Method for preparing 2,5-furandicarboxylic acid by one-step cleaning

A furandicarboxylic acid, clean technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve the problem of high price, high production cost of 2,5-furandialdehyde, HMF separation difficulties and other problems, to achieve the effect of easy transportation, reduce production costs and the difficulty of separation and purification, and improve catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

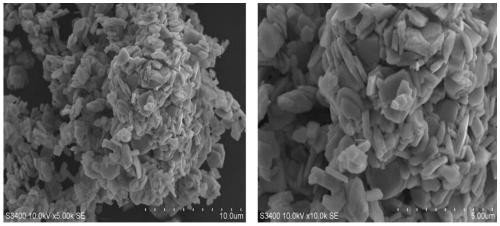

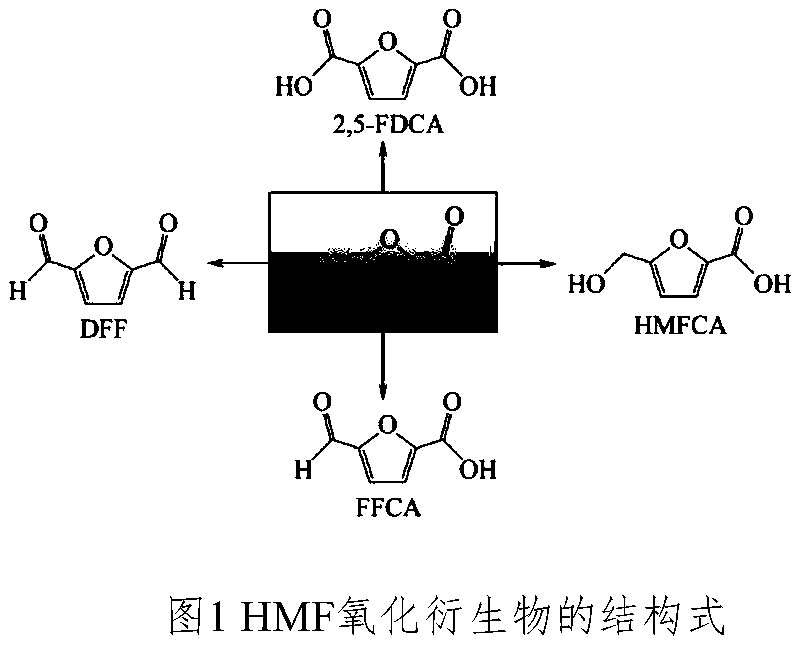

Method used

Image

Examples

Embodiment 1

[0047] One-step cleaning method for preparing 2,5-furandicarboxylic acid, comprising the following steps:

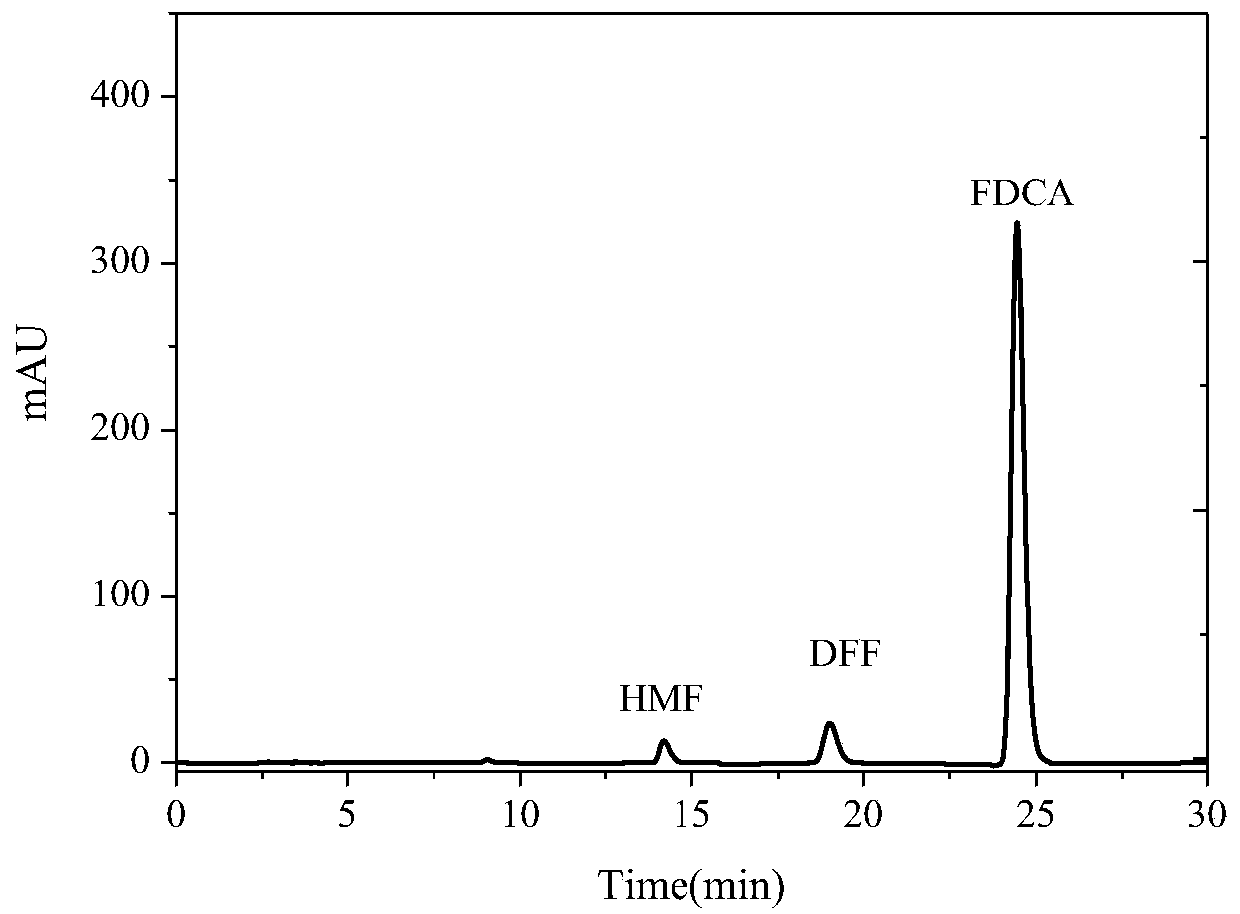

[0048] Mix 8g of fructose, 0.5g of sodium carbonate-zinc glutarate with a mass ratio of 2:1, 0.45g of ruthenium lanthanum niobate catalyst, and 100g of hydrogen peroxide and 1,3-dimethyl- The mixed solvent composed of 2-imidazolinone solution and dimethyl carbonate is poured into the high-pressure reaction kettle, quickly sealed and stirred at a speed of 300r / min, and the volume ratio of 1:2.5 is introduced into the CO 2 / O 2 Mix the gas until the pressure in the autoclave is 8MPa, then heat it to 195°C, stop the reaction after 25 minutes of reaction, take 1mL of the reaction solution from the sampling tube and analyze the product by high performance liquid chromatography, and the following results are obtained: the fructose conversion rate is 98.78%, and the yield of 2,5-furandicarboxylic acid was 50.53%.

Embodiment 2

[0050] One-step cleaning method for preparing 2,5-furandicarboxylic acid, comprising the following steps:

[0051] Mix 15g of sucrose, 0.5g of sodium carbonate-zinc glutarate with a mass ratio of 4:1, 0.40g of ruthenium lanthanum niobate catalyst, and 100g of hydrogen peroxide and 1,3-dimethyl- The mixed solvent composed of 2-imidazolinone solution and dimethyl carbonate is poured into the high-pressure reaction kettle, and it is quickly sealed and stirred at a speed of 300r / min, and CO with a volume ratio of 1:3 is introduced. 2 / O 2 Mix the gas until the pressure in the autoclave is 6MPa, then heat it to 191°C, stop the reaction after 45 minutes of reaction, take 1mL of the reaction solution from the sampling tube and analyze the product with high performance liquid chromatography, and the following results are obtained: the conversion rate of sucrose is 94.38%, 2,5-furandicarboxylic acid yield was 20.21%.

Embodiment 3

[0053] One-step cleaning method for preparing 2,5-furandicarboxylic acid, comprising the following steps:

[0054] Mix 9g of glucose, 0.5g of sodium carbonate-zinc glutarate with a mass ratio of 1:1, 0.35g of ruthenium-based lanthanum niobate catalyst, and 100g of hydrogen peroxide and 1,3-dimethyl- The mixed solvent composed of 2-imidazolinone solution and dimethyl carbonate is poured into the high-pressure reaction kettle, and it is quickly sealed and stirred evenly at a speed of 300r / min, and CO with a volume ratio of 1:1 is introduced. 2 / O 2 Mix the gas until the pressure in the autoclave is 7.2 MPa, then heat it to 190°C, stop the reaction after 35 minutes of reaction, take 1mL of the reaction solution from the sampling tube and analyze the product by high performance liquid chromatography, and the following results are obtained: Glucose The conversion rate was 88.83%, and the yield of 2,5-furandicarboxylic acid was 30.24%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com