Polysiloxane block polyether for preparing decoquinate emulsions and synthesizing method thereof

A polysiloxane block and decoquinate technology, which is applied in the fields of emulsion delivery, active ingredients of heterocyclic compounds, and pharmaceutical formulations, can solve the problem of large solid particles that are difficult to absorb, uneven dispersion of solid particles, and bioavailability No high problems, achieve good anti-coccidial effect, disperse without precipitation, and reduce the effect of oil-water interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

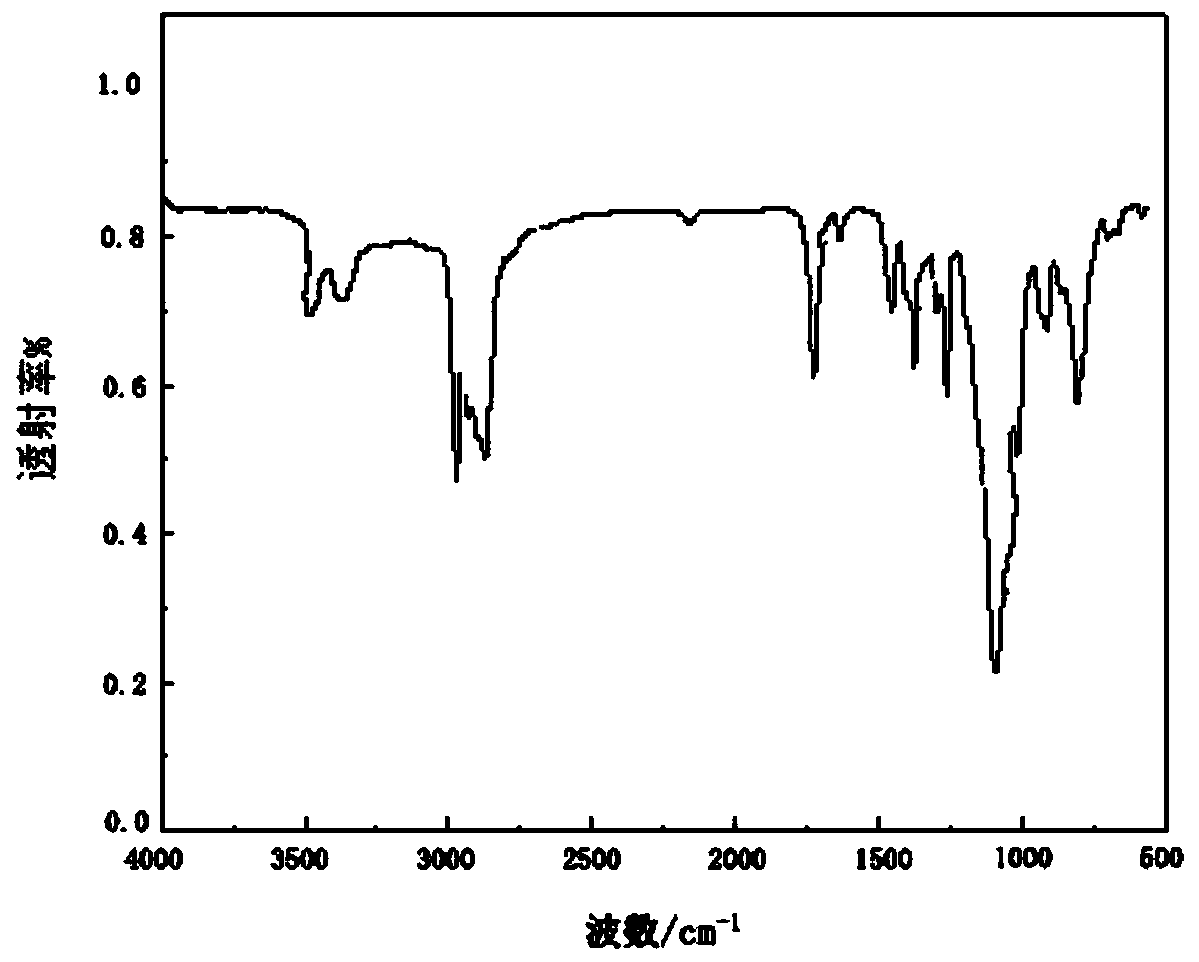

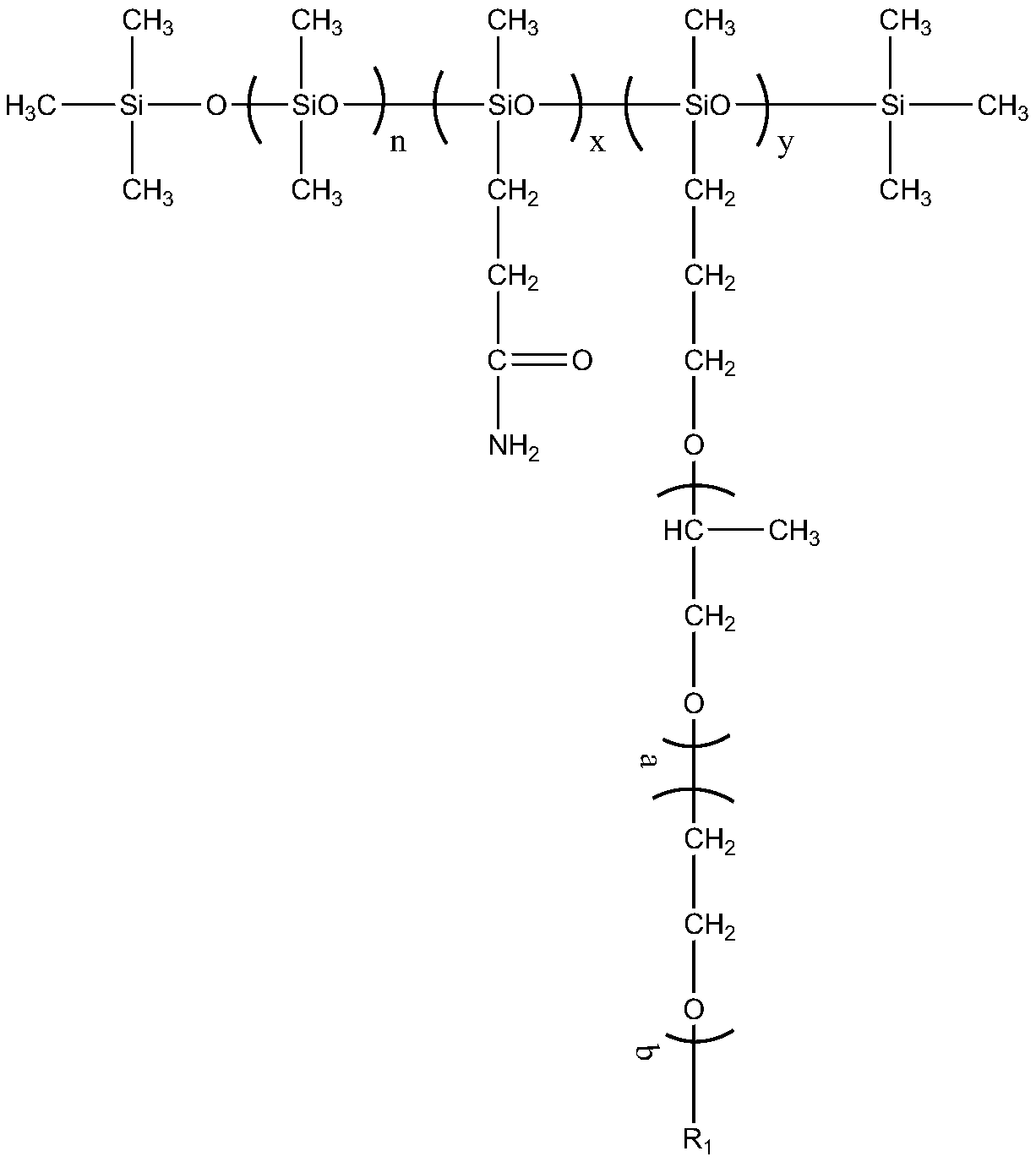

[0022] Synthetic polysiloxane block polyether emulsifier comprises the following steps:

[0023] ⑴ Hydrosilation reaction

[0024] Weigh 20 g of hydrogen-containing silicone oil (hydrogen content 0.185%), 14.00 g of isopropanol, and 60 ppm of chloroplatinic acid into a four-necked flask equipped with a dropping funnel, a spherical condenser, a thermometer, and a stirrer, and heat to 120° C.; Weigh 15.00 g of allyl polyoxyethylene polyoxypropylene ether and 3.20 g of acrylamide and mix them, then add them to the above-mentioned hydrogen-containing silicone oil system at 120°C and slowly add them dropwise for two hours to react. After the dropwise addition, continue to react at 120°C for 4 hours ;

[0025] ⑵Separation of polysiloxane block polyether emulsifier

[0026] After the hydrosilylation reaction was completed, the reaction product was poured into a separatory funnel and dissolved with 50ml chloroform, then dissolved with 0.05mol / L Na 2 CO 3 Adjust the pH of the solut...

Embodiment 2

[0032] Synthetic polysiloxane block polyether emulsifier comprises the following steps:

[0033] ⑴ Hydrosilylation reaction

[0034] Weigh 25g of hydrogen-containing silicone oil (hydrogen content 0.185%), 18.00g of isopropanol, and 60ppm of chloroplatinic acid into a four-necked flask equipped with a dropping funnel, a spherical condenser, a thermometer, and a stirrer, and heat to 130°C; Weigh 21.00 g of allyl polyoxyethylene polyoxypropylene ether and 4.20 g of acrylamide and mix them, then add them to the hydrogen-containing silicone oil system at 130°C and slowly add them dropwise for two hours to react. After the dropwise addition, continue to react at 120°C for 5 hours ;

[0035] ⑵Separation of polysiloxane block polyether emulsifier

[0036] After the hydrosilylation reaction was completed, the reaction product was poured into a separatory funnel and dissolved with 50ml of chloroform, then dissolved with 0.09mol / L Na 2 CO 3 Adjust the pH of the solution to neutral, ...

Embodiment 3

[0038] The decoquinate emulsion made by the polysiloxane block polyether emulsifier of the present invention has been compared with two kinds of anticoccidial drugs of decoquinate premix and decoquinate solution, to verify The emulsifier of the present invention has an anti-coccidial effect of the decoquinate emulsion.

[0039]The spare chickens for the test were weighed one by one. According to the results of biostatistical analysis, the individuals with significant weight differences were eliminated so that the weight range was between 110-125g. Each chicken was marked with a foot number and randomly divided into 6 groups with 15 chickens in each group. , so that the total body weight of each group of chickens is approximately equal. The Ⅰ group is the non-infected non-medication group (white control group), the Ⅱ group is the infection non-medication group (red control group), the Ⅲ, Ⅳ, Ⅴ, and Ⅵ groups are the decoquinate drug groups, and the same dosage is administered res...

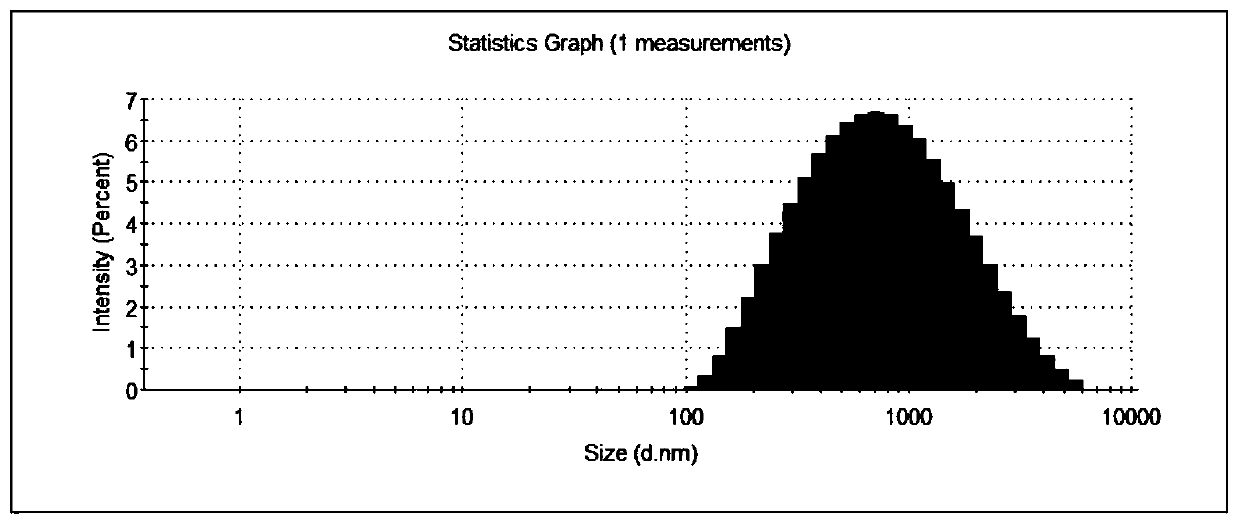

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com