Green-fluorescence carbon quantum dot, and preparation method and application thereof

A technology of green fluorescence and carbon quantum dots, applied in fluorescence/phosphorescence, chemical instruments and methods, nano-carbon, etc., can solve the problems of high requirements for instruments and cumbersome steps, and achieve uniform particle size distribution, simple preparation process, and stable properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing green fluorescent carbon quantum dots. Weigh 2mmol of o-phenylenediamine, 1mmol of thiourea and 20mL of ethanol in a hydrothermal kettle, slowly raise the temperature to 180°C, and keep the temperature for 8 hours. Cool naturally after the reaction is over, then pour the cooled reaction solution in the hydrothermal kettle into a round bottom flask, install the round bottom flask on a rotary evaporator, adjust the temperature to 45°C for vacuum distillation, and wait for the round bottom flask to The reaction solution evaporated completely, leaving a black residue on the bottle wall. Pour 15mL of distilled water into the round bottom flask three times, and the residue on the bottle wall was dissolved Pour the solution into a centrifuge tube in distilled water, put it into a high-speed centrifuge, set the speed at 9000 rpm, and centrifuge for 10 minutes. After centrifugation, pour the supernatant into a small test tube, and then filter through a 0.2...

Embodiment 2

[0036] A method for preparing green fluorescent carbon quantum dots. Weigh 0.5 mmol of o-phenylenediamine, 0.5 mmol of thiourea and 5 mL of ethanol in a hydrothermal kettle, slowly raise the temperature to 120° C., and keep the temperature for 12 hours. Cool naturally after the reaction is over, then pour the cooled reaction solution in the hydrothermal kettle into a round bottom flask, install the round bottom flask on a rotary evaporator, adjust the temperature to 30°C for vacuum distillation, and wait for the round bottom flask to The reaction liquid in the bottle evaporates completely, leaving a black residue on the bottle wall. Pour the distilled water into the round bottom flask three times. , pour the solution into a centrifuge tube, put it into a high-speed centrifuge, set the speed at 4000 rpm, and centrifuge for 12 minutes. After centrifugation, pour the supernatant into a small test tube, and then filter it with a 0.1 micron filter membrane to obtain a filtrate show...

Embodiment 3

[0038] A method for preparing green fluorescent carbon quantum dots. Weigh 5 mmol of o-phenylenediamine, 5 mmol of thiourea and 50 mL of ethanol in a hydrothermal kettle, slowly raise the temperature to 200° C., and keep the temperature for 4 hours. Cool naturally after the reaction is over, then pour the cooled reaction solution in the hydrothermal kettle into a round bottom flask, install the round bottom flask on a rotary evaporator, adjust the temperature to 80°C for vacuum distillation, and wait for the round bottom flask to The reaction liquid in the bottle evaporates completely, leaving a black residue on the bottle wall. Pour the distilled water into the round bottom flask three times. , pour the solution into a centrifuge tube, put it into a high-speed centrifuge, set the speed at 10,000 rpm, and centrifuge for 4 minutes. After centrifugation, pour the supernatant into a small test tube, and then filter through a 0.8-micron filter membrane to obtain a filtrate showing...

PUM

| Property | Measurement | Unit |

|---|---|---|

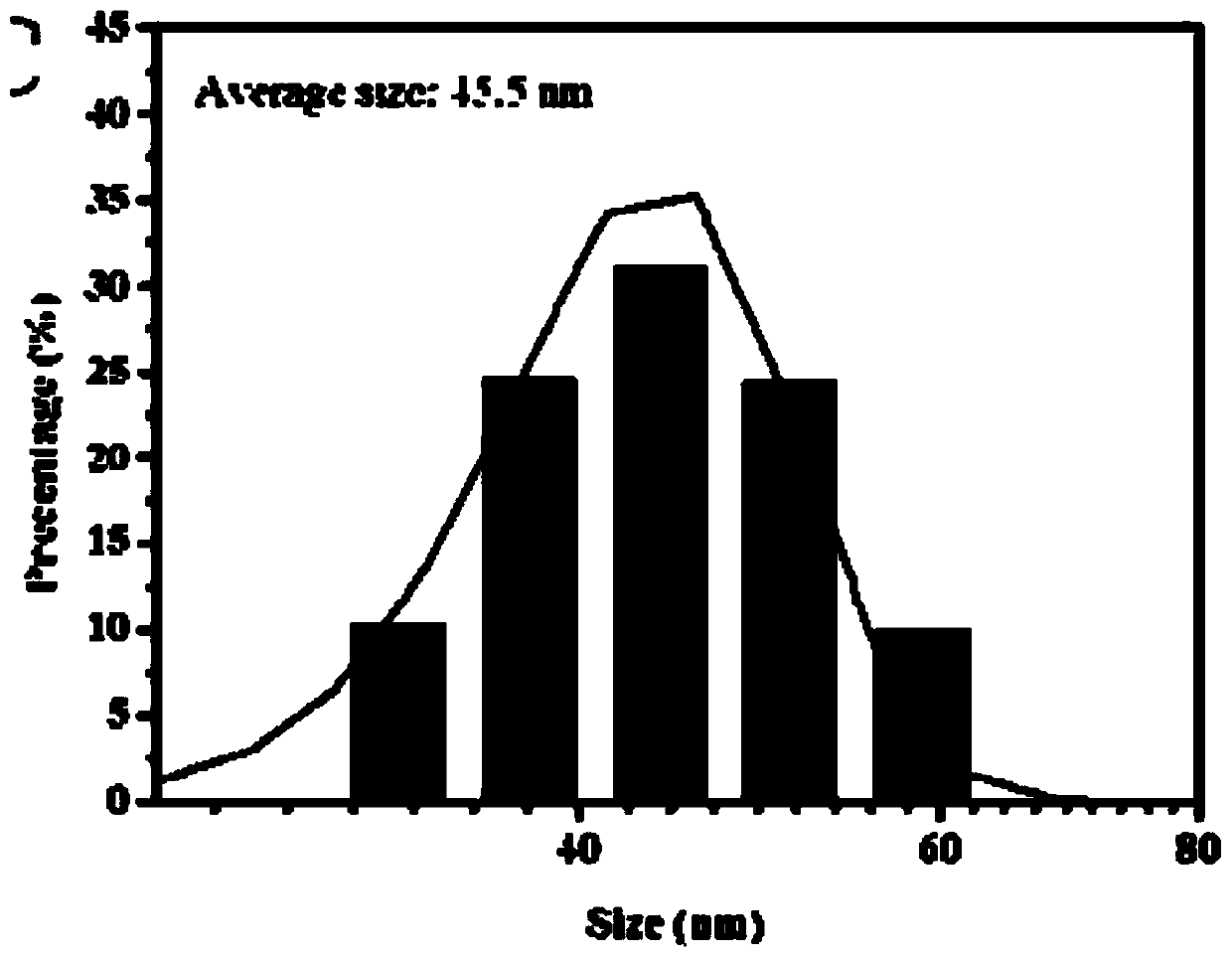

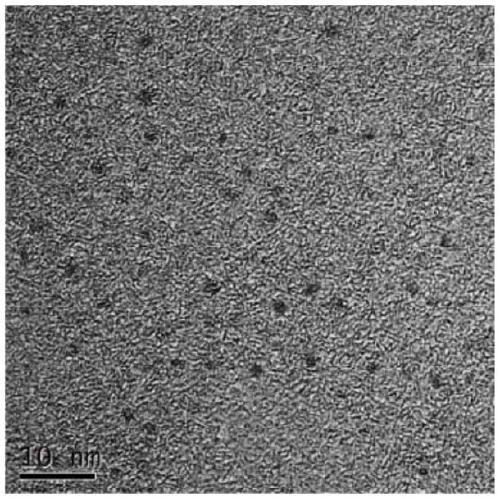

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com