Photothermal sponge, and preparation method and application thereof

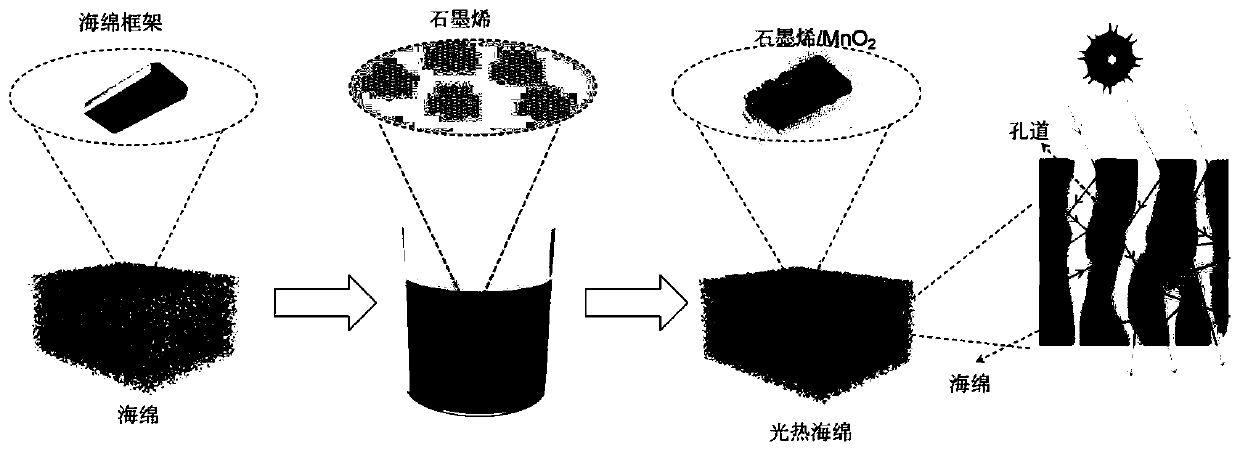

A sponge and photothermal technology, applied in the direction of separation methods, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of improving the thermal catalytic activity of metal oxides, the field of catalysis has not attracted enough attention, and is not suitable for air purification. , to achieve the effect of easy large-scale production, low production cost and rapid heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

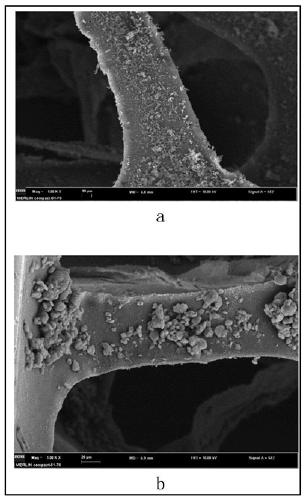

[0033] Dissolve 20mg of graphene water-based slurry in 20mL of water, sonicate in an ultrasonic instrument at 20°C for 15min, let it stand for 1min after the reaction, and take a cut 2×2×2cm 3 Soak the polyurethane sponge block in the above dispersion liquid, put it into an ultrasonic instrument at 20°C for 20 minutes, take it out and let it stand for observation. After the sponge absorbs no obvious change in color, take it out and dry it at 80°C. The SEM image of the obtained sample is attached Figure 4 a.

Embodiment 2

[0035] Dissolve 20mg of graphene dispersion in 20mL of water, sonicate in an ultrasonic instrument at 20°C for 15min, let it stand for 1min after the reaction, and take a cut 2×2×2cm 3 Soak the polyurethane sponge block in the above dispersion liquid, put it into an ultrasonic instrument at 20°C for 20 minutes, take it out and let it stand for observation. After the sponge absorbs no obvious change in color, take it out and dry it at 80°C. The SEM image of the obtained sample is attached Figure 4 b.

Embodiment 3

[0037] Dissolve 20mg of high-purity graphene in 20mL of water, sonicate in an ultrasonic instrument at 20°C for 15min, let it stand for 1min after the reaction, and take a cut 2×2×2cm 3 Soak the polyurethane sponge block in the above dispersion liquid, put it into an ultrasonic instrument at 20°C for 20 minutes, take it out and let it stand for observation. After the sponge absorbs no obvious change in color, take it out and dry it at 80°C. The SEM image of the obtained sample is attached Figure 4 c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com