Dissimilar metal welding method of low-carbon steel and cast iron

A technology of dissimilar metals and welding methods, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as increased cracking tendency, large heat input, fast cooling speed, etc., to improve crack resistance and increase bearing capacity , heat effect is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The laser lap welding method of dissimilar metals of low carbon steel and cast iron comprises the following steps:

[0032] S1. Prepare base metal: low-carbon steel 1 has a carbon content of 0.07wt%, and the thickness of the low-carbon steel is 0.5mm; cast iron 2 has a carbon content of 2wt%, and the thickness of cast iron 2 is 1mm;

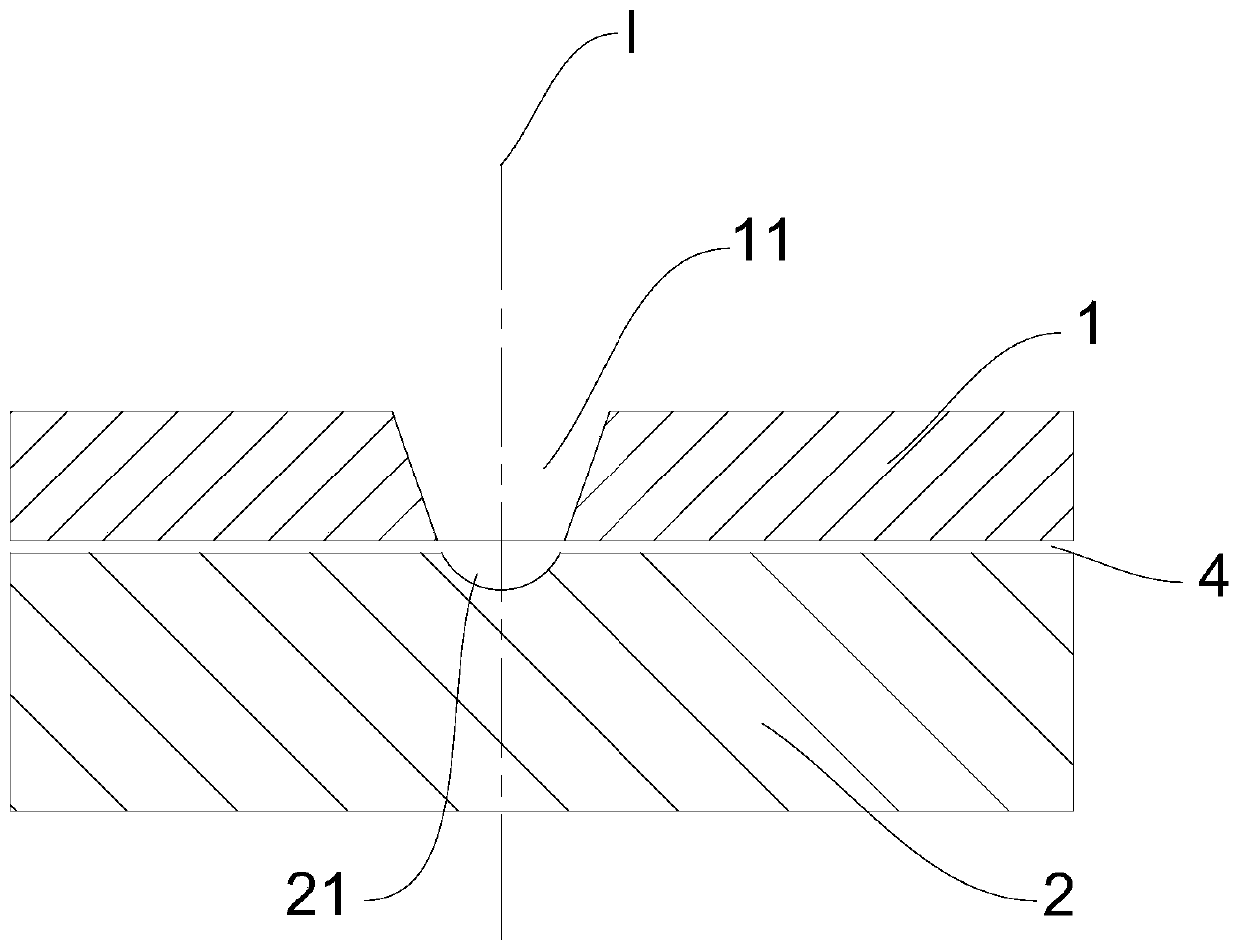

[0033] S2. Base metal surface cleaning and assembly: clean the base metal and remove oxides on the surface, that is, clean up the oil stains and rust in the area to be welded, and assemble the surface-cleaned low-carbon steel 1 to be welded with the cast iron 2 from top to bottom. The tooling fixture is fixed to form the parts to be welded, and the assembly gap 4 of the lap joint between the low carbon steel 1 and the cast iron 2 is 0mm;

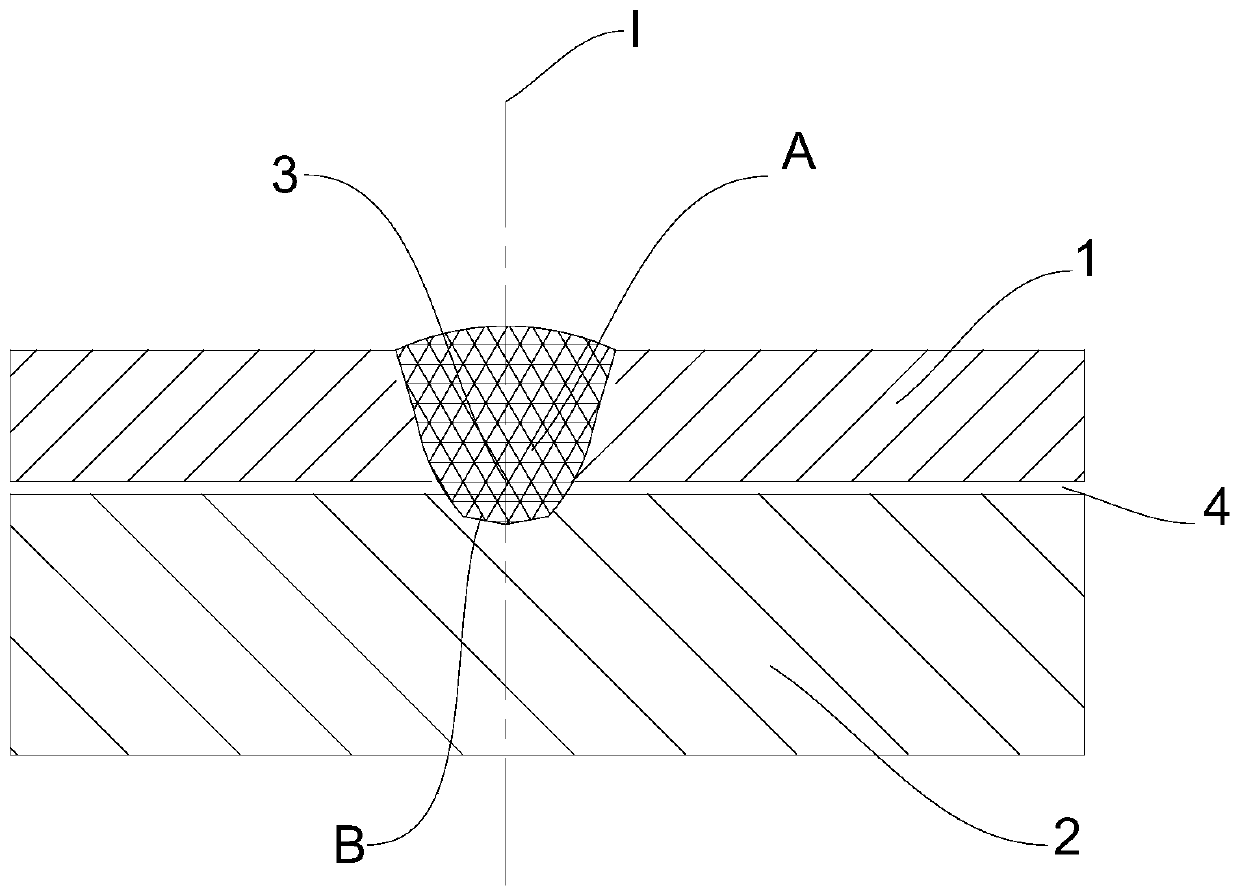

[0034] S3. Welding process: using galvanometer laser welding head, swinging and self-fluxing welding during welding, laser incident from the side of low carbon steel, laser welding will completely penetr...

Embodiment 2

[0038] The laser lap welding method of dissimilar metals of low carbon steel and cast iron comprises the following steps:

[0039] S1. Prepare base metal: low-carbon steel 1 has a carbon content of 0.3wt%, and the thickness of the low-carbon steel is 4mm; cast iron 2 has a carbon content of 2.5wt%, and the thickness of cast iron 2 is 10mm;

[0040] S2. Base metal surface cleaning and assembly: clean the base metal and remove oxides on the surface, that is, clean up the oil stains and rust in the area to be welded, and assemble the surface-cleaned low-carbon steel 1 to be welded with the cast iron 2 from top to bottom. The tooling fixture is fixed to form the parts to be welded, and the assembly gap 4 of the lap joint between the low carbon steel 1 and the cast iron 2 is 0.2mm;

[0041] S3. Welding process: using galvanometer laser welding head, swinging and self-fluxing welding during welding, laser incident from the side of low carbon steel, laser welding will completely pene...

Embodiment 3

[0045] The laser lap welding method of dissimilar metals of low carbon steel and cast iron comprises the following steps:

[0046] S1. Prepare base metal: low-carbon steel 1 has a carbon content of 0.6wt%, and the thickness of the low-carbon steel is 8mm; cast iron 2 has a carbon content of 4wt%, and the thickness of cast iron 2 is 30mm;

[0047] S2. Base metal surface cleaning and assembly: clean the base metal and remove oxides on the surface, that is, clean up the oil stains and rust in the area to be welded, and assemble the surface-cleaned low-carbon steel 1 to be welded with the cast iron 2 from top to bottom. The tooling fixture is fixed to form the parts to be welded, and the assembly gap 4 of the lap joint between the low carbon steel 1 and the cast iron 2 is 0.5mm;

[0048] S3. Welding process: using galvanometer laser welding head, swinging and self-fluxing welding during welding, laser incident from the side of low carbon steel, laser welding will completely penetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com