Preparation process for reclaimed concrete aggregates and reclaimed concrete employing reclaimed concrete aggregates

A technology of recycled concrete and preparation technology, which is applied in the field of concrete construction, can solve the problems of recycled concrete application with low mechanical properties, low utilization rate of recycled concrete, and low strength of recycled concrete, so as to improve mechanical strength and weather resistance, improve mechanical Strength and durability, effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] The invention discloses a preparation process of recycled concrete aggregate, which comprises the following process steps:

[0095] S1: Pretreatment: Hammering waste concrete blocks, making the diameter of the hammered concrete blocks less than 50mm, and stripping the steel bars;

[0096] S2: Enhanced treatment:

[0097] 1) Wet treatment: Put the concrete block obtained in S1 into the clear water tank, use ultrasonic cleaning for 30 minutes, and continuously stir, after cleaning, let it stand for 30 minutes, remove the suspended matter suspended above the clear water tank, and remove Remove the pieces and dry them in the air until there is no obvious water stain on the surface;

[0098] 2) Acid treatment: import the wet-treated concrete block into an acidic pool and soak for 20 minutes, then import it into an alkaline pool and soak for 15 minutes, and then import it into a cleaning pool for washing. After washing, remove the concrete block Let it dry until there is no...

Embodiment 1

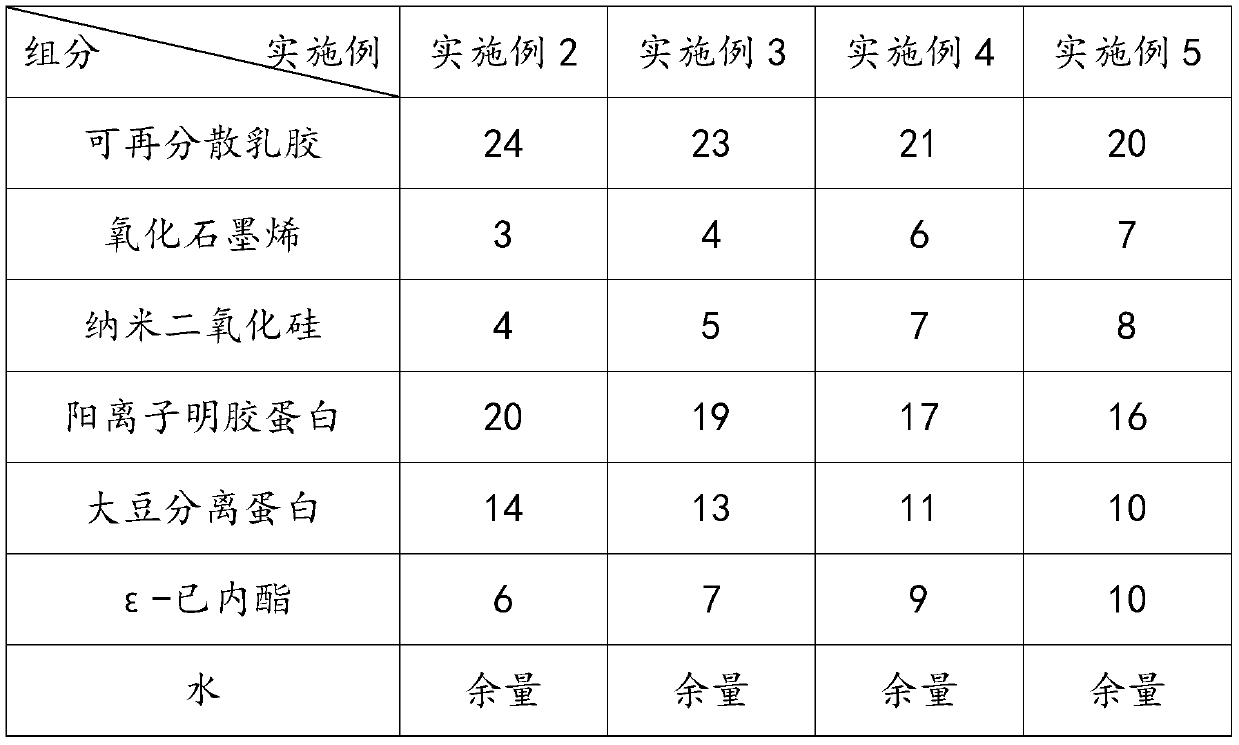

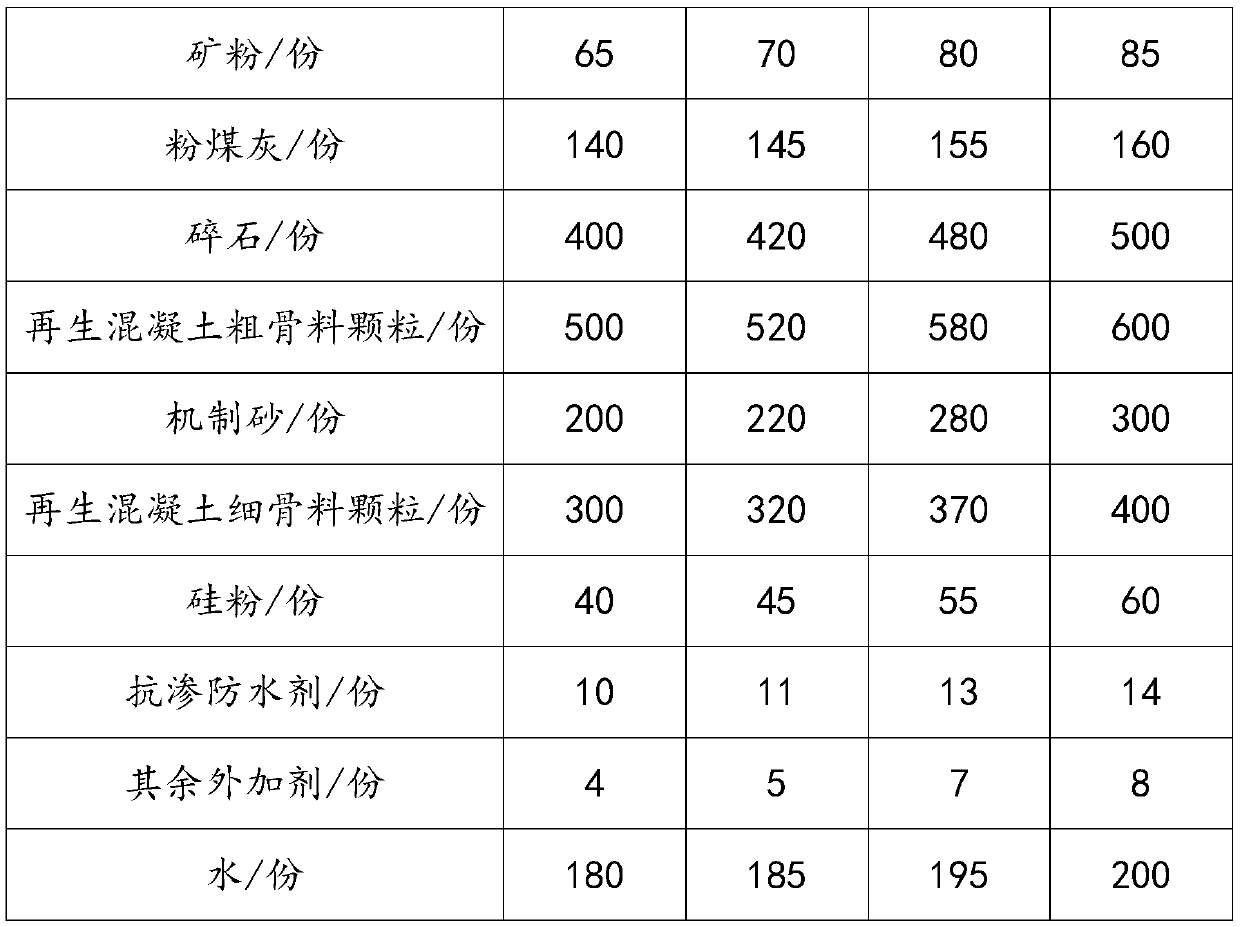

[0122] The difference between embodiments 10-13 and embodiment 1 is that the anti-seepage and waterproofing agent comprises the following weight percentages:

[0123]

[0124]

[0125] The difference between embodiments 14-17 and embodiment 1 is that the fibrous filler comprises the following weight percentages:

[0126]

[0127] The difference between embodiment 14-17 and embodiment 1 is that all the other admixtures include the following raw materials in weight percentage:

[0128]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com