Gas hole-sealing material used in coal mine well and preparation method thereof

A sealing material and gas technology, applied in the field of gas sealing material and its preparation, to achieve the effects of long setting time, improving interface performance, and reducing easy shrinkage and dry cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

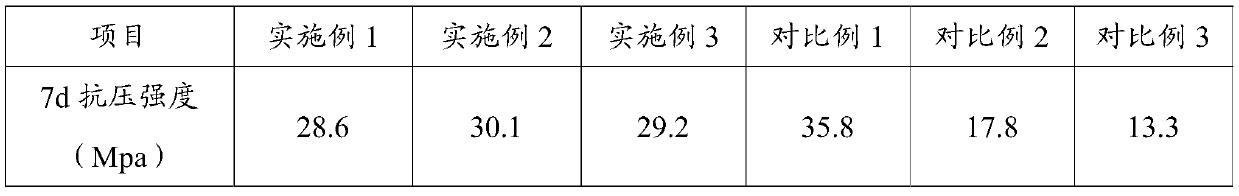

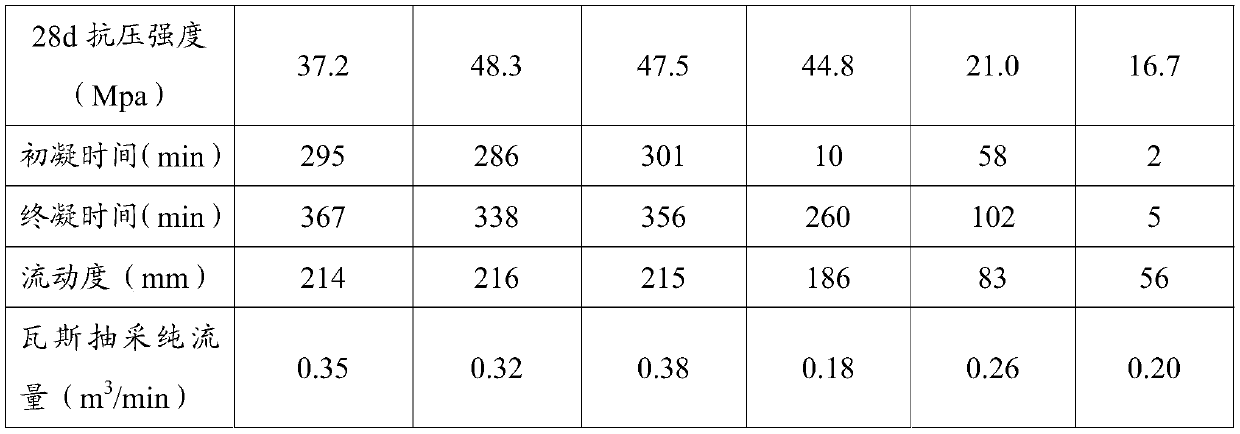

Examples

Embodiment 1

[0032] A gas sealing material for underground coal mines, made of the following components by weight: Portland cement 300g, humic acid modified polyurethane 80g, basalt fiber 40g, carboxymethyl cellulose 1g, RSD-8 type High-efficiency water reducer 3g, silane coupling agent KH560 3g.

[0033] The specific preparation method is as follows:

[0034] Step 1, prepare humic acid modified polyurethane

[0035] 3g humic acid is dissolved with 50g of N,N'-dimethylformamide to obtain humic acid solution;

[0036] Mix 50g of isophorone diisocyanate and 53g of humic acid solution, heat to 60°C for 3 hours, then add 200g of polyether polyol NJ-210 and 10g of 2,2-dimethylol propionic acid, mix Evenly, add 3g of dibutyltin dilaurate dropwise at a rate of 1 drop / s, react at 80°C for 3 hours, and then the temperature drops to 40°C, then add triethylamine to neutralize to a pH of 7.2 to obtain a prepolymer;

[0037] adding an aqueous solution of ethylenediamine with a mass concentration of ...

Embodiment 2

[0044] A gas sealing material for underground coal mines, made of the following components in parts by weight: Portland cement 200g, humic acid modified polyurethane 100g, basalt fiber 30g, carboxymethyl cellulose 1.5g, RSD -8 type superplasticizer 1g, silane coupling agent KH560 5g.

[0045] The specific preparation method is the same as in Example 1, except that the formula in Example 1 is changed to that of Example 2.

Embodiment 3

[0047] A gas sealing material for underground coal mines, made of the following components in parts by weight: Portland cement 400g, humic acid modified polyurethane 50g, basalt fiber 50g, carboxymethyl cellulose 2g, RSD- Type 8 superplasticizer 5g, silane coupling agent KH560 1g.

[0048] The specific preparation method is the same as in Example 1, except that the formula in Example 1 is changed to that of Example 3.

[0049]In order to further illustrate the effects of the present invention, the present invention also provides comparative examples, specifically as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com