Groove machining blade with double cutting units and cutting tool

A groove machining and double cutting technology, applied in the field of metal cutting, can solve the problems of low cutting efficiency, large cutting depth, poor positioning rigidity, etc., and achieve the effect of improving cutting efficiency and life, improving surface quality and improving cutting rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

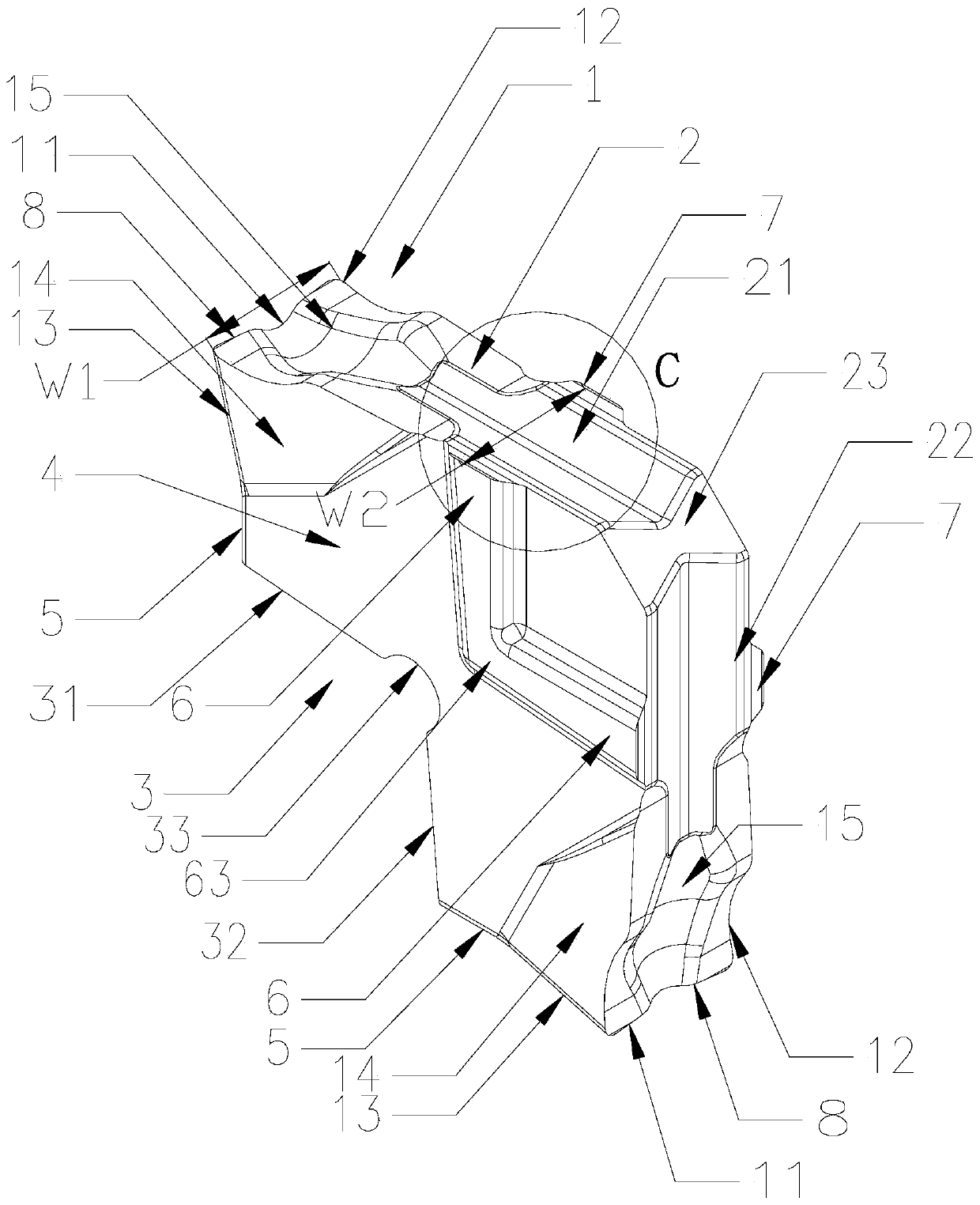

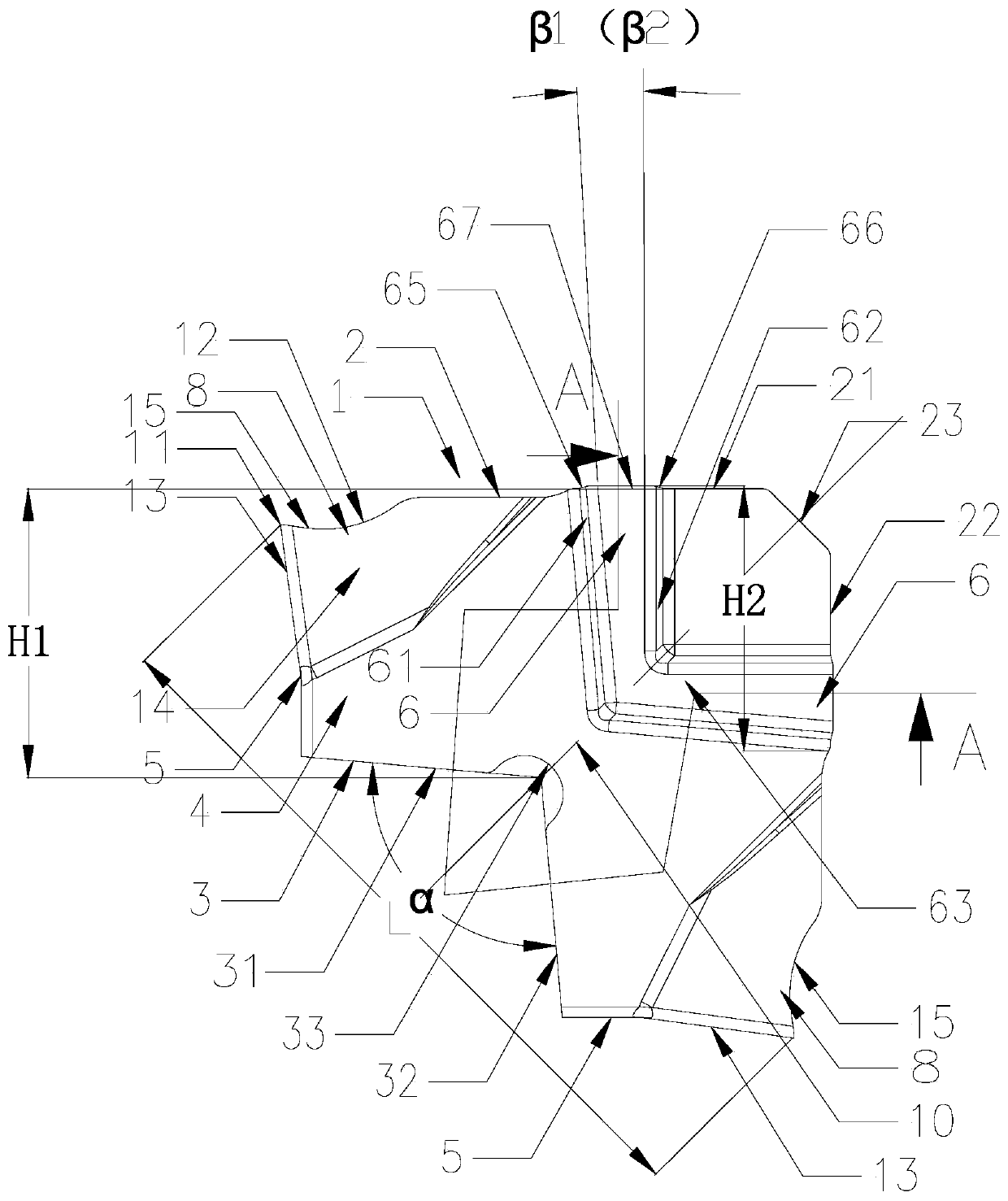

[0041] Such as Figure 1 to Figure 4 As shown, in the grooving insert with double cutting units in this embodiment, the insert 1 includes an upper surface 2, a lower surface 3, two side surfaces 4 and two end surfaces 5 connecting the upper and lower surfaces, the upper surface 2, the lower surface 3 Symmetrical about the mid-side plane 9 at the center of the two side surfaces 4, the upper surface 2 includes an upper horizontal positioning surface 21, an upper vertical positioning surface 22 and an upper transition surface 23 between the upper horizontal positioning surface 21 and the upper vertical positioning surface 22, and the lower surface 3. It is composed of the lower horizontal positioning surface 31, the lower vertical positioning surface 32 and the lower transition surface 33 between the lower horizontal positioning surface 31 and the lower vertical positioning surface 32. Between the upper horizontal positioning surface 21 and an end surface 5, the upper vertical pos...

Embodiment 2

[0054] Such as Figures 5 to 8 As shown, the groove machining insert with double cutting units of this embodiment is basically the same as that of Embodiment 1, the only difference being:

[0055] In this embodiment, one first cutting unit 6 and one second cutting unit 7 are respectively provided, the first cutting unit 6 is symmetrical about the mid-end plane 10 , and the second cutting unit 7 is symmetrical about the mid-end plane 10 .

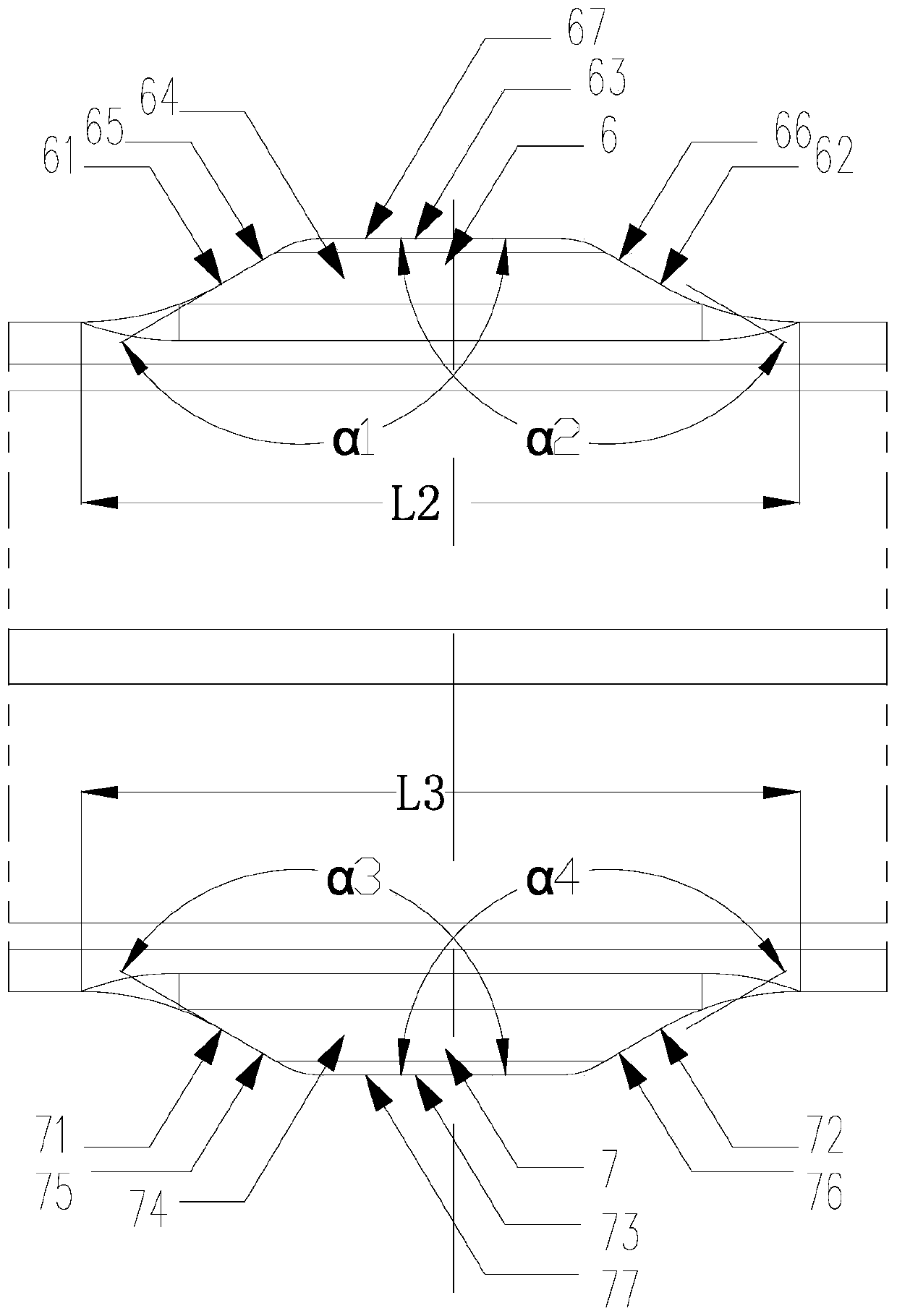

[0056]In this embodiment, the first cutting unit 6 includes a first front end surface 61, a first rear end surface 62 and a first side surface 63, and the first side surface 63 intersects with the first front end surface 61 and the first rear end surface 62 to form a first front side The cutting edge 68 and the first rear side cutting edge 69, the second cutting unit 7 includes a second front end surface 71, a second rear end surface 72 and a second side surface 73, the second side surface 73 and the second front end surface 71 and the secon...

Embodiment 3

[0063] Such as Figure 9 As shown, the cutting tool of this embodiment includes a cutter body 16, and the cutter body 16 is provided with a sipe 17. The cutting tool also includes the grooving blade in the above-mentioned embodiment 1, and the sipe 17 includes a groove end positioning surface 171, a groove front The side positioning surface 172 and the groove rear side positioning surface 173, the groove end positioning surface 171 can be positioned and matched with the lower horizontal positioning surface 31 or the lower vertical positioning surface 32, and the groove front side positioning surface 172 can be positioned with the lower horizontal positioning surface 31 or the lower vertical positioning surface. The positioning surface 32 is matched, and the positioning surface 173 on the rear side of the groove can be positioned and matched with the upper horizontal positioning surface 21 or the upper vertical positioning surface 22, and the blade 1 is elastically clamped in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com