Folding type wide film extrusion die design method

A design method and folding technology, applied in the field of folding wide-width film extrusion die design, can solve the problems of high manufacturing cost, high casting and design difficulty, and difficulty in adjusting extrusion rate deviation, so as to reduce scale and reduce casting. and design difficulty, avoid the effect of collaborative control and process adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

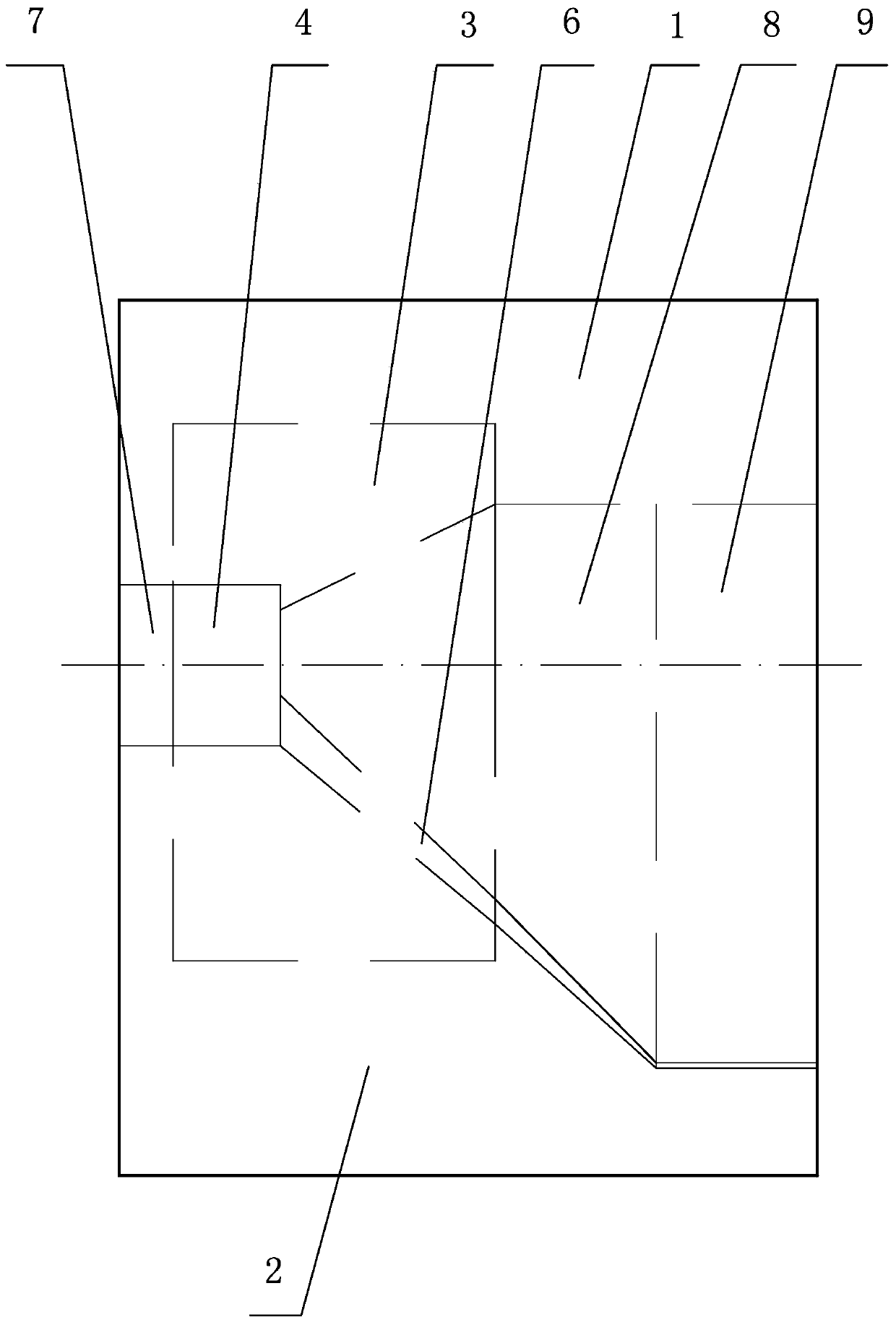

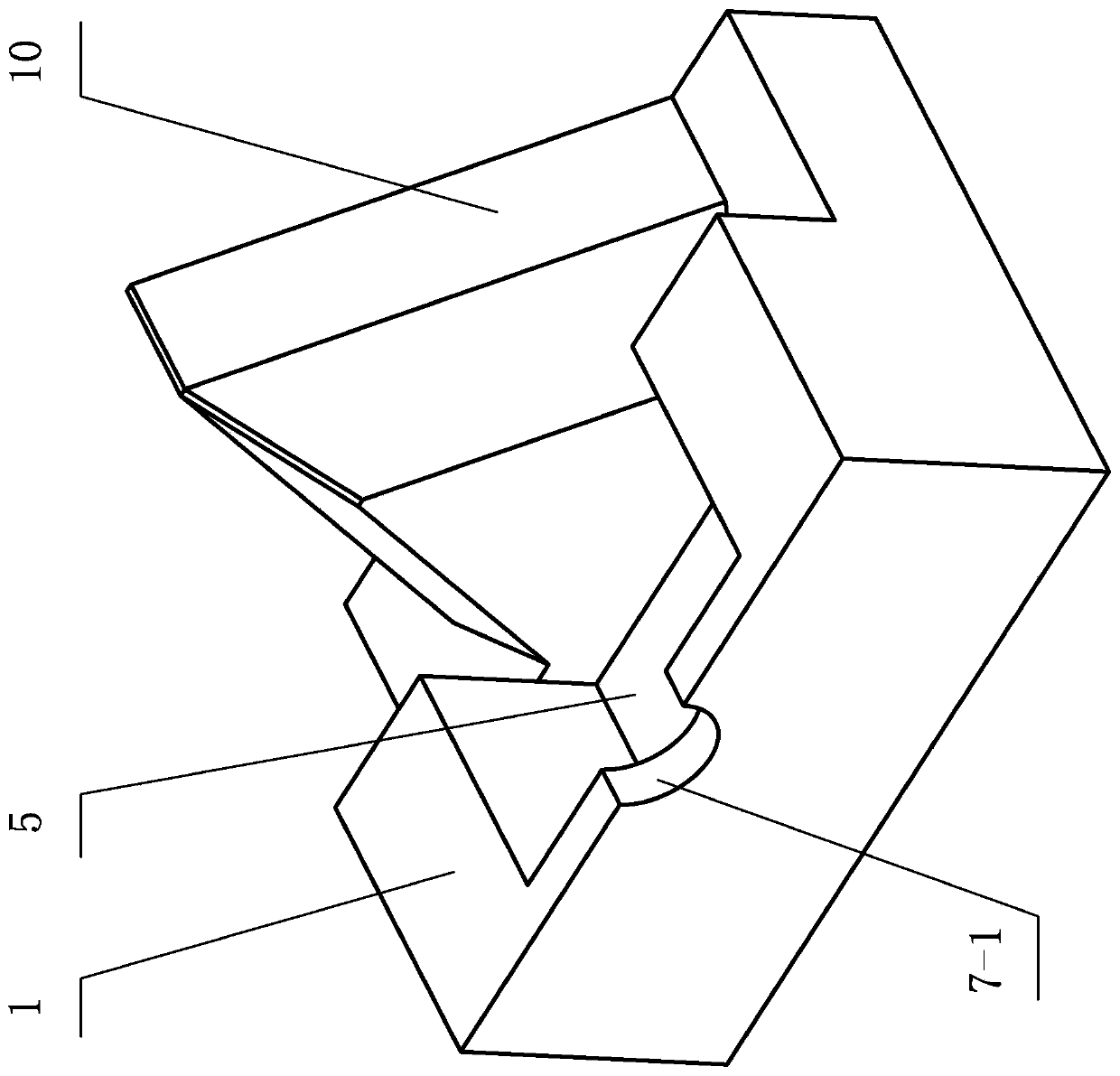

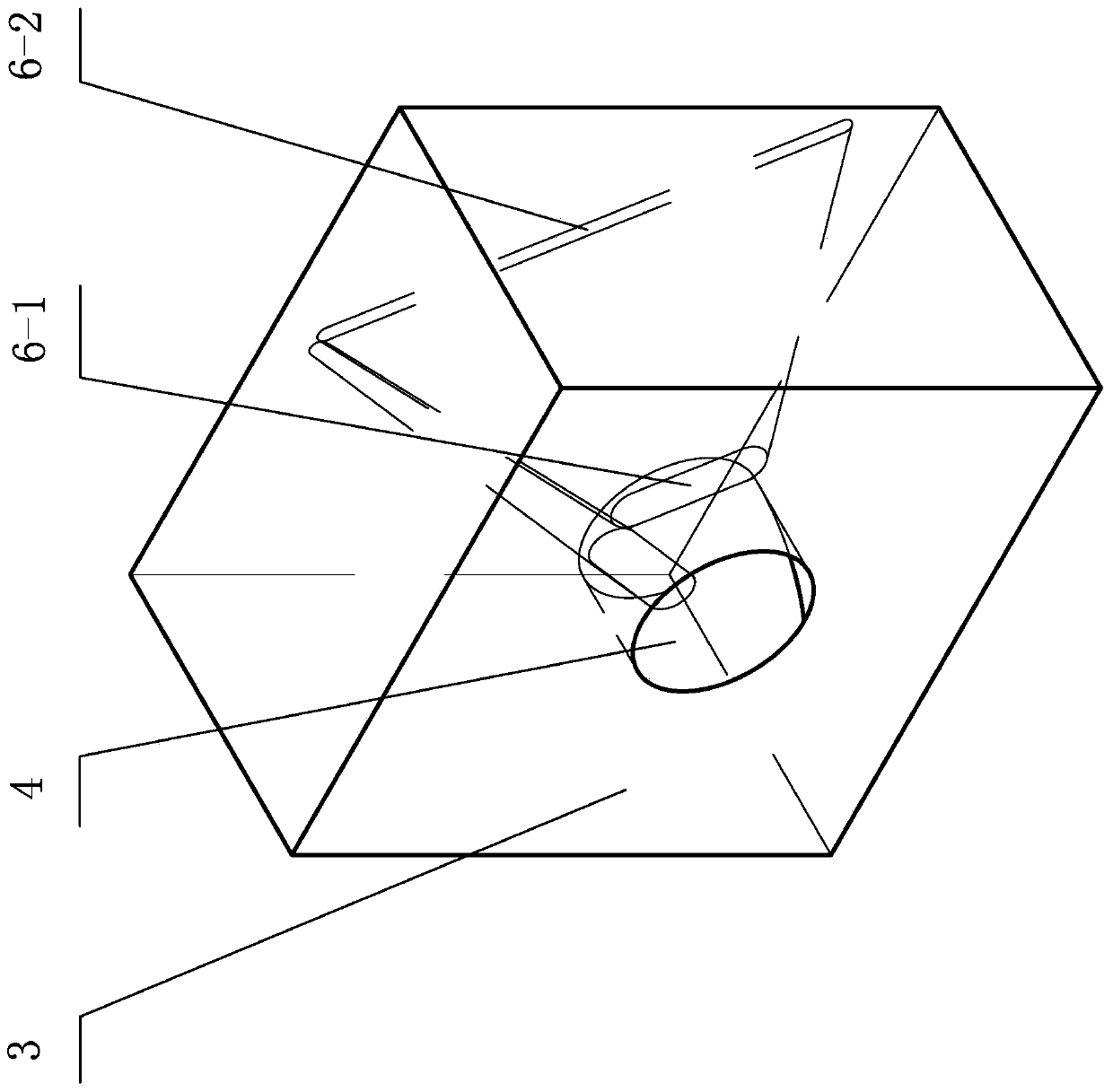

[0020] The design method of the folded wide-width film extrusion die of the present invention includes the design of the extrusion die composed of the upper die 1, the lower die 2 and the splitter 3, the splitter 3 is a square body, and the front part of the splitter 3 A circular blind hole cavity 4 is opened in the center, and the front end of the circular blind hole cavity 4 leads out of the front end surface of the diverter 3, and a V-shaped fishtail-shaped flow channel cavity 6 is opened in the rear part of the diverter 3 (V-shaped from front to back). gradually increases and the thickness gradually becomes thinner), the front end of the V-shaped fishtail-shaped runner chamber 6 leads out of the bottom of the circular blind hole chamber 4, and the rear end of the V-shaped fishtail-shaped runner chamber 6 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com