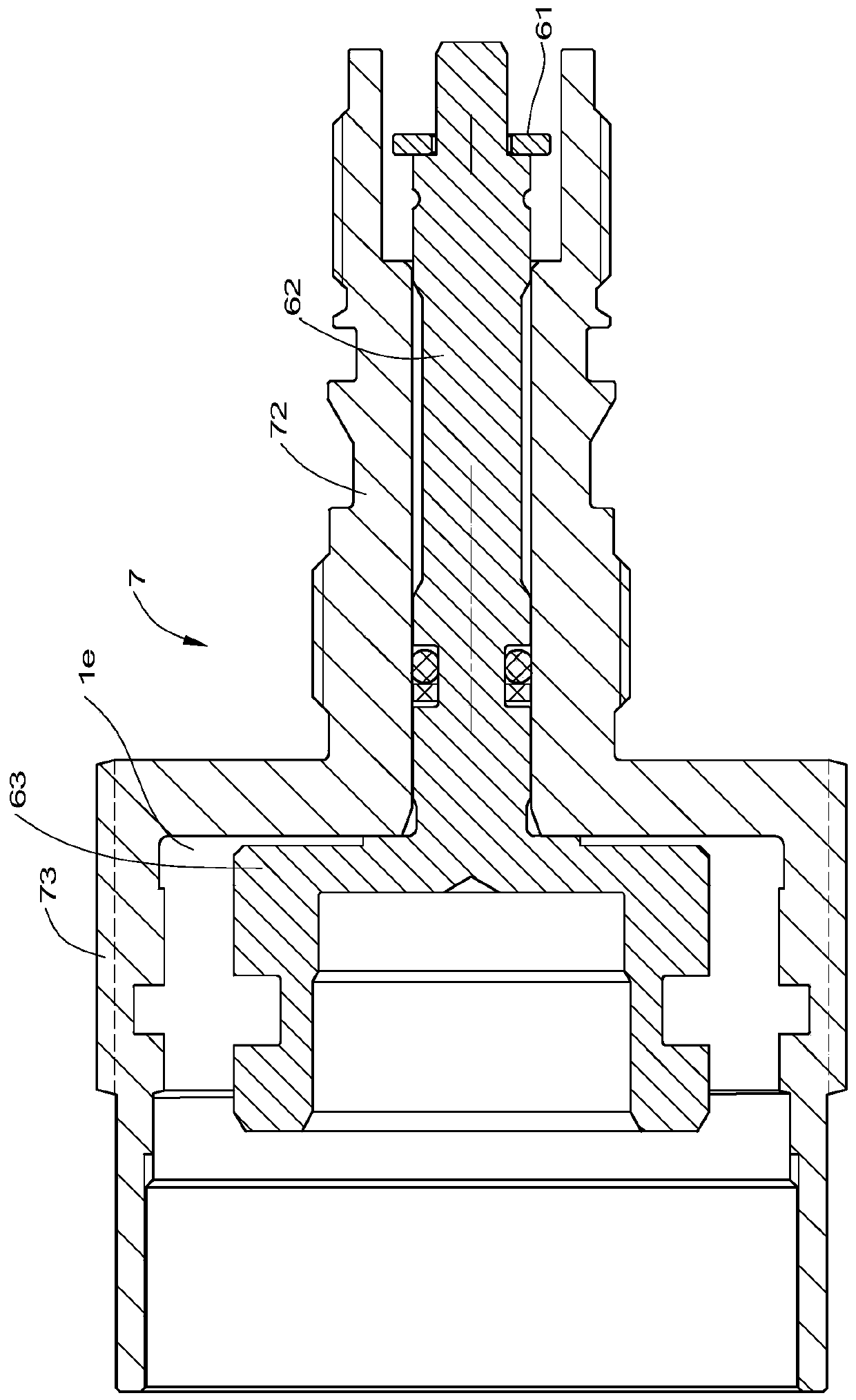

[0028] Such as figure 1 As shown, the threaded cartridge type pilot decompression secondary relief valve in this embodiment includes a main valve sleeve 1, a main valve core 2, a pilot valve seat 5, a slide valve core 3, a first spring 91, and a second spring 92 , Pilot spool 4, pressure regulating valve sleeve 7, piston 6, connecting sleeve 8, third spring 93 and fourth spring 94.

[0029] The main valve sleeve 1 is hollow in the axial direction and forms the first oil port 1a at the front end, and the second oil port 1b is formed on the side wall; the main valve core 2 is movably arranged in the main valve sleeve 1 for controlling the first oil port 1a and On-off of the second oil port 1b.

[0030] The front end of the pilot valve seat 5 is sealingly arranged at the rear end of the main valve core 2, and a first oil chamber 1e is formed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com